Tobacco primary curing system with solar photo-thermal-photovoltaic-natural gas complementary energy supply

A solar photovoltaic and natural gas technology, applied in tobacco, tobacco preparation, application, etc., can solve the problem of less research, achieve clean energy, reduce investment and operating costs, and save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

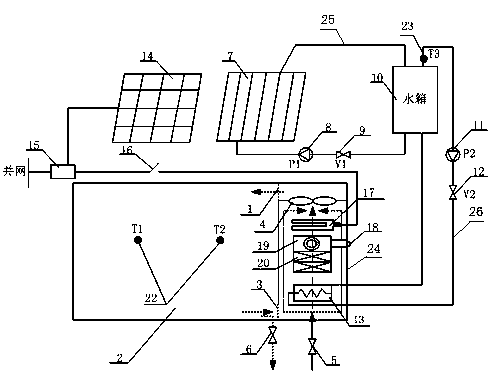

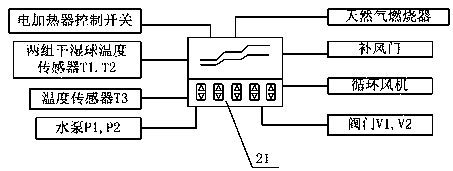

Method used

Image

Examples

Embodiment

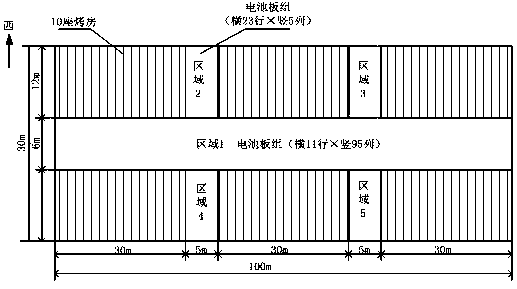

[0059] The flue-cured tobacco area takes Kunming City, Yunnan Province as an example. It is located at 25° north latitude and 103° east longitude. The local flue-cured tobacco months are from July to September. see image 3 , every 10 dense barns are connected as a whole, a total of 60 seats in 2 rows and 3 columns, and the total roof area is about 3000m2 2 . The smoke loading capacity of a single barn is 4000kg.

[0060] Preliminary design of solar thermal heating module:

[0061] In line with the principle of solar thermal heating priority, the preliminary calculation of solar collectors is carried out first. According to experience and estimates, the temperature of water heated by solar collectors can reach up to 90°C, and water at 90°C can heat air at 20°C to a maximum of about 50°C, so solar collectors can only provide heat alone in the early stage of tobacco leaves. . Therefore, the design standard of the solar collector is that in the case of sufficient light durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com