Bipolar plate sealing process for fuel cells

A fuel cell cathode and fuel cell technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of UV curing difficulties, invisible adhesive joints, etc., to avoid blocking the cooling flow field, clean and beautiful appearance, and stack Fast and accurate temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] According to the shape of the bipolar plate, the gluing area of the stencil is made. The gluing area on the stencil is indented by 1mm from the outer contour of the bipolar plate, and the other areas of the plate are glued as a whole. Use 150-mesh polyester mesh to make the mesh panel, and use oily photosensitive glue to seal the mesh. The prepared stencil is fixed on the screen printing equipment, and the method of screen printing is adopted. After the glue is applied, the cathode and anode plates are combined, placed in the limit tooling, and the limit tool is placed in a hot press for heat curing , the temperature of the hot press is 150 degrees, the pressure is 0.7 MPa, the curing time is 30 minutes, cooling, and the bipolar plate bonding is completed.

Embodiment 2

[0024] A fuel cell bipolar plate sealing process adopts the following steps:

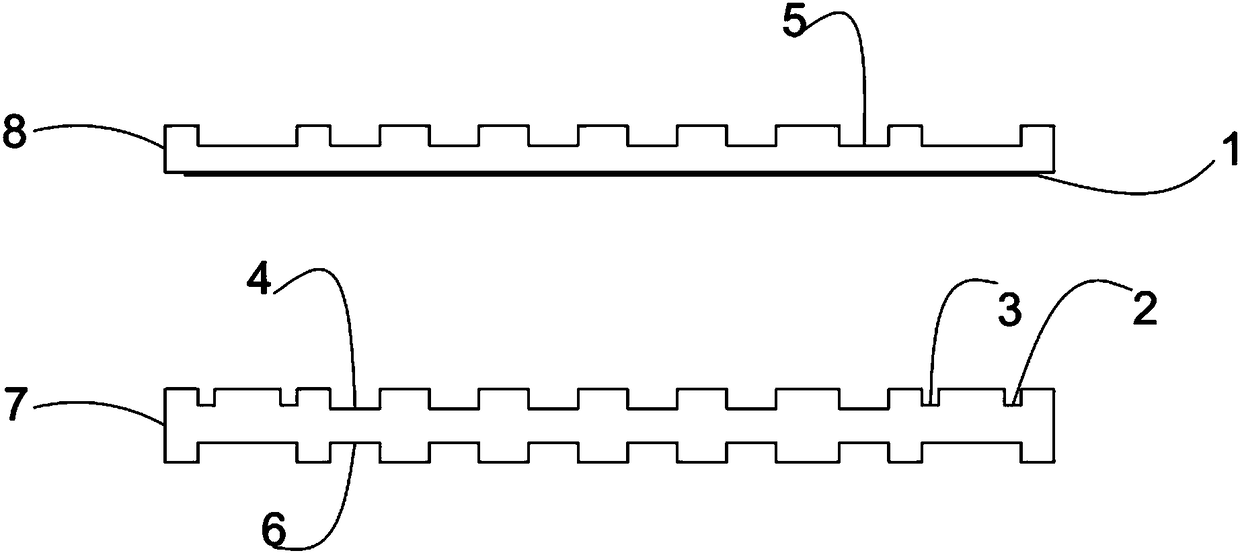

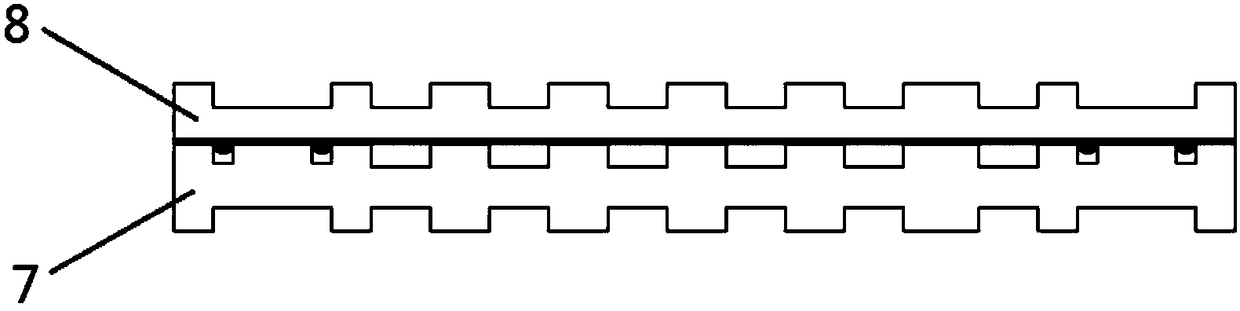

[0025] (1) Process a circle of the second glue overflow groove 3 and the first glue overflow groove 2 on the periphery and outer contour of the coolant flow field 4 on the fuel cell anode plate 7, and also have an oxidant flow field 6 on the anode plate 7 ;

[0026] (2) Coating conductive glue 1 on the smooth surface of cathode plate 8, the other side is fuel flow field 5, as figure 1 As shown, the conductive adhesive is applied by screen printing equipment, and the printing screen used is a polyester screen with a mesh number of 120. The glue thickness is 0.01mm;

[0027] (3) Place the anode plate and the surface of the cathode plate coated with conductive adhesive together in the limit tooling, put the limit tool into a hot press for hot pressing and curing, and control the temperature for hot pressing and curing to 120°C. The pressure is 0.1Mpa, the time is 90min, and the sealed connection is ...

Embodiment 3

[0029] A fuel cell bipolar plate sealing process adopts the following steps:

[0030] (1) Process a circle of the second glue overflow groove 3 and the first glue overflow groove 2 on the periphery and outer contour of the coolant flow field 4 on the fuel cell anode plate 7, and also have an oxidant flow field 6 on the anode plate 7 ;

[0031] (2) Coating conductive glue 1 on the smooth surface of cathode plate 8, the other side is fuel flow field 5, as figure 1 As shown, the conductive adhesive is coated with screen printing equipment, and the printing screen used is a polyester screen with a mesh number of 200. Glue thickness is 0.05mm;

[0032] (3) Place the anode plate and the surface of the cathode plate coated with conductive adhesive together in the limit tooling, put the limit tool into a hot press for hot pressing and curing, and control the temperature for hot pressing and curing to 120°C. The pressure is 1Mpa, the time is 30min, and the sealed connection is compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com