Underground parking garage epoxy mortar abrasion-resisting floor and construction method

An epoxy mortar and construction method technology, applied in the field of flooring, can solve the problems of not being able to make according to requirements, waste of technical materials, unqualified technology, etc., and achieve the effects of good bonding strength, short construction period, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

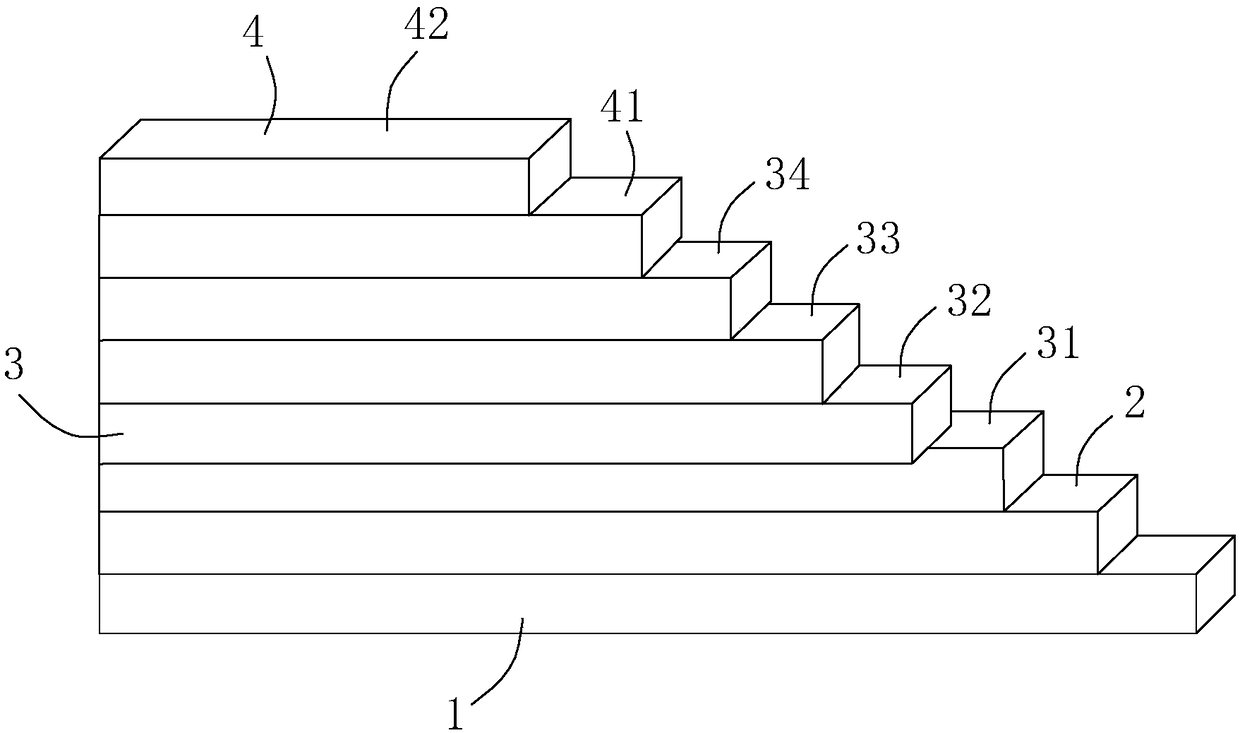

[0052] Embodiment 1: An epoxy mortar wear-resistant floor of an underground parking garage, such as figure 1 As shown, it includes an epoxy mortar wear-resistant floor laid on a concrete base 1, and the epoxy mortar wear-resistant floor includes a sealing primer layer 2, an epoxy mortar layer 3 and an epoxy surface layer 4 sequentially laid from bottom to top.

[0053] The sealing primer layer 2 is a high-permeability epoxy resin primer layer evenly painted on the concrete base 1, and the high-permeability epoxy resin primer is evenly painted on the surface of the concrete base 1, and penetrates to the concrete 2-4mm Next, to enhance the adhesion between the floor and the concrete base 1.

[0054] The high-permeability epoxy resin primer is composed of A component and B component. A component includes modified epoxy resin, reactive diluent, penetrating agent and solvent, B component is curing agent, A component The weight ratio range of component B and component B can be sele...

Embodiment 2

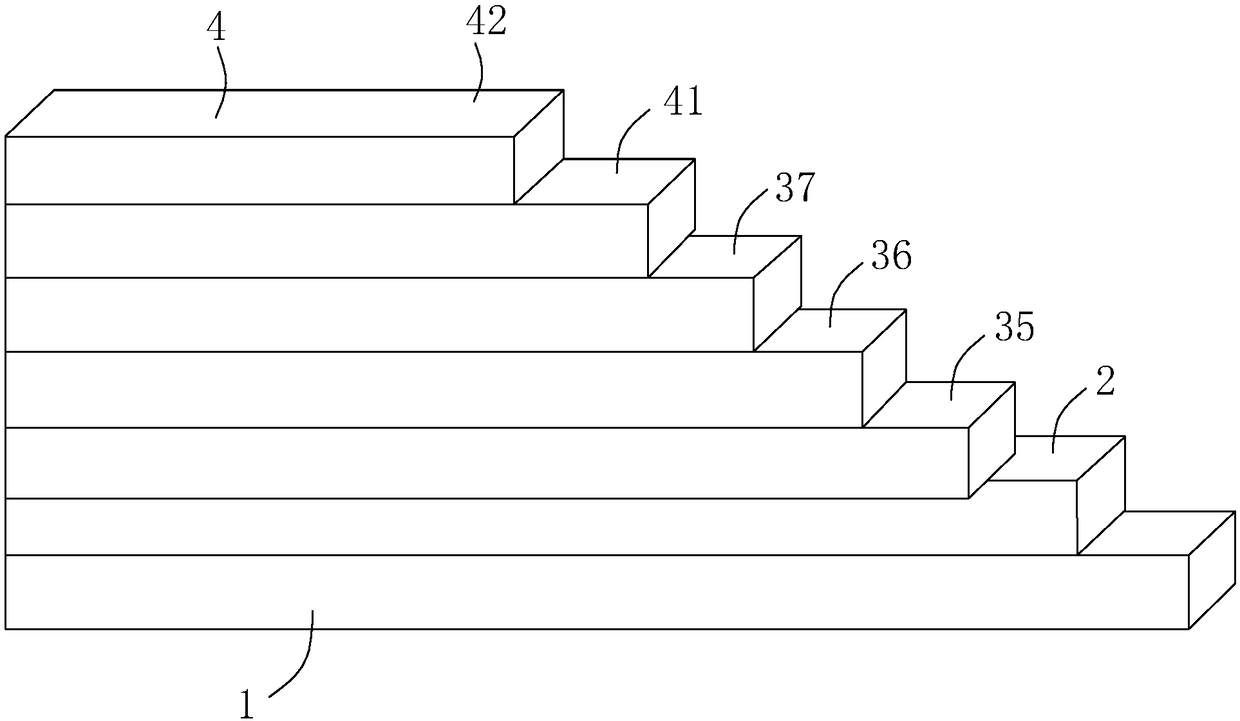

[0077] Embodiment 2: An epoxy mortar wear-resistant floor of an underground parking garage, such as image 3 As shown, the epoxy mortar layer 3 includes the third epoxy mortar layer 35, the third epoxy putty layer 36 and the sanding anti-skid layer 37 arranged from bottom to top. After brushing the third epoxy mortar layer 35, brushing The third epoxy putty layer 36 ensures the characteristics of high strength, high toughness and high impact resistance of the floor, and the anti-skid layer 37 of sanding improves the anti-skid property of the floor, so that the floor is suitable for use occasions with high anti-skid requirements .

[0078] The thickness of the third epoxy mortar layer 35 can be selected as 2-4mm, and the thickness of the third epoxy putty layer 36 can be selected as 0.1-0.4mm. In the present embodiment, the thickness of the third epoxy mortar layer 35 is 4mm , the thickness of the third epoxy putty layer 36 is 0.4mm, so that the epoxy mortar has good strength,...

Embodiment 3

[0085] Embodiment 3: An epoxy mortar wear-resistant floor of an underground parking garage, such as Figure 5 and Image 6 As shown, the sealing primer layer 2 is provided with a load-bearing layer 5, the load-bearing layer 5 is spliced by a plurality of steel plates 51, the load-bearing layer 5 is provided with a waterproof coating 6, and the waterproof coating 6 is provided with an elastic rubber cushion layer 7 , the elastic rubber cushion layer 7 is provided with a drainage pad 8 that is arc-shaped and forms a drainage channel with the waterproof coating 6. The drainage pad 8 is provided with a plurality of drainage holes 81, and the drainage pad 8 and the elastic rubber cushion layer 7 There is an adhesive layer 9 between them.

[0086]The load-bearing layer 5 can play the role of stabilizing the concrete base 1, and the waterproof coating 6 can effectively prevent corrosion of the steel plate 51. After the accumulated water on the floor penetrates into the drainage pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com