Liquid nutritional composition comprising micellar casein and hydrolysed whey protein

A technology of hydrolyzed whey protein and nutritional composition, which is applied in the fields of peptide/protein components, animal protein processing, medical preparations containing active ingredients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0181] Embodiment 1: the preparation of liquid nutritional composition

[0182] Several liquid nutritional compositions containing the ingredients shown in Table 1 were prepared.

[0183] Table 1: Ingredients present in liquid nutritional compositions

[0184]

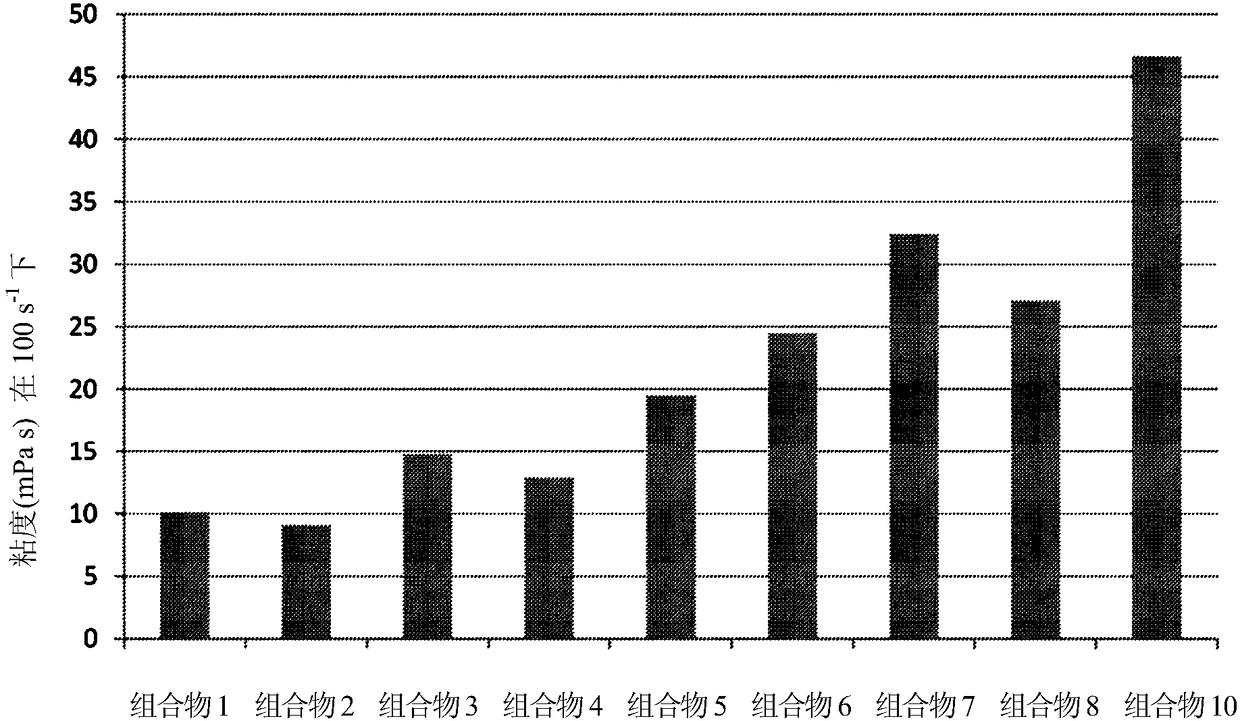

[0185] Liquid nutritional compositions 1-7 according to the present invention as shown in Table 2 and comparative compositions 8-12 as shown in Table 3 were prepared.

[0186] Table 2: Liquid nutritional compositions according to the invention having a protein content of 10 to 15 g / 100 ml of composition

[0187]

[0188]

[0189]a The amounts of micellar casein and hydrolyzed whey protein are expressed in % by weight based on total protein dry matter. The sources of micellar casein and hydrolyzed whey protein are shown in parentheses.

[0190] b Refit MCI 88 is a source of micellar casein, comprising 88 wt. % protein based on total dry matter and approximately 90-95 wt. % micellar protein based on protein...

Embodiment 2

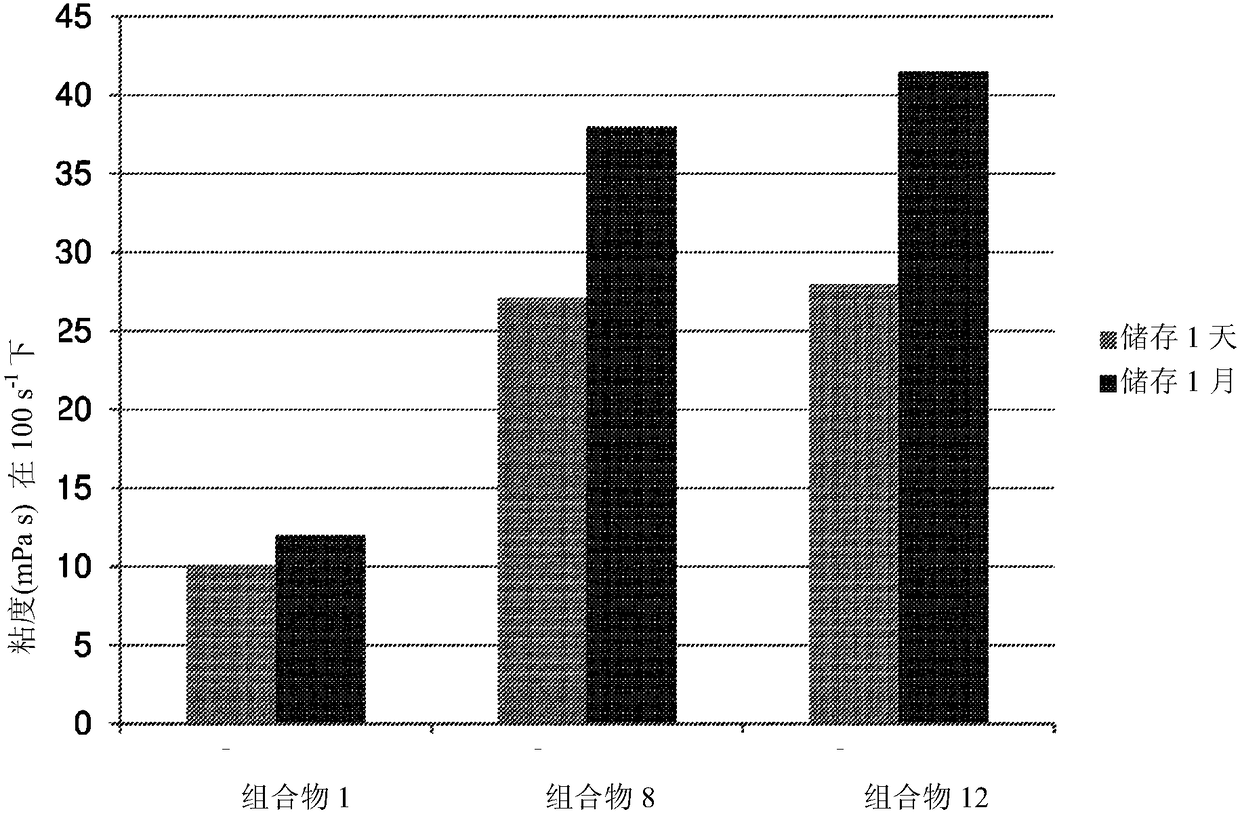

[0213] Embodiment 2: liquid nutritional composition

[0214] The liquid nutritional composition according to the present invention is prepared by preparing a solution of protein in demineralized water, adding a carbohydrate source, adding mineral solution to the protein solution (optional), then raising the temperature of the mixture to 40-80°C, preferably 50- It is prepared at a temperature of 70°C, most preferably at a temperature of about 60°C. One or more fat sources are optionally added and the mixture is optionally homogenized. The liquid fat stream is optionally preheated to a temperature of about 50-70°C, for example 60°C. After adding the fat the mixture is cooled to preferably ambient temperature (approximately 20° C.) and the pH is adjusted if necessary. The mixture is then subjected to a homogenization step, preferably a 2-stage homogenization step. The nutritional composition thus obtained is then sterilized, for example at 121° C. for 10 minutes.

[0215] A...

Embodiment 3

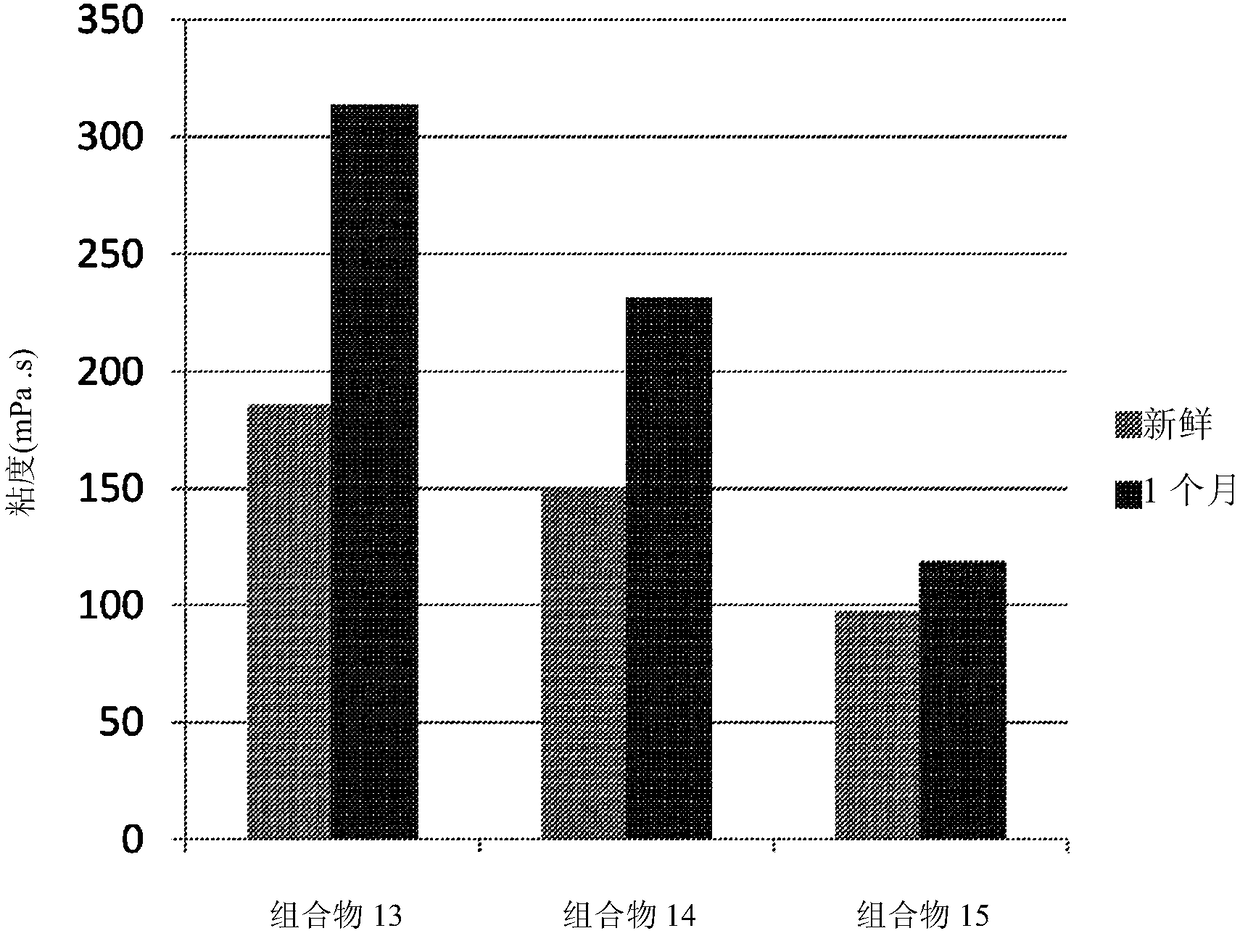

[0228] Example 3: Liquid Nutritional Compositions 14-15 and Comparative Composition 13

[0229] Liquid nutritional compositions 13 (comparative example) and 14-15 were prepared from the ingredients shown in Table 8 and had nutritional compositions as shown in Table 9.

[0230] Comparative composition 13 contained no hydrolyzed whey protein, and this composition contained only micellar casein as protein. Compositions 14 and 15, both according to the invention, contained 85% by weight (composition 14) and 70% by weight (composition 15) of micellar casein, based on total protein.

[0231] Compositions 13-15 were prepared on a 2 liter scale. Homogenization was carried out in a Homogenizer Bosch at a flow rate of 60 l / h at 70° C. and a pressure of 200 / 50 bar. Thermal stability was tested in the retort test. Compositions 13-15 are thermally stable. Thermal stability was analyzed by visual observation and the thermally stable solutions were homogeneous and did not exhibit stabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com