Patents

Literature

41 results about "Micellar casein" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The micellar casein is a slow releasing source of protein, comprising lower carbohydrates and fats. They constitute bioactive micro-fractions trace compounds, which are important for growth improving our immune system. Micellar casein, after ingesting, breaks down into high quality branched chain amino acids (BCAAs).

Protein-dense micellar casein-based liquid enteral nutritional composition

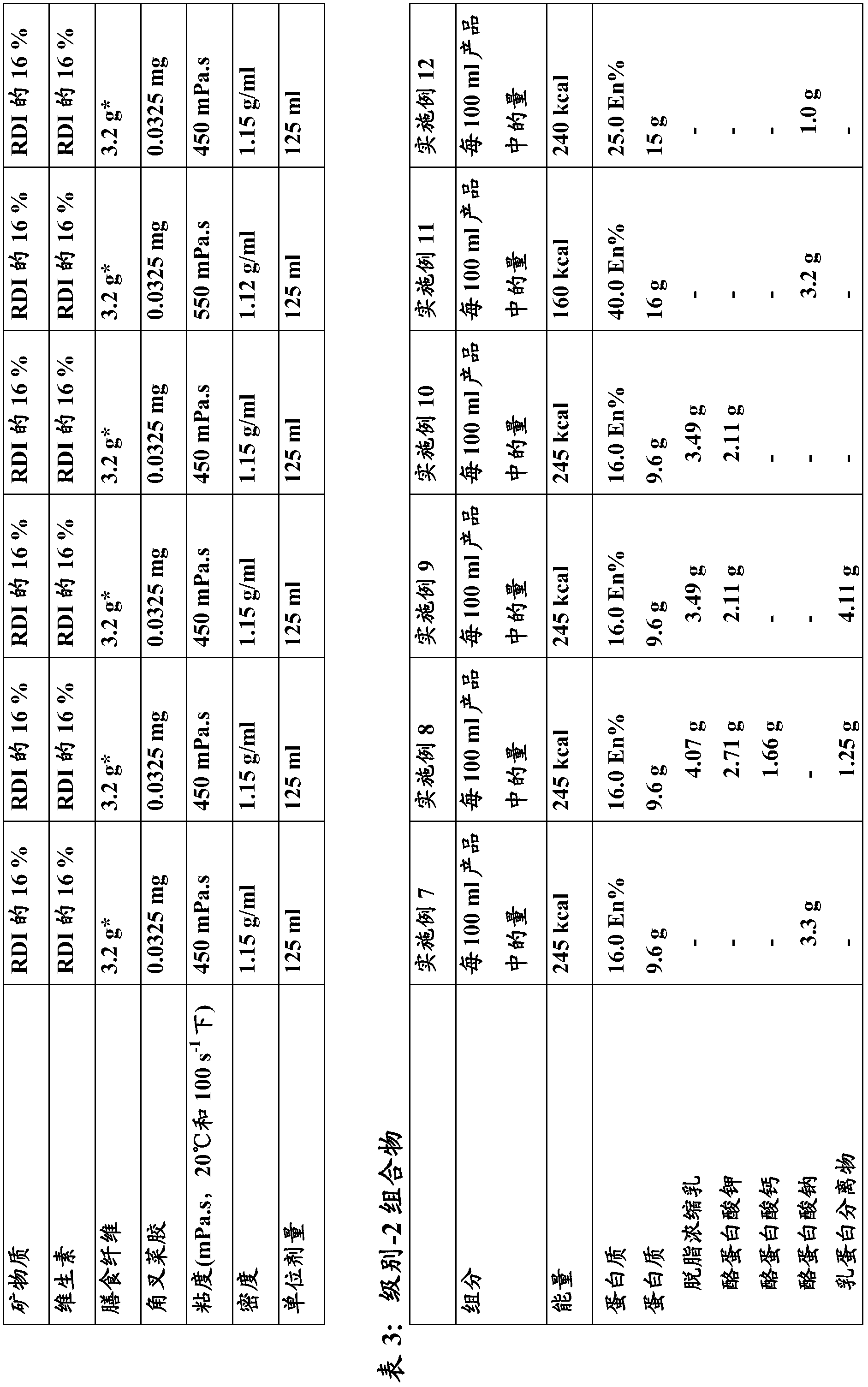

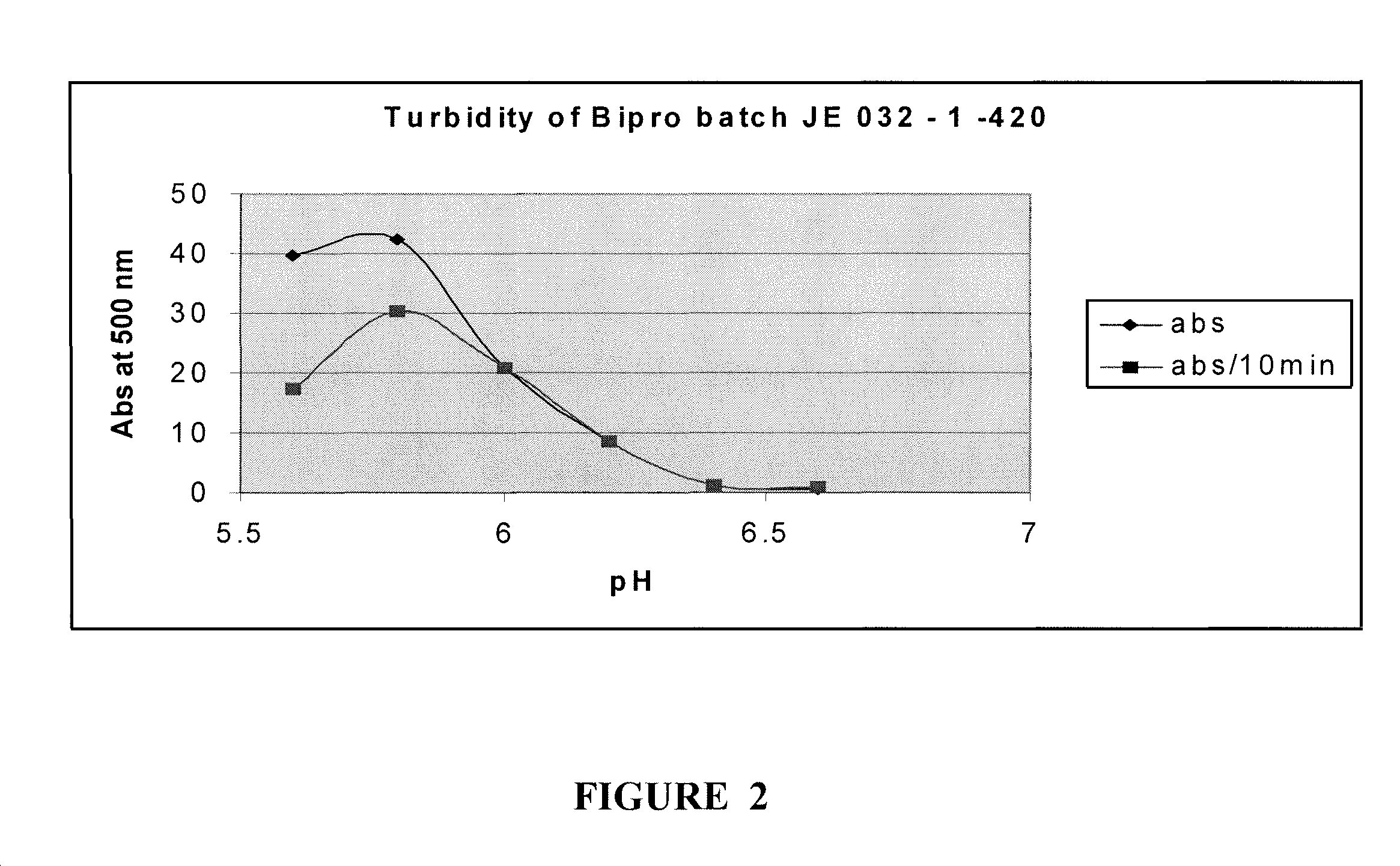

InactiveUS20110008485A1High in proteinDesired viscosity of the compositionMilk preparationMetabolism disorderMicellar caseinEvaporation

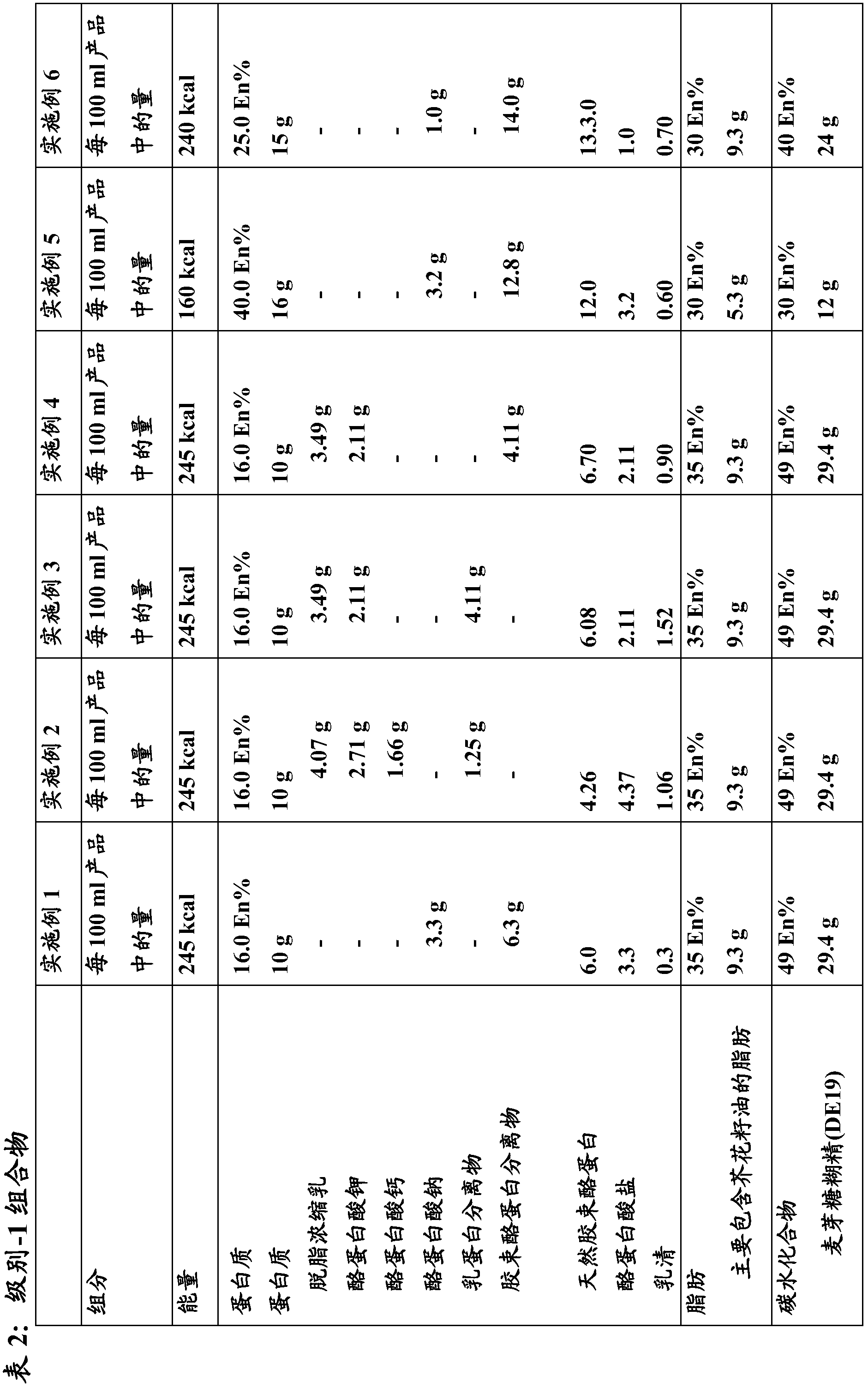

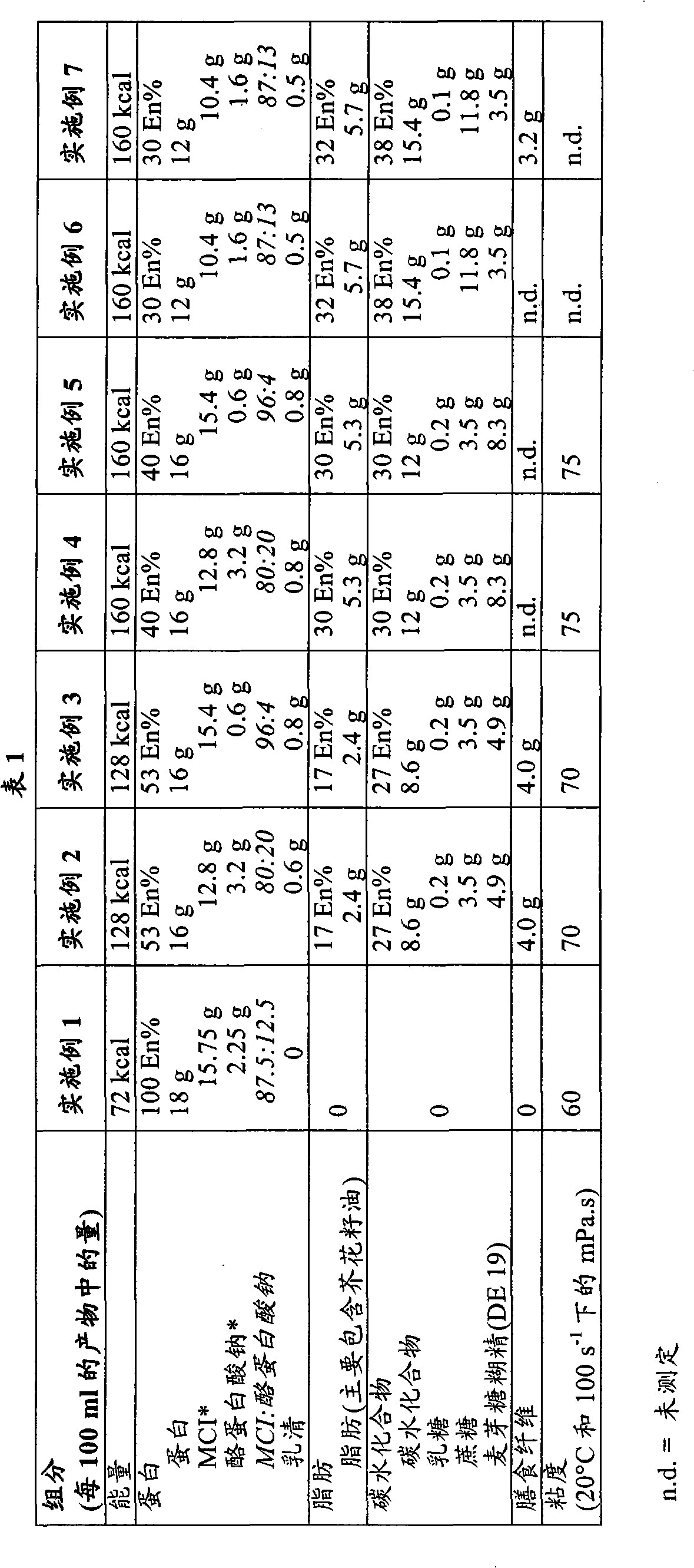

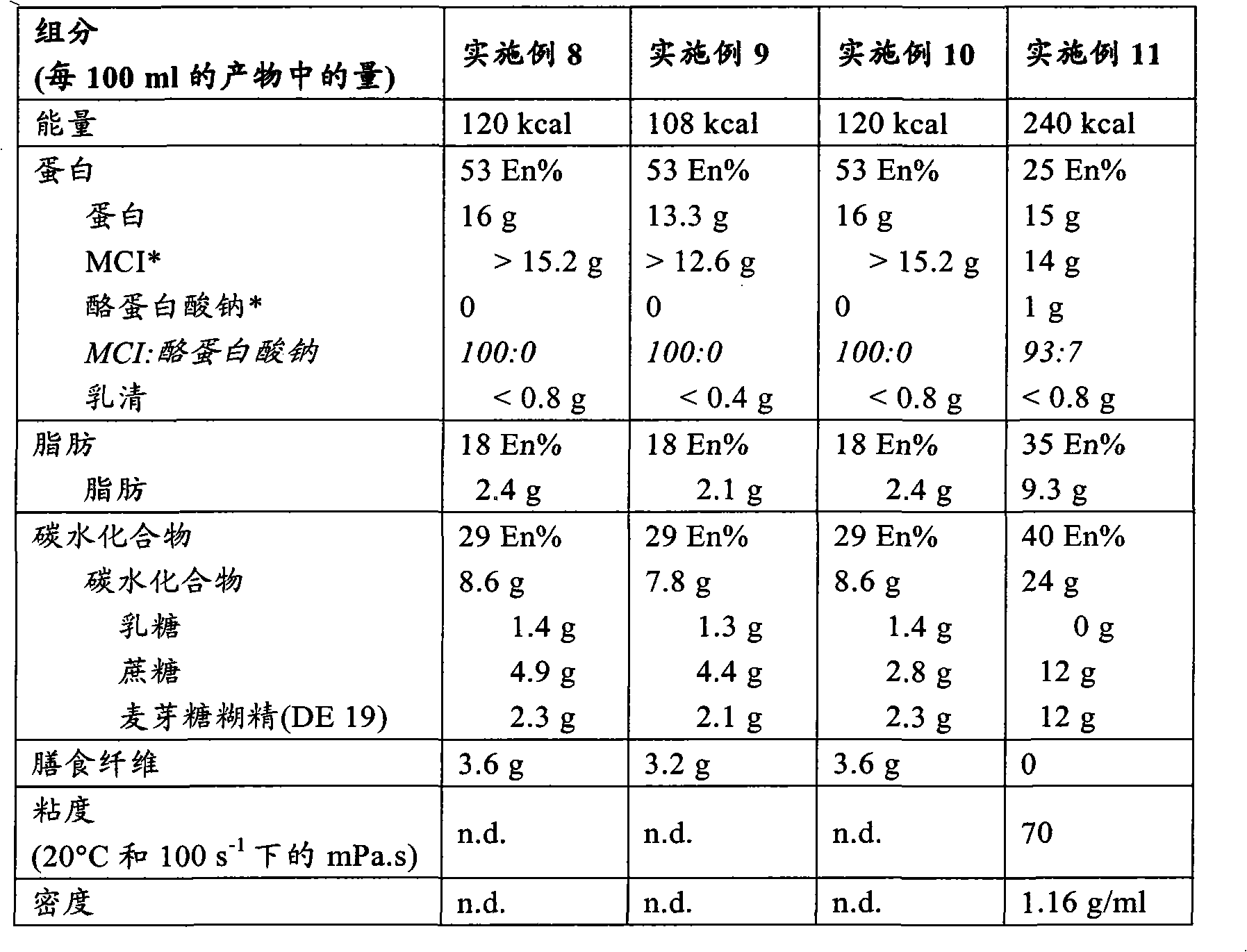

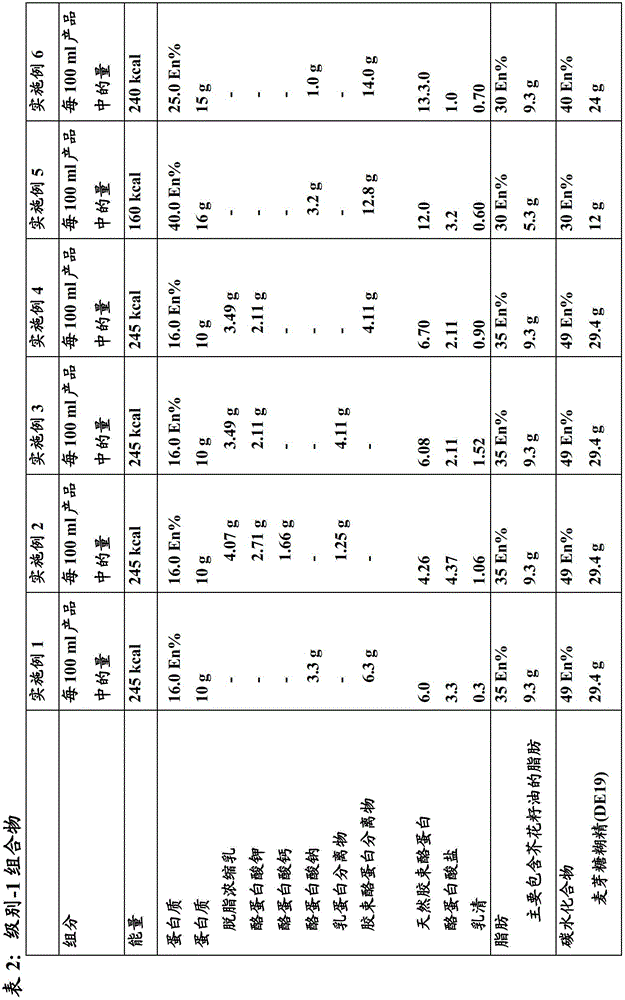

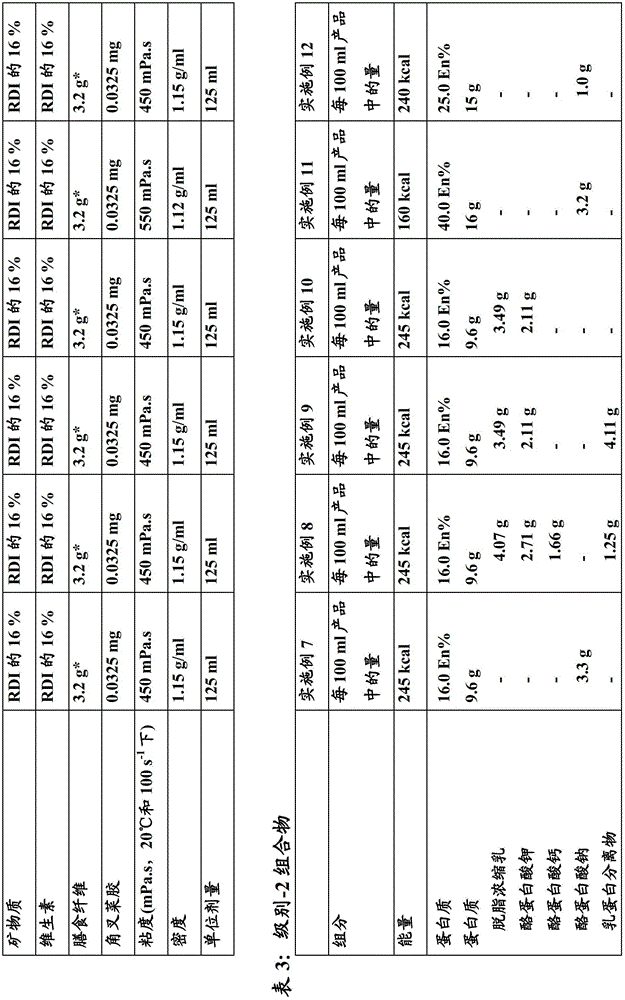

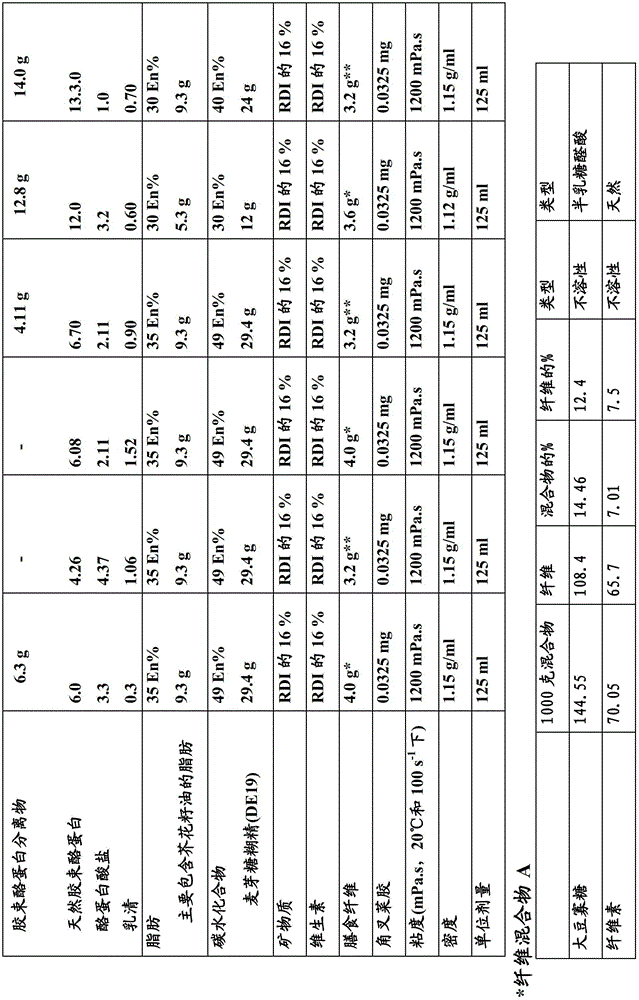

Protein-dense micellar casein-based liquid enteral nutritional composition are provided that contain micellar casein and optionally caseinate. Liquid enteral nutritional compositions are disclosed comprising 10 to 20 g of protein per 100 ml of the composition, in which all or a major part of said protein comprises native micellar casein. Also, a method is disclosed for producing the composition according to the invention, comprising a step wherein an aqueousprotein solution in which all or a major part of said protein comprises native micellar casein, is subjected to an evaporation step.

Owner:NUTRICIA

Nanoparticulated whey proteins

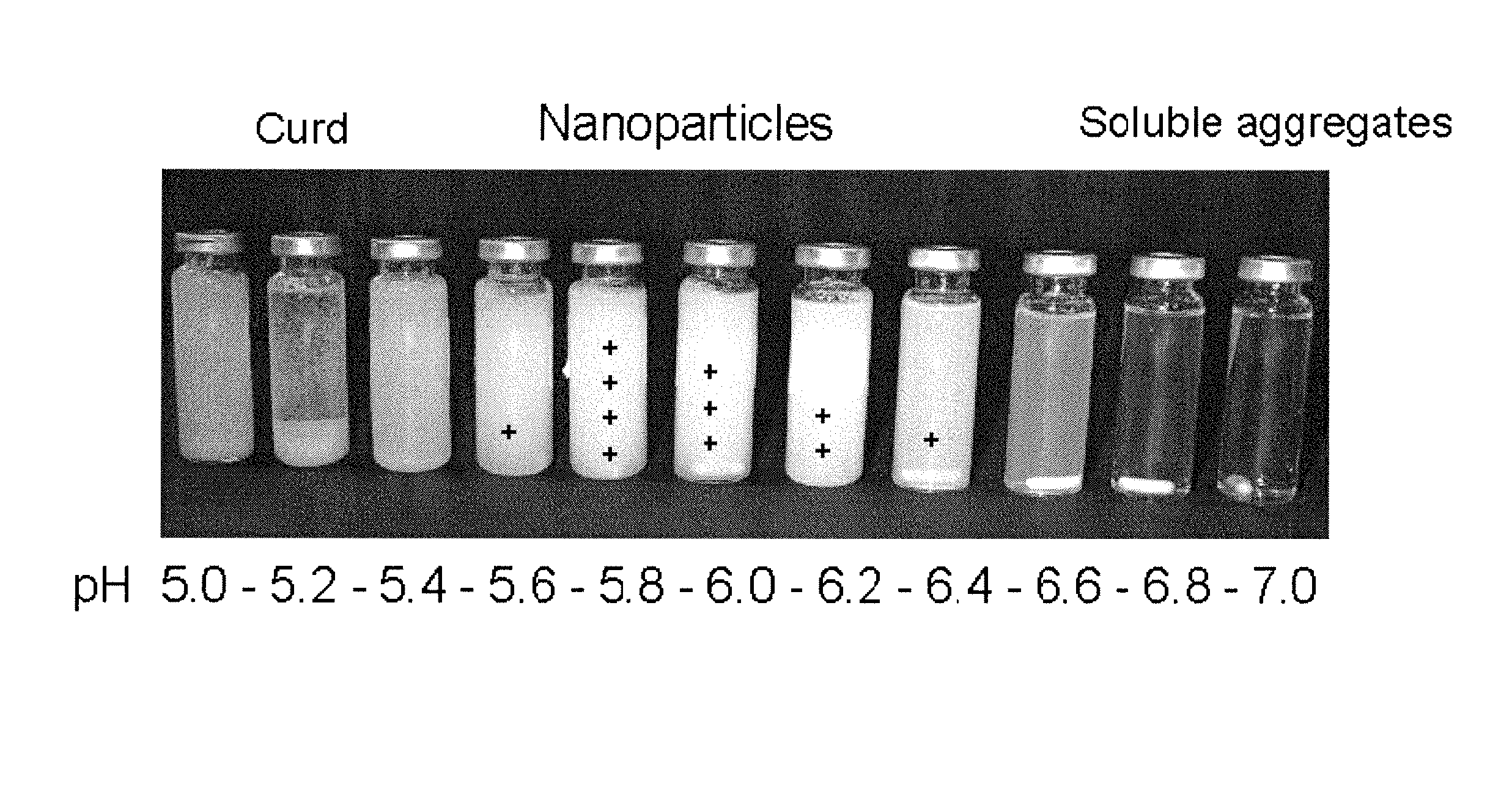

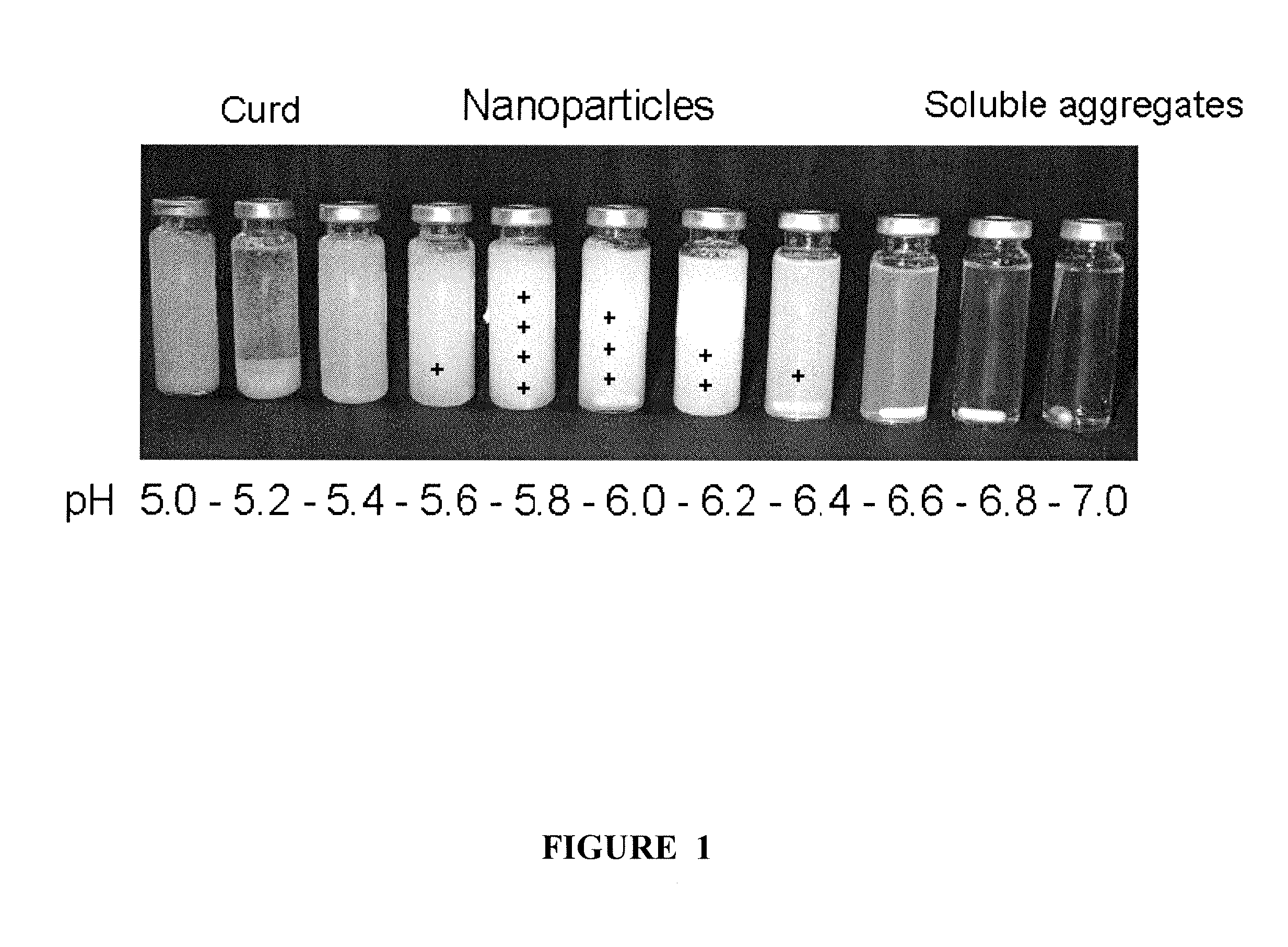

ActiveUS20070231453A1Protein composition from fishFood ingredient nanoparticlesNanoparticleWhey protein

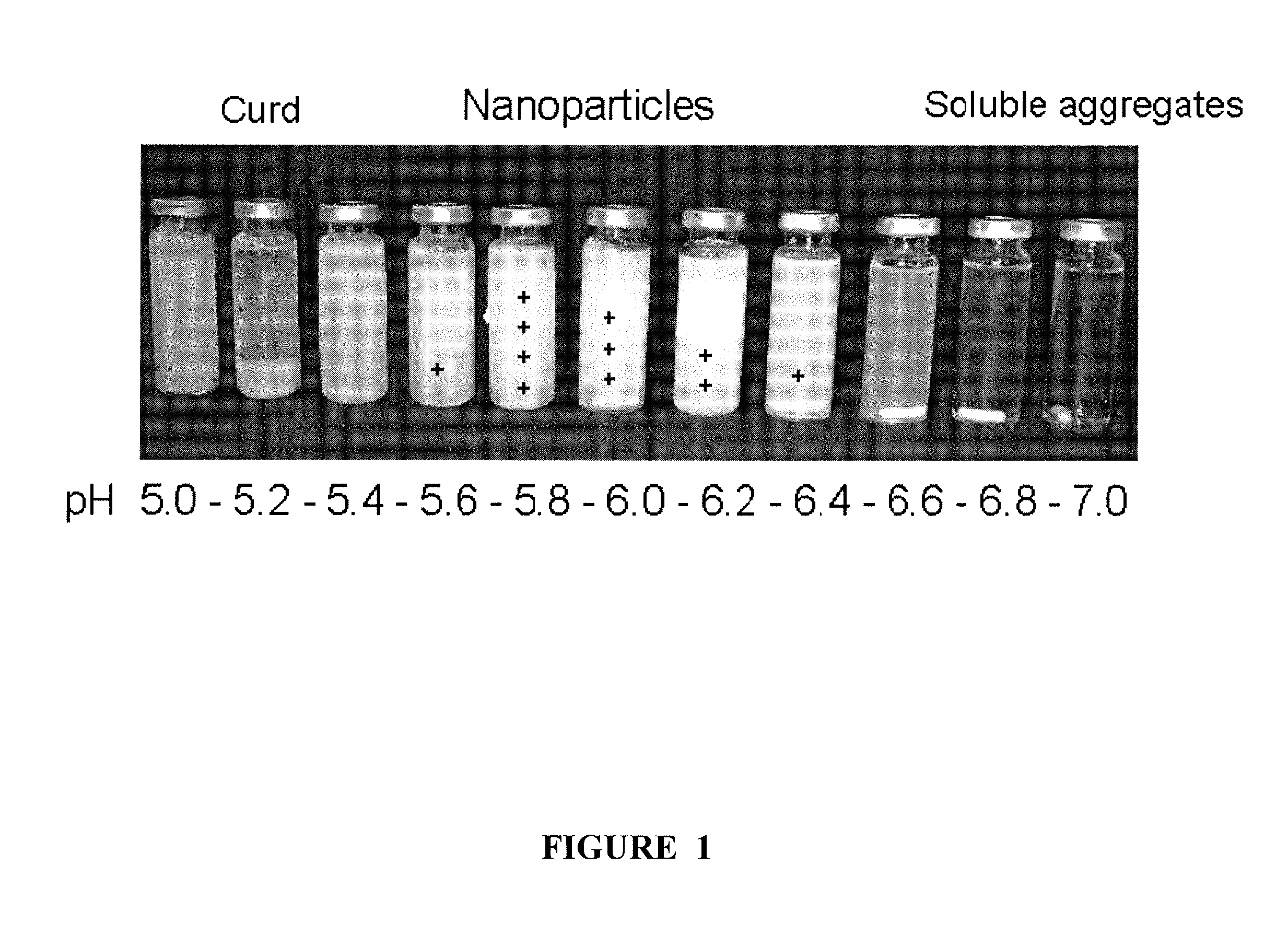

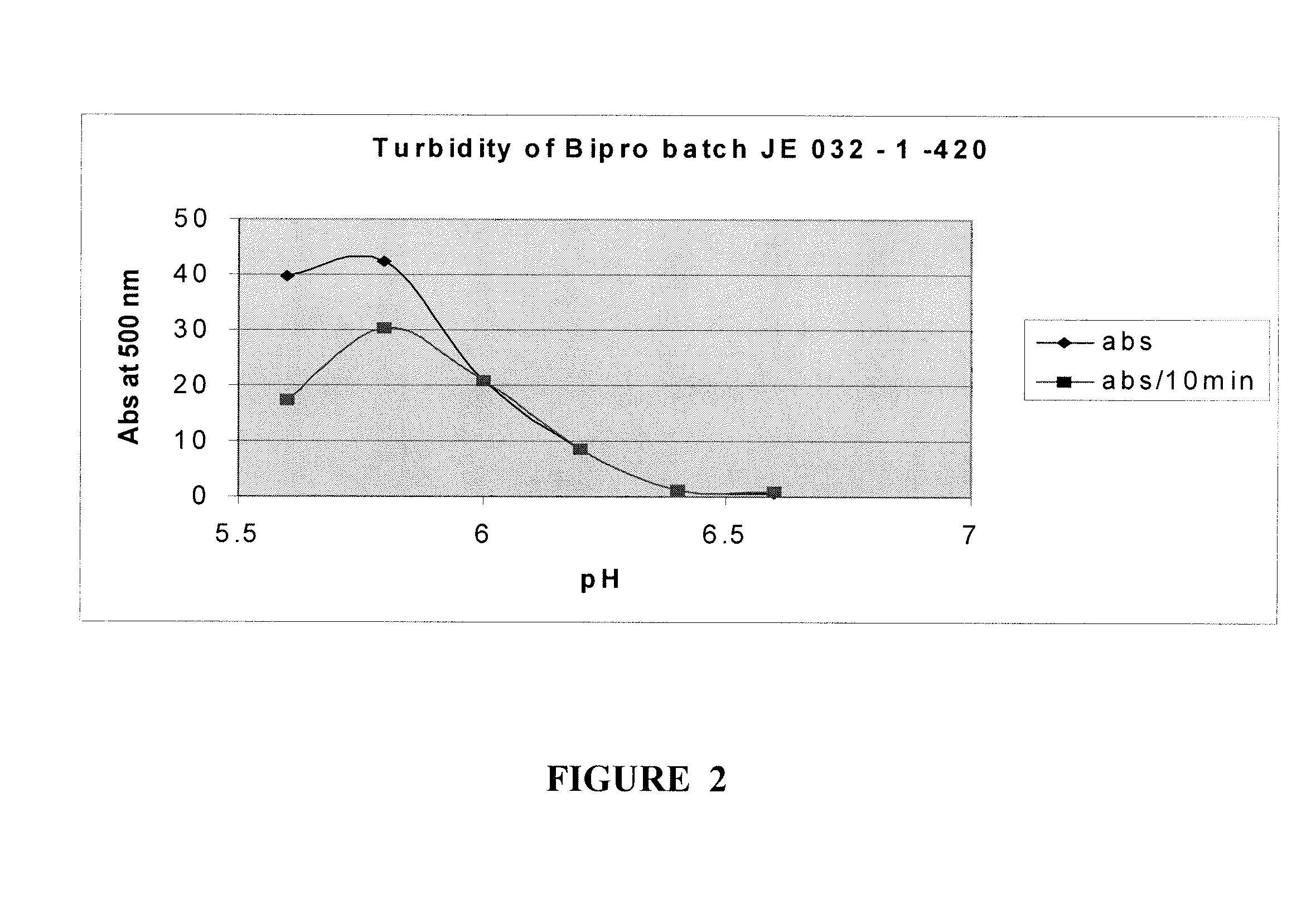

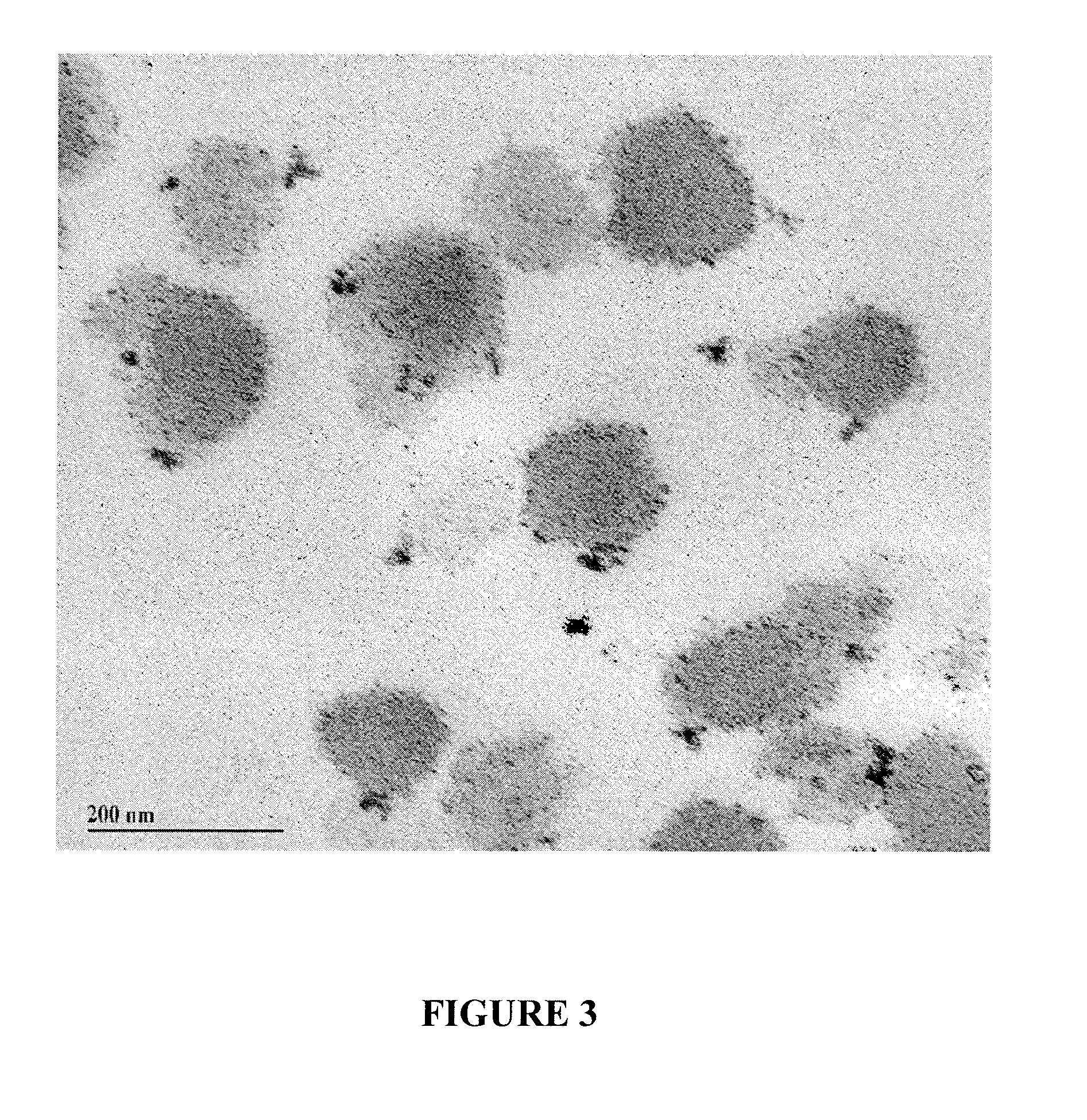

The present invention relates to a method for producing whey proteins in nanoparticulated form and to the nanoparticulated whey proteins thus obtained. Specifically, the present invention pertains to the use of these nanoparticulated whey proteins as emulsifiers, fat substitute, micellar casein substitute, whitening, foaming, texturizing and / or filling agents.

Owner:SOC DES PROD NESTLE SA

Liquid enteral nutritional composition with a low monovalent metal ion content

ActiveUS20120142587A1High in proteinLow viscosityPeptide/protein ingredientsMetabolism disorderIon contentProtein solution

Heat-treated liquid enteral nutritional composition with a low monovalent metal ion content are provided that contain micellar casein and optionally caseinate, and in which the total amount of monovalent metal ions is less than 25 mg / g of protein. Also, heat-treated liquid enteral nutritional compositions are disclosed comprising 10 to 20 g of protein per 100 ml of the composition, in which all or a major part of said protein comprises micellar casein. Also, a method is disclosed for producing the composition according to the invention, comprising a step wherein an aqueous protein solution in which all or a major part of said protein comprises micellar casein, is subjected to an evaporation step.

Owner:NUTRICIA

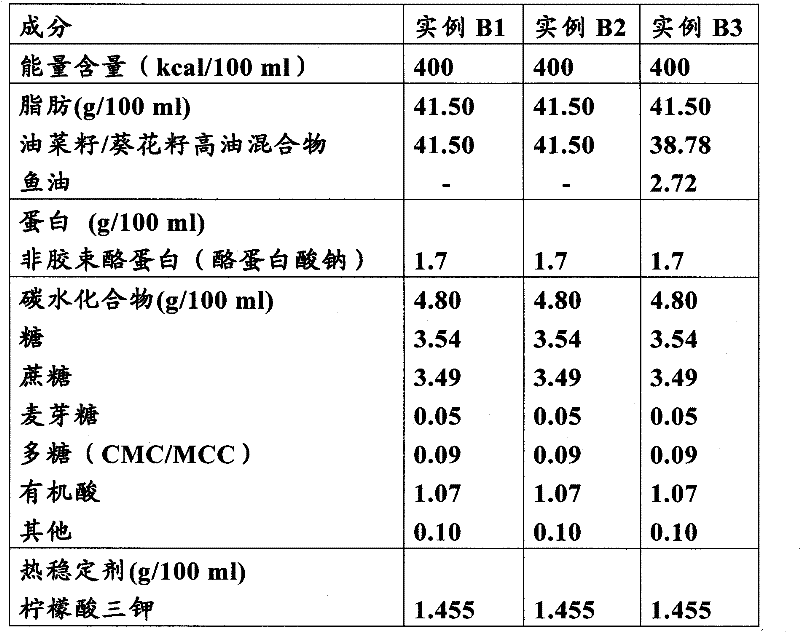

High energy liquid enteral nutritional composition

ActiveUS20110038982A1Increase energy contentHigh energyMilk preparationMetabolism disorderHigh energyMicellar casein

High energy and high protein liquid nutrition enteral compositions are provided that contain micellar casein and caseinate, an optionally a small amount of whey.

Owner:NUTRICIA

Pre-thickened compact liquid nutritional composition for dysphagia patients

The invention pertains to a liquid enteral nutritional composition with an energy density between 1.0 and 4.0 kcal / ml, a viscosity between 150 and 1800 mPas measured at a shear rate of 50 / second at 20 DEG C, comprising digestible carbohydrates and fat, wherein the composition further comprises at least one of (al) between 8-20 g protein per 100 ml of the composition, where micellar casein comprises at least 50wt% of the total protein content of the composition, or (a2) between 16-45 en% protein, where micellar casein comprises at least 50 % of the protein caloric content; and (b) anionic fibers capable of sequestering of calcium, and (c) carrageenan between 0.015 and 0.25 g per 100 ml of the composition, and its use for preventing / treating dysphagia, and / or treating / preventing malnourishment or undernourishment associated with dysphagia.

Owner:NUTRICIA

Nanoparticulated whey proteins

The present invention relates to a method for producing whey proteins in nanoparticulated form and to the nanoparticulated whey proteins thus obtained. Specifically, the present invention pertains to the use of these nanoparticulated whey proteins as emulsifiers, fat substitute, micellar casein substitute, whitening, foaming, texturizing and / or filling agents.

Owner:SOC DES PROD NESTLE SA

Protein-dense micellar casein-based liquid enteral nutritional composition

Protein-dense micellar casein-based liquid enteral nutritional composition are provided that contain micellar casein and optionally caseinate. Liquid enteral nutritional compositions are disclosed comprising 10 to 20 g of protein per 100 ml of the composition, in which all or a major part of said protein comprises native micellar casein. Also, a method is disclosed for producing the composition according to the invention, comprising a step wherein an aqueousprotein solution in which all or a major part of said protein comprises native micellar casein, is subjected to an evaporation step.

Owner:NV NUTRICIA

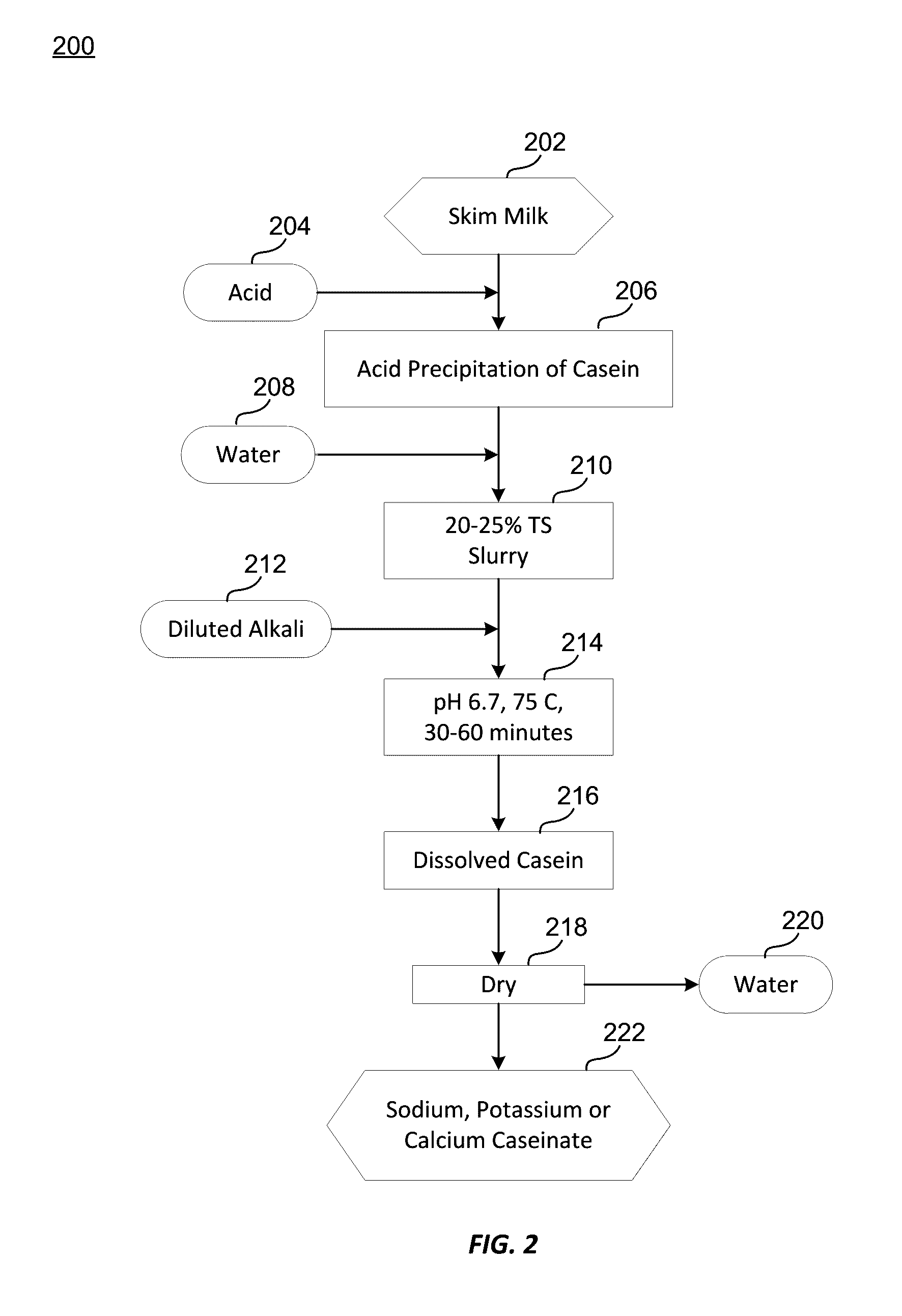

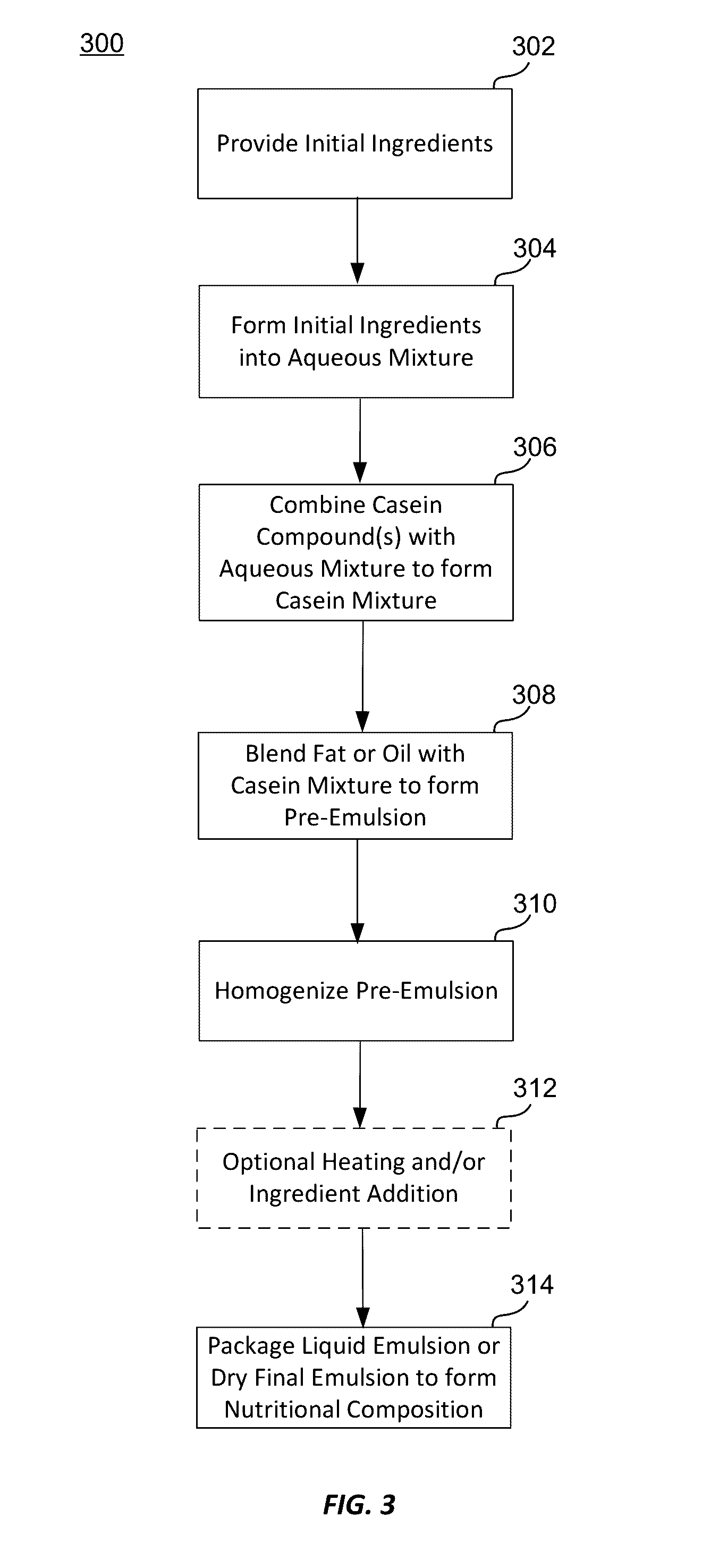

Micellar casein for corree creamers and other dairy products

InactiveUS20160374360A1Improve abilitiesGreat tasteMilk preparationSugar food ingredientsVegetable oilAdditive ingredient

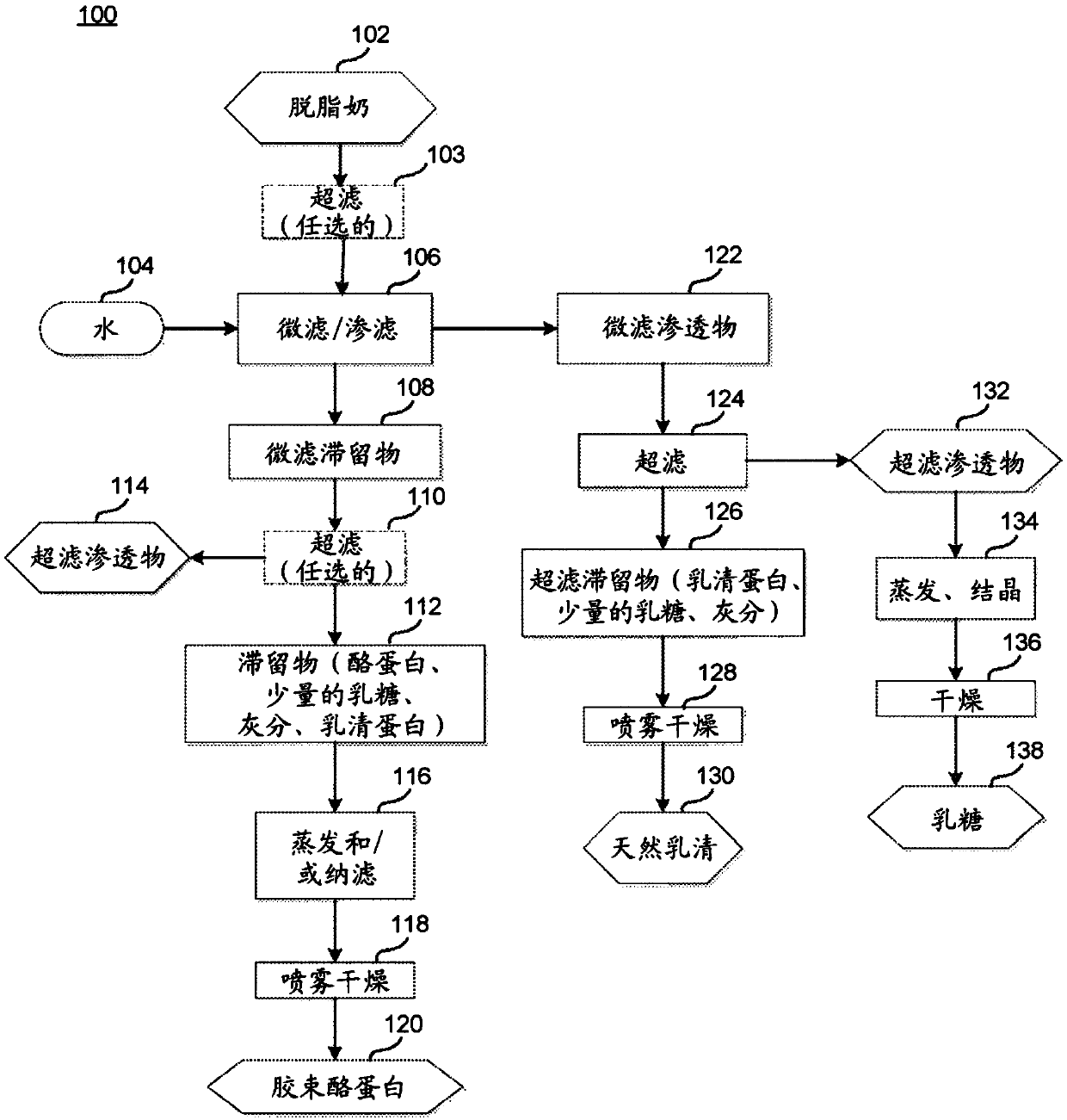

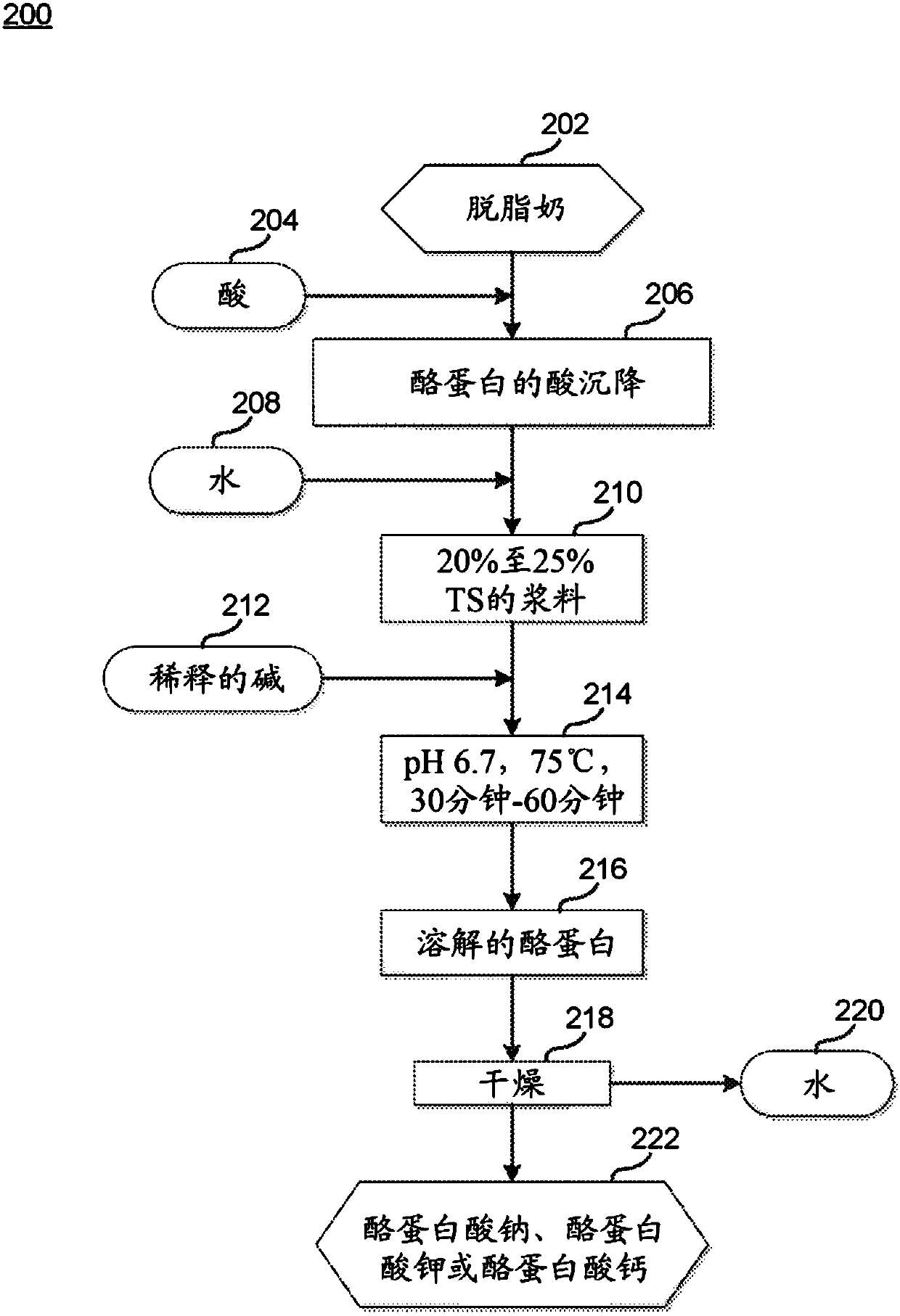

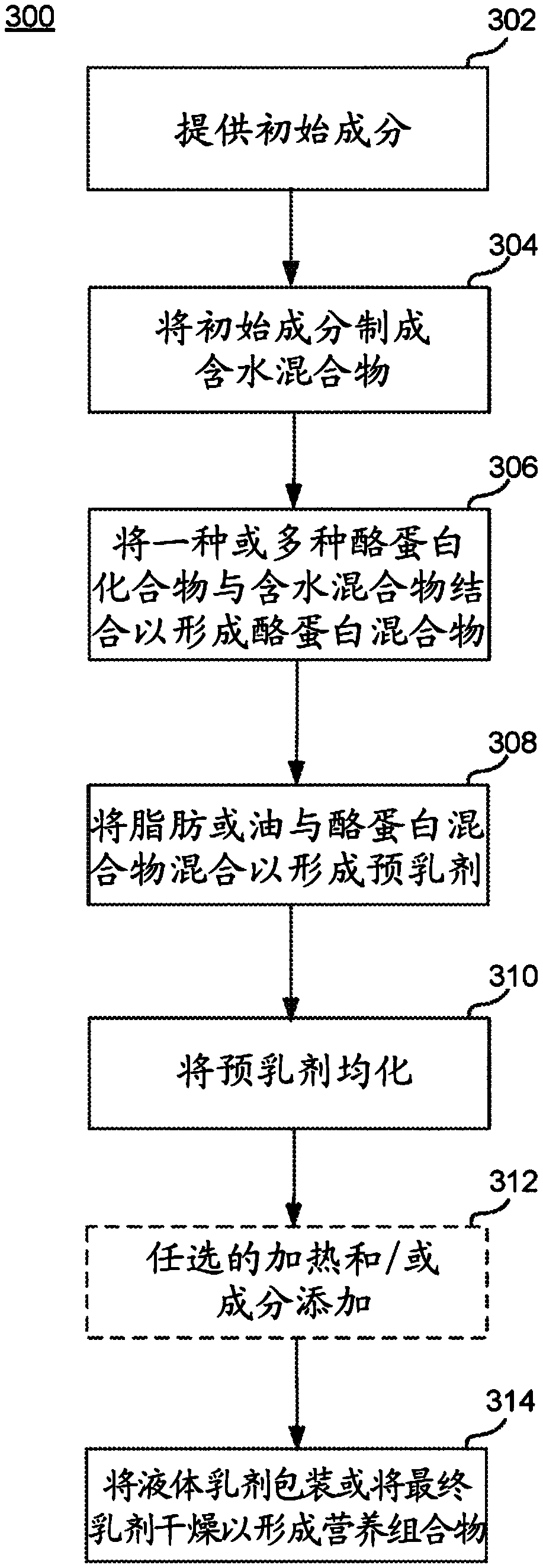

Nutritional compositions are described that include a casein compound that includes micellar casein, a vegetable oil, a sweetener, and an acidity regulator, among other ingredients. The nutritional compositions may be used as beverage creamers, such as coffee creamers. Also described are methods of making nutritional compounds that include micellar casein.

Owner:LEPRINO FOODS

High energy liquid enteral nutritional composition

ActiveUS8409651B2Increase energy contentHigh energyMilk preparationMetabolism disorderHigh energyMicellar casein

High energy and high protein liquid nutrition enteral compositions are provided that contain micellar casein and caseinate, an optionally a small amount of whey.

Owner:NV NUTRICIA

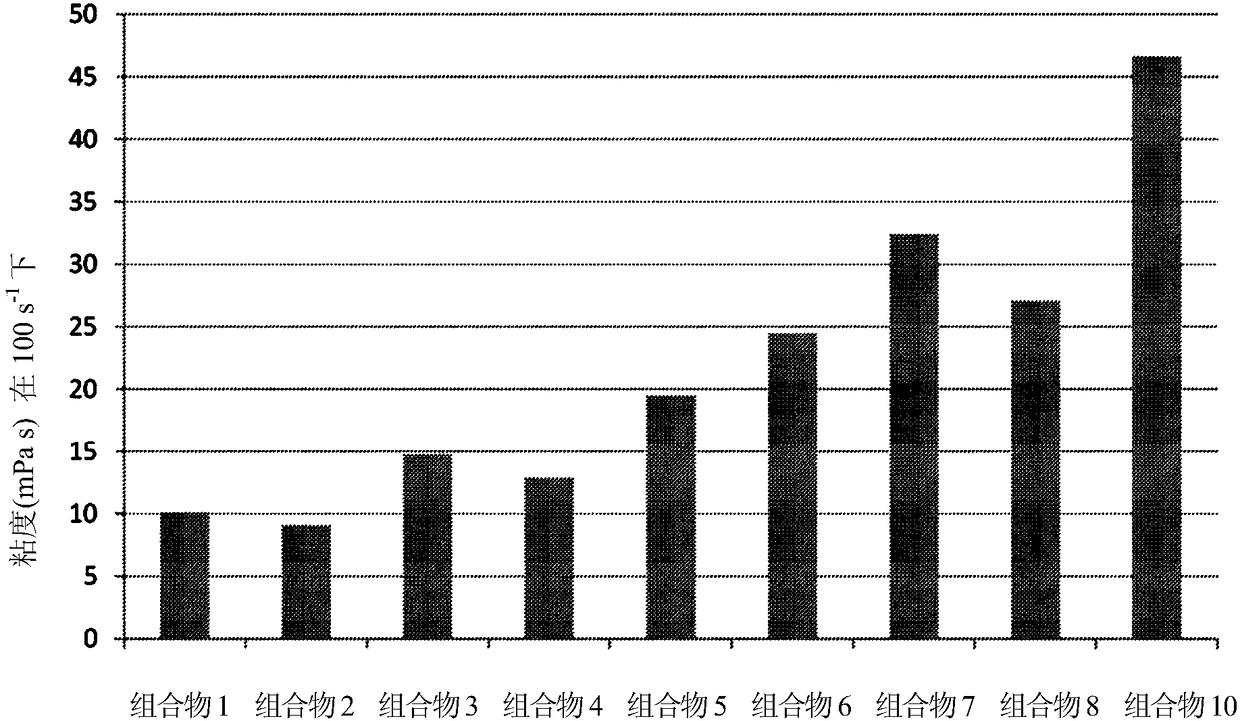

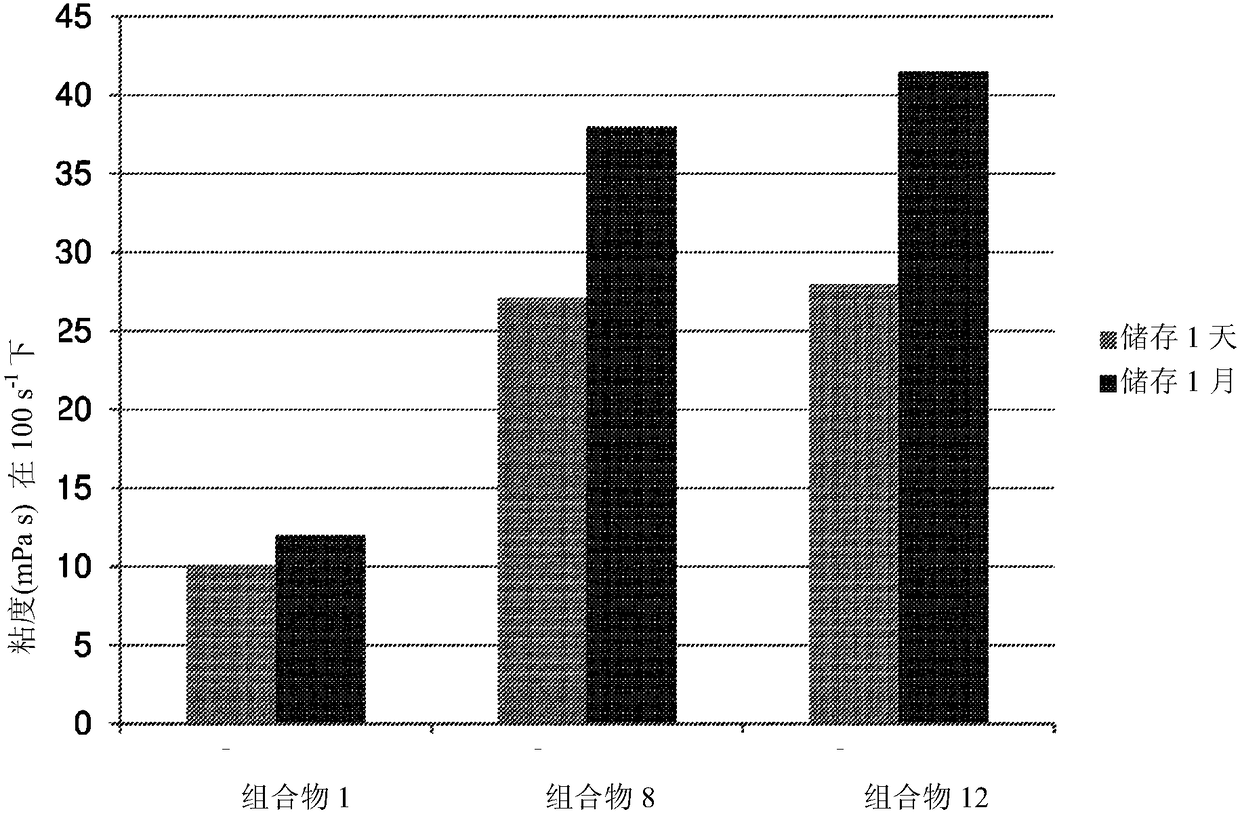

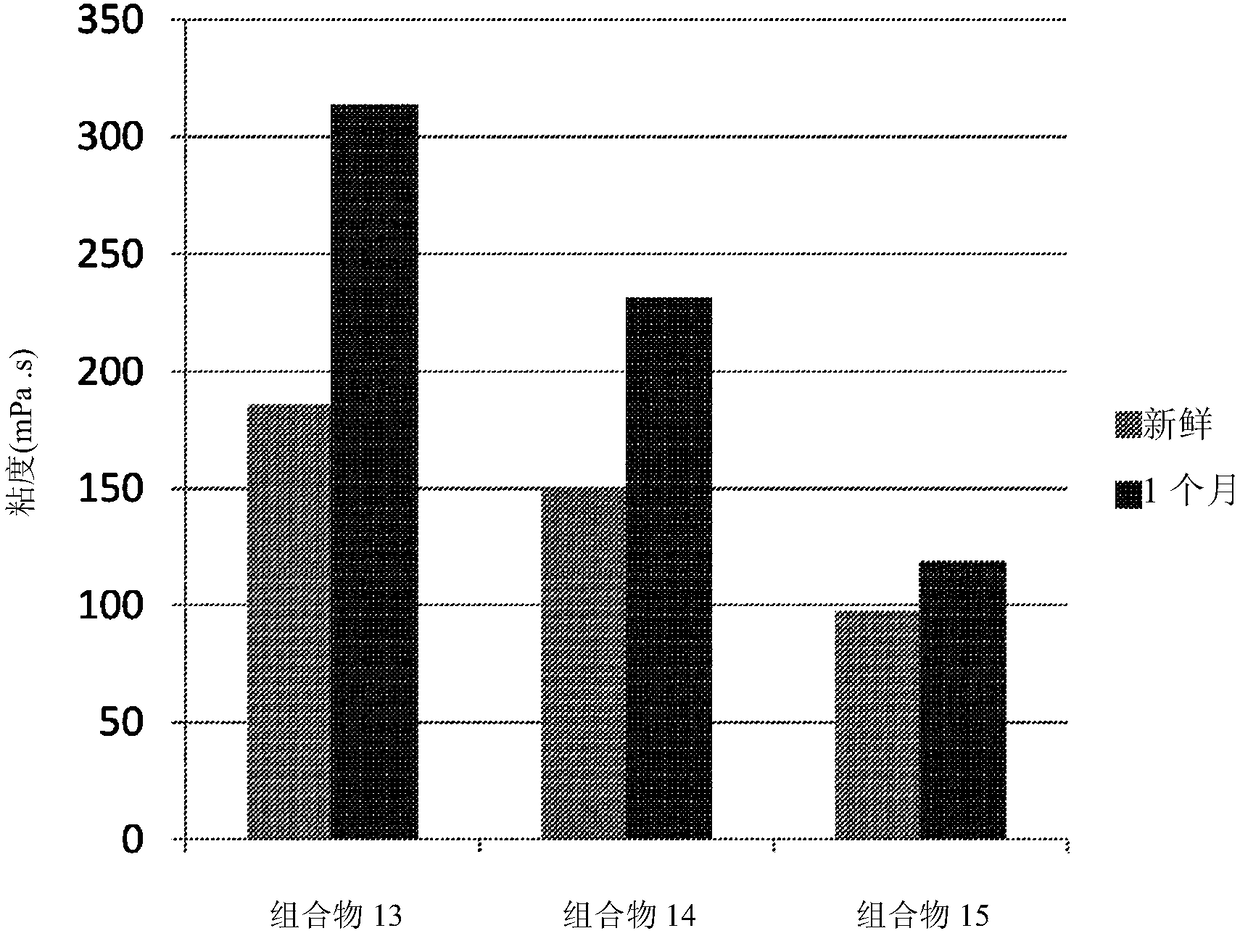

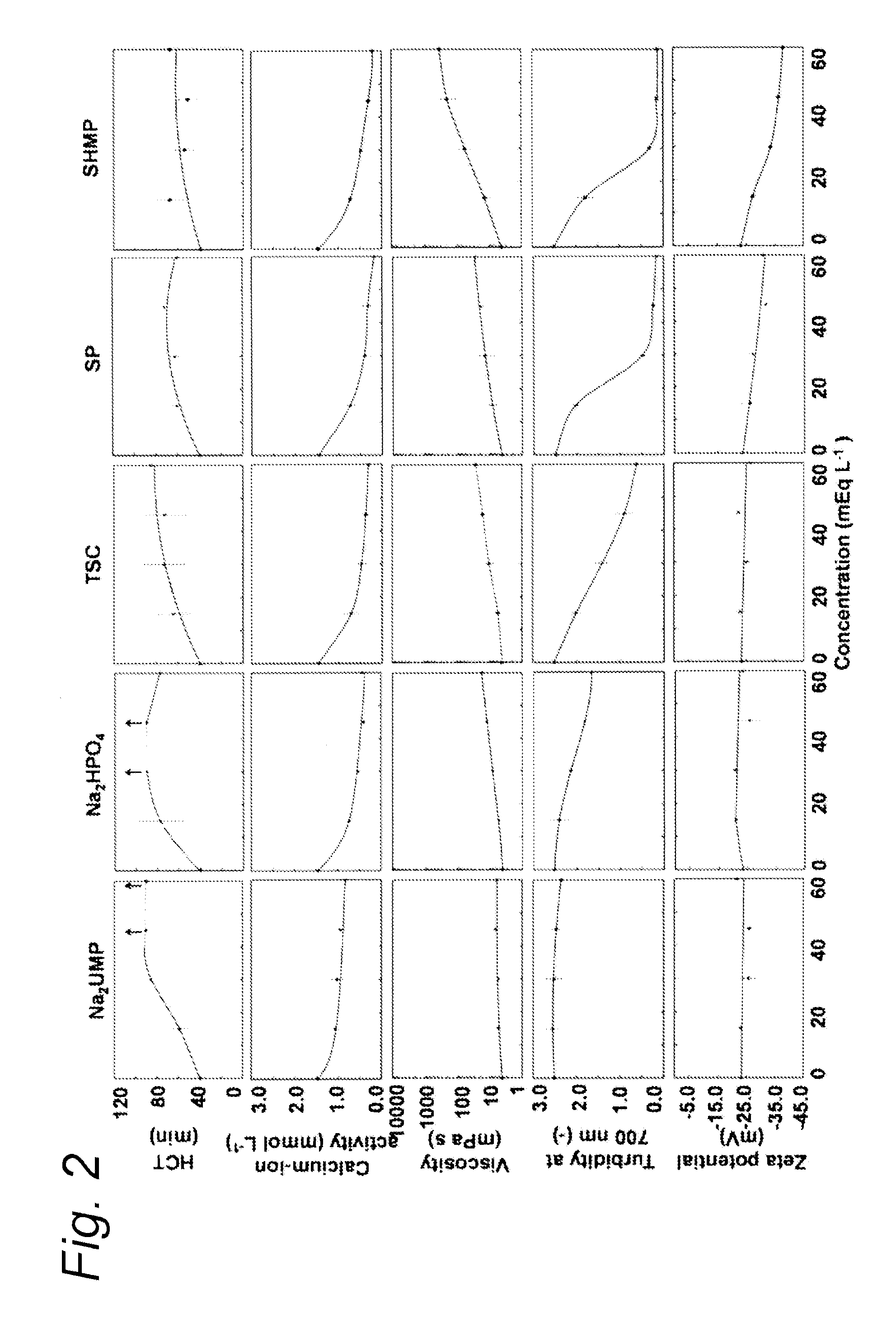

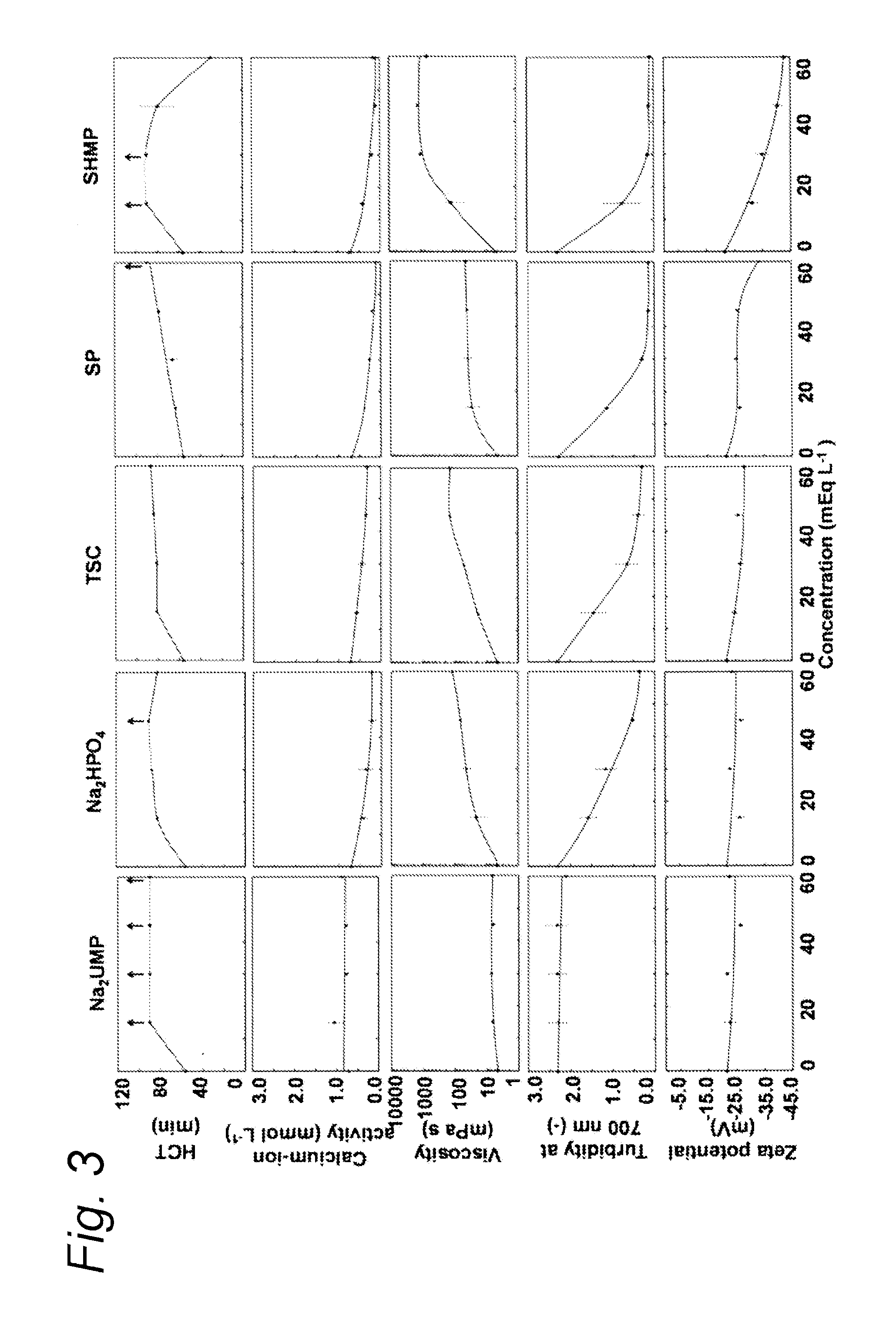

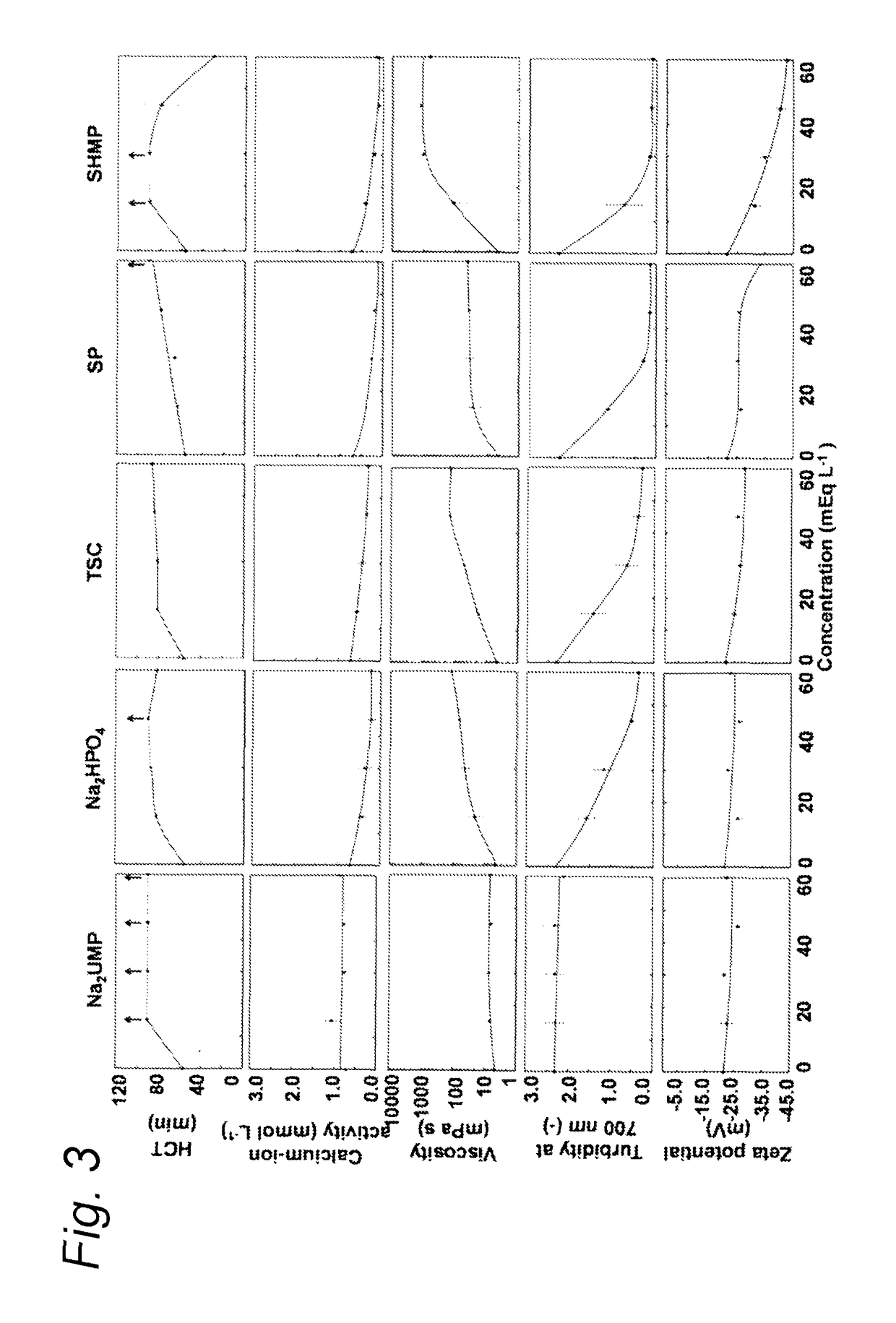

Controlling the texture of high-protein nutritional compositions comprising micellar casein

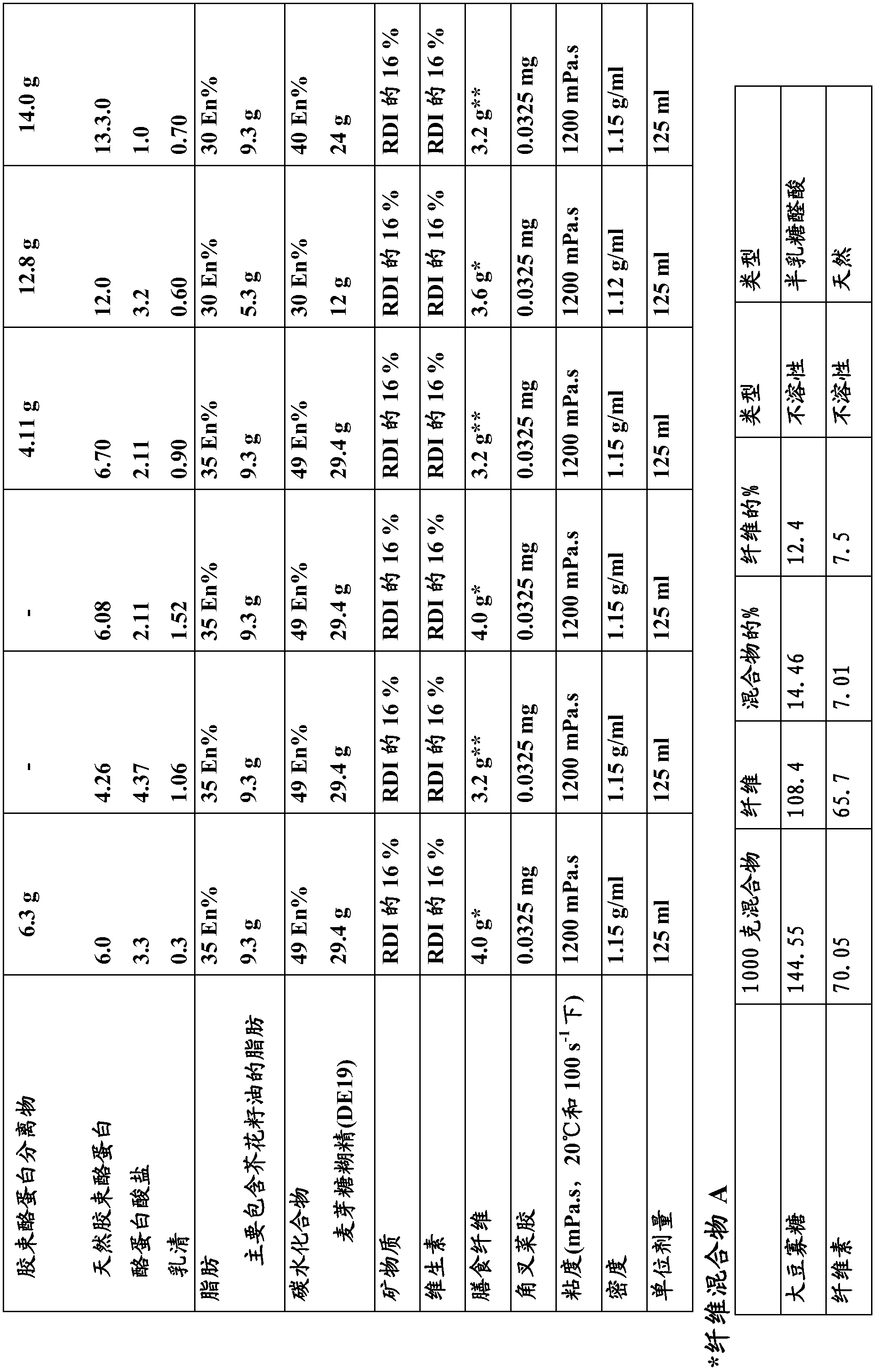

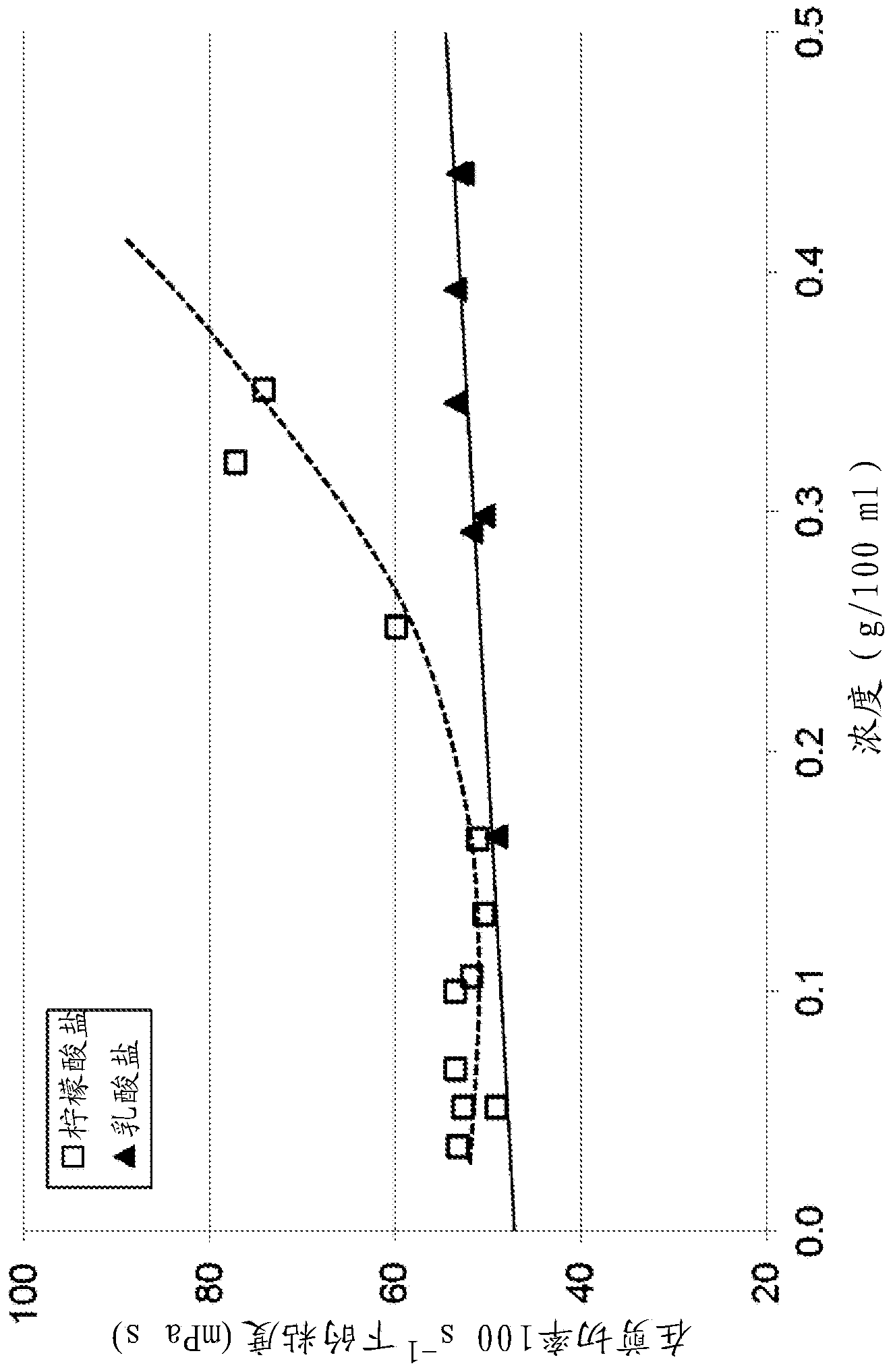

ActiveUS20130065824A1Low viscosityReduce consumptionPeptide/protein ingredientsMetabolism disorderHigh concentrationCitrate salt

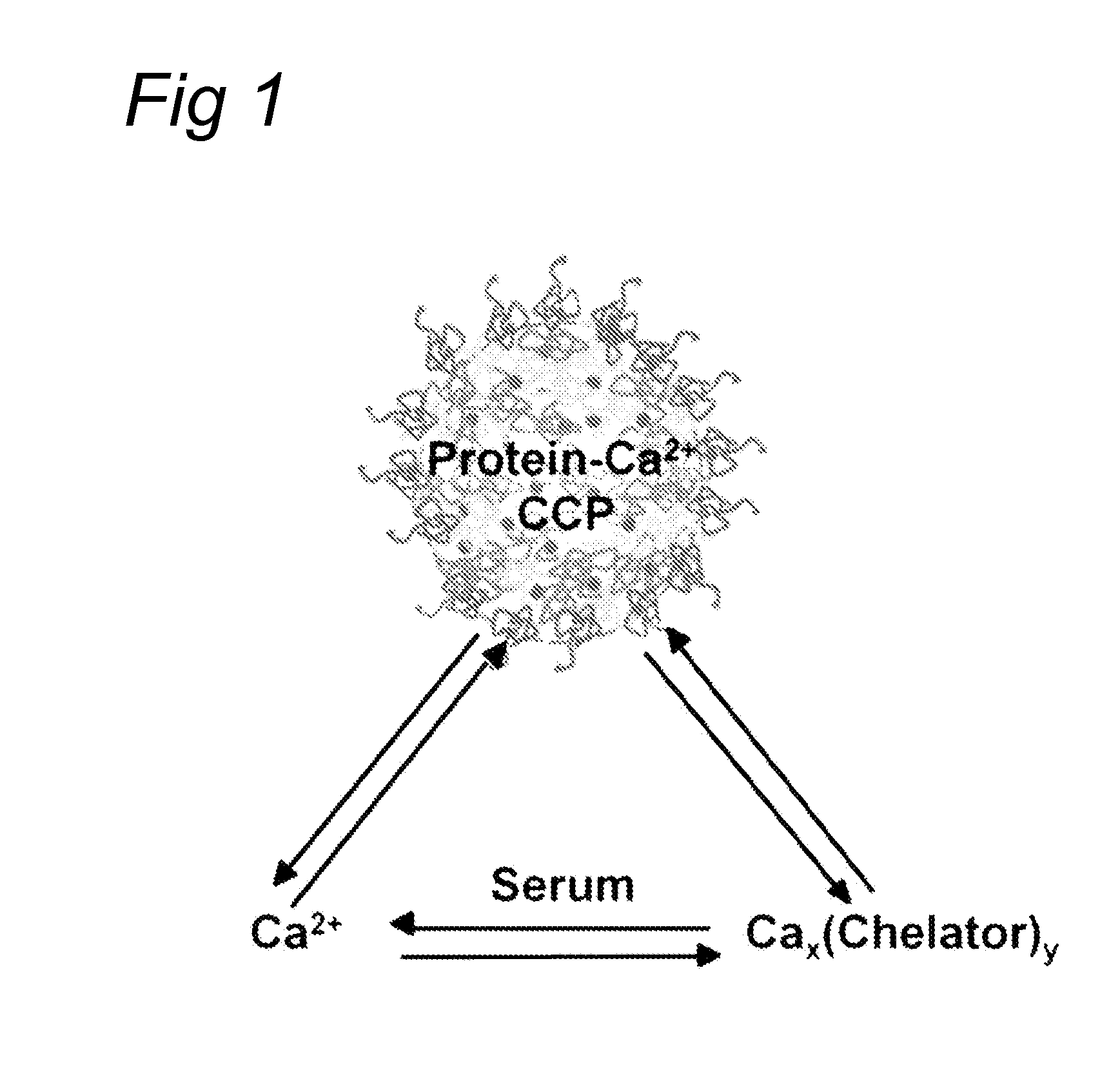

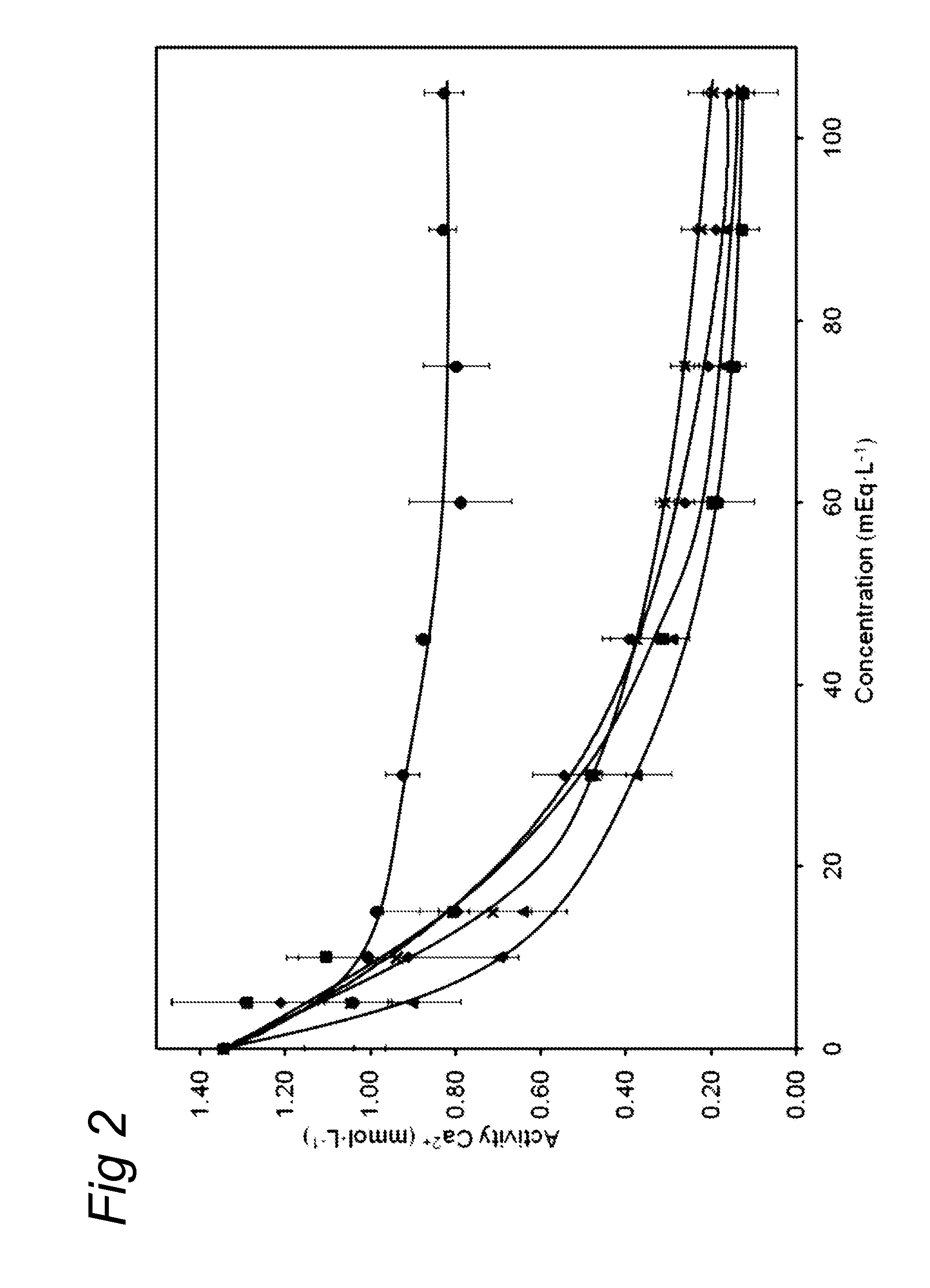

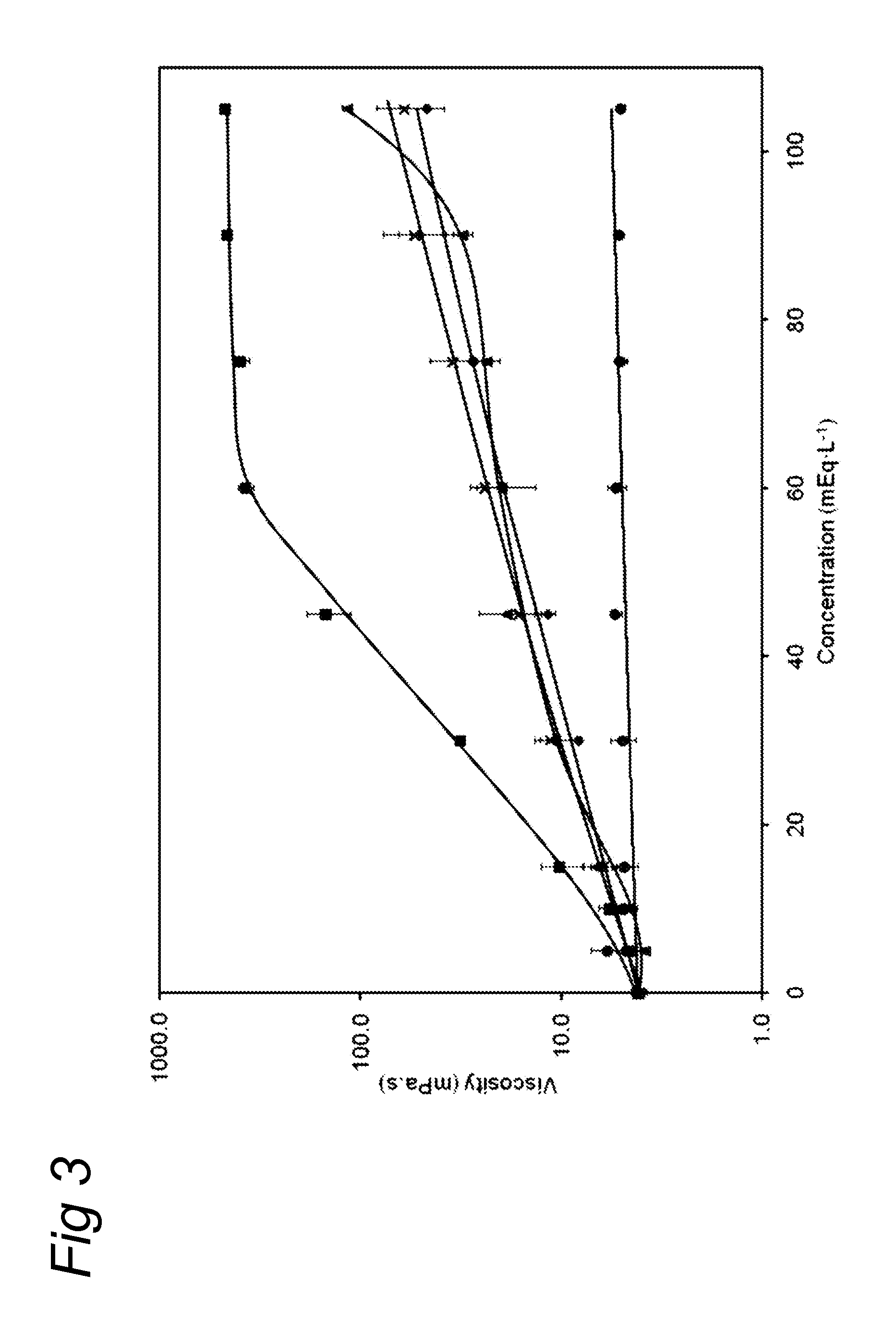

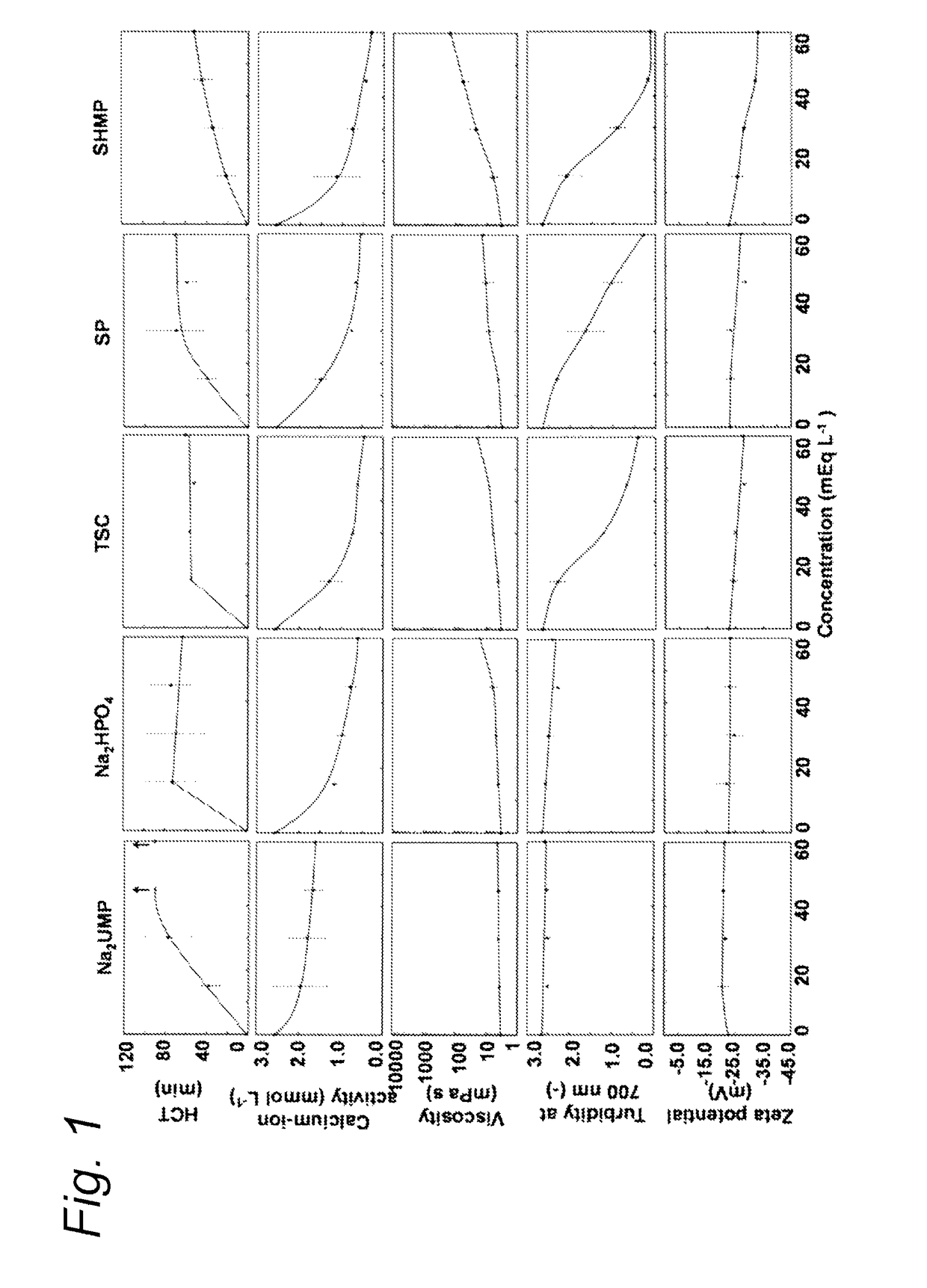

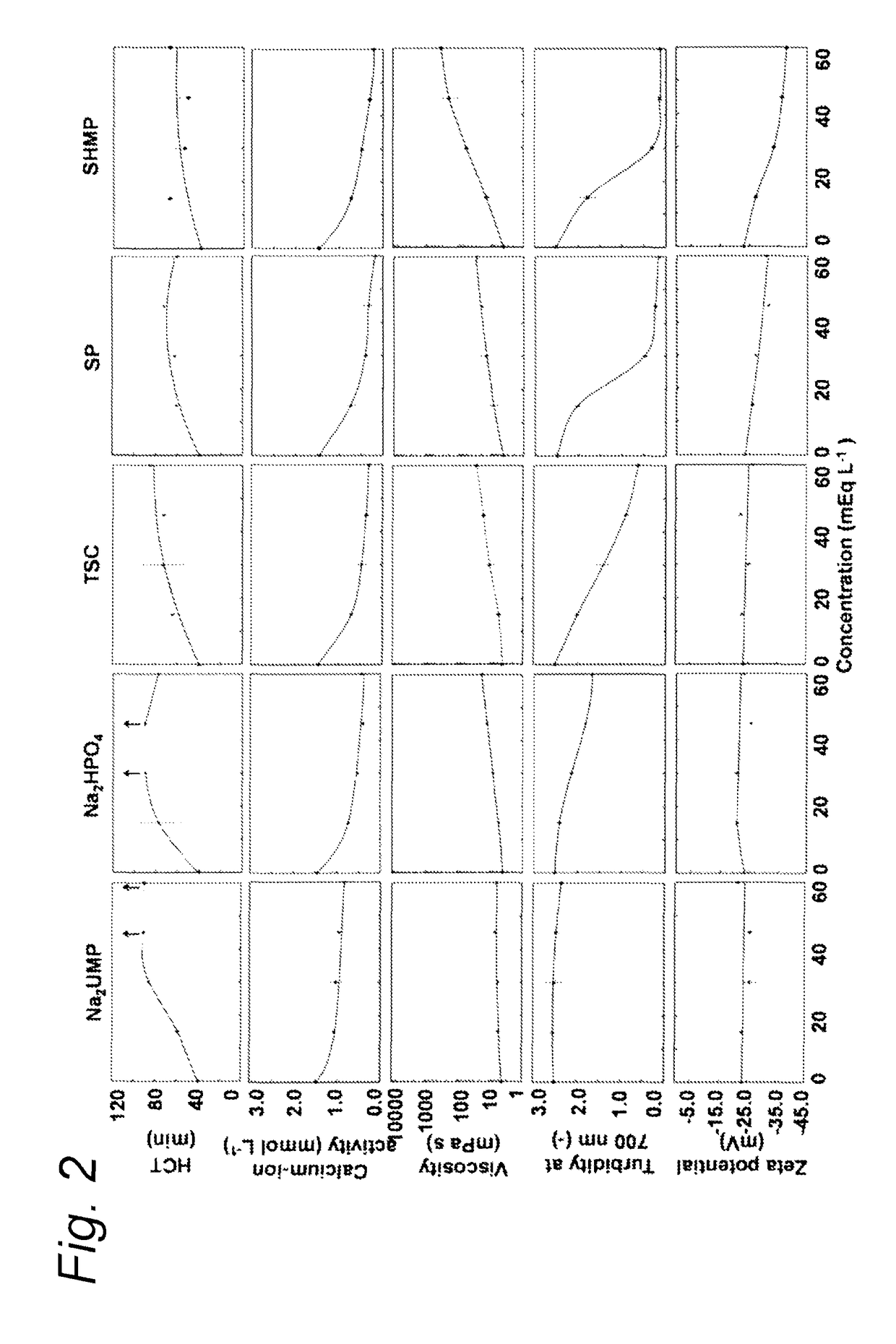

Medical dairy products are highly concentrated in proteins and minerals. Formulation of such products is challenging, since viscosities can easily increase during processing and storage. It was found that using one or more chelating agents selected from the group consisting of a phosphoric acid, citric acid, a soluble phosphate salt, a soluble citrate salt, or a mixture thereof, the viscosity and the transparency of an aqueous micellar casein composition, comprising 6 to 20 g / 100 ml of micellar casein and having a pH of about 6 to 8 could be controlled independently of each other. It was found that products become more viscous after addition of phytate, citrate, or orthophosphate, and that the viscosity depends on concentration and type of phosphate. Addition of hexametaphosphate leads to gel formation. In contrast, high concentrations of uridine monophosphate can be added without significantly affecting the viscosity.

Owner:NV NUTRICIA

Liquid high-fat protein composition

The present invention relates to nutritional compositions for use in people with a (partially) functional gastrointestinal tract who are unwilling and / or unable to consume sufficient amounts of conventional foods to meet their nutritional needs, such as being malnourished or at risk of developing malnutrition People who are in need of liquid oral nutrition. The shelf-stable liquid aqueous nutritional composition contains at least non-micellar casein, a substantial amount of fat, and optionally a heat stabilizing system.

Owner:NUTRICIA

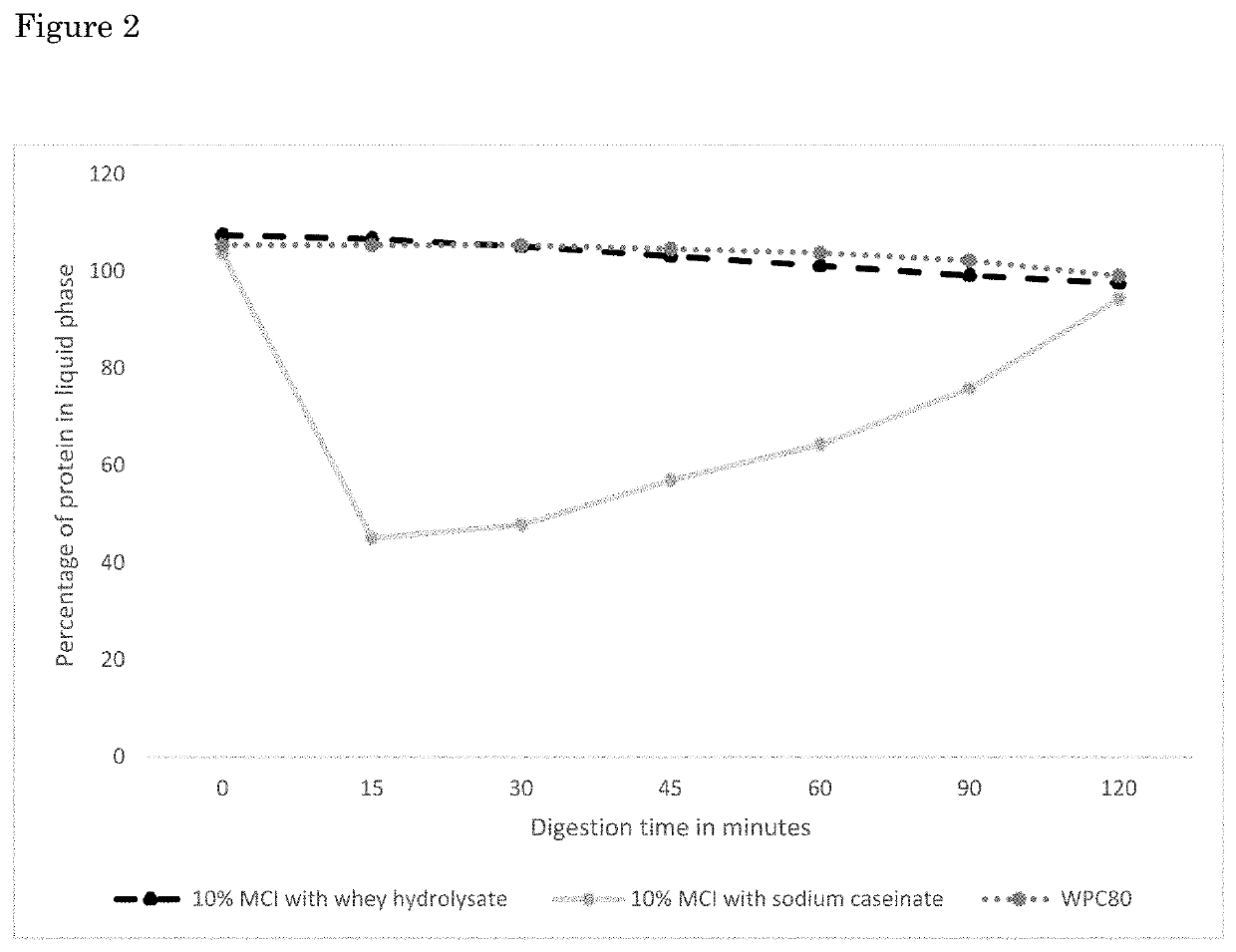

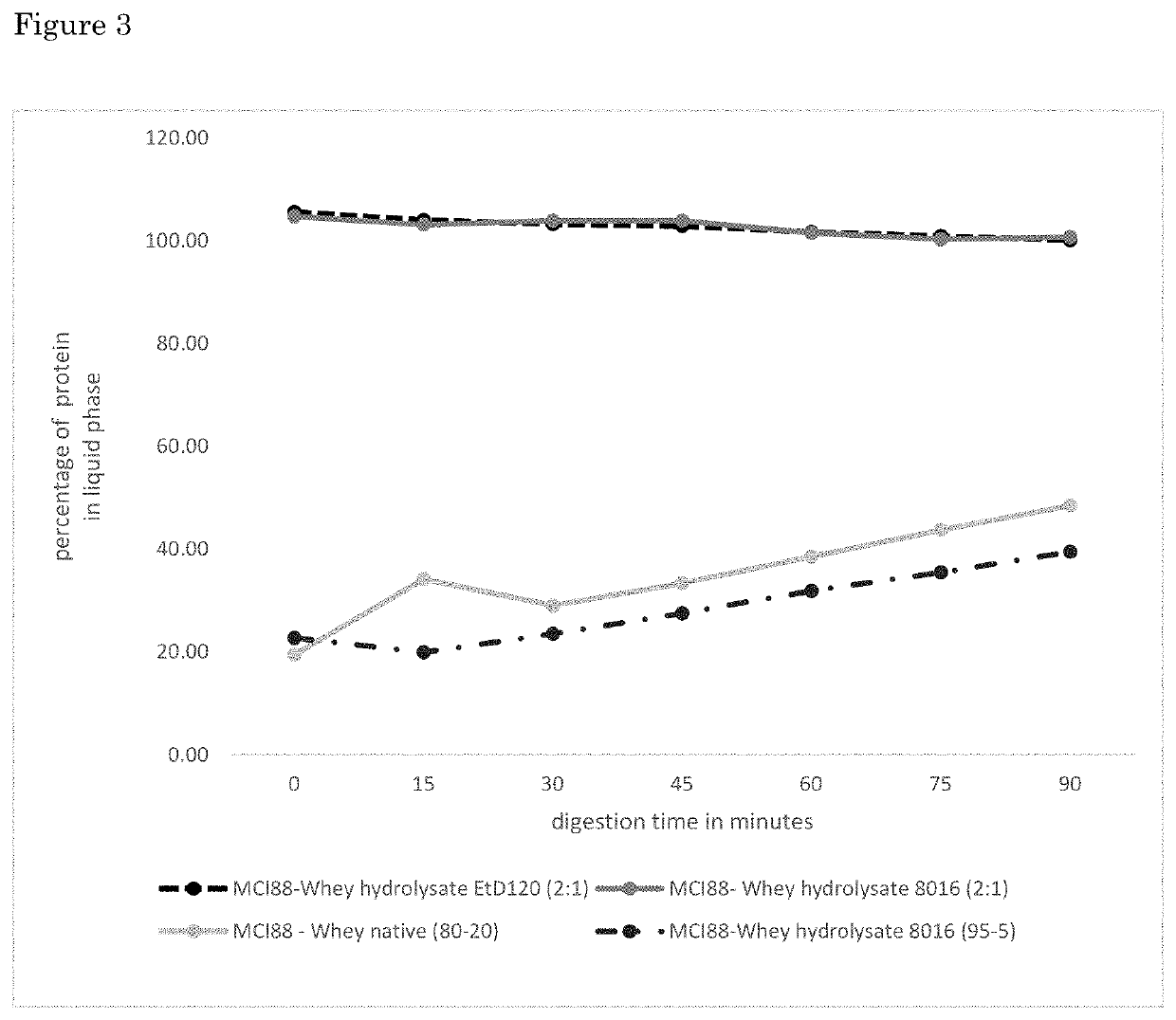

Liquid nutritional composition comprising micellar casein and hydrolysed whey protein

PendingCN108347953AHigh in proteinLow viscosityMilk preparationPeptide/protein ingredientsProtein compositionWhey protein

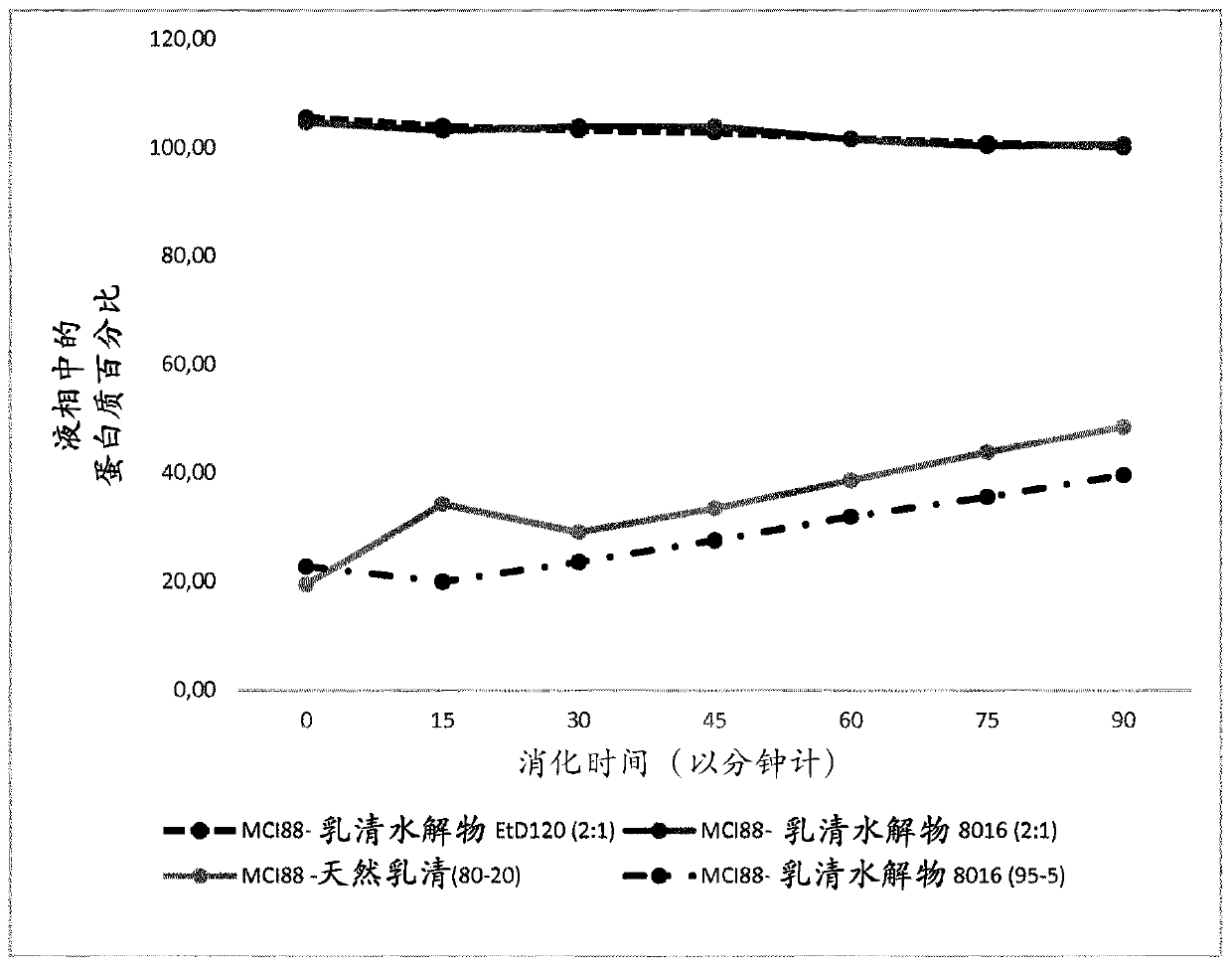

The present invention relates to a heat-treated liquid nutritional composition comprising 8-20 g of protein per 100 ml of the composition, wherein at least 40 wt.% of the protein is micellar casein and at least 10 wt.% of the protein is hydrolysed whey protein. The invention particularly relates to a heat-treated liquid nutritional composition comprising 8 - 20 g of protein per 100 ml of the composition, wherein at least 40 wt.% of the protein is micellar casein and at least 10 wt.% of the protein is hydrolysed whey protein, wherein the composition further comprises fat and / or carbohydrate, and wherein the composition has an energy density in the range of 1.5 to 3.5 kcal / ml. The invention also relates to a protein composition comprising at least 60 wt.% of protein, based on dry matter of the total composition, wherein at least 40 wt.% of the protein is micellar casein and at least 10 wt.% of the protein is hydrolysed whey protein, based on dry matter of the protein. In addition, the invention relates to methods for the manufacture of the nutritional composition and the protein composition according to the invention.

Owner:FRIESLANDCAMPINA NEDERLAND BV

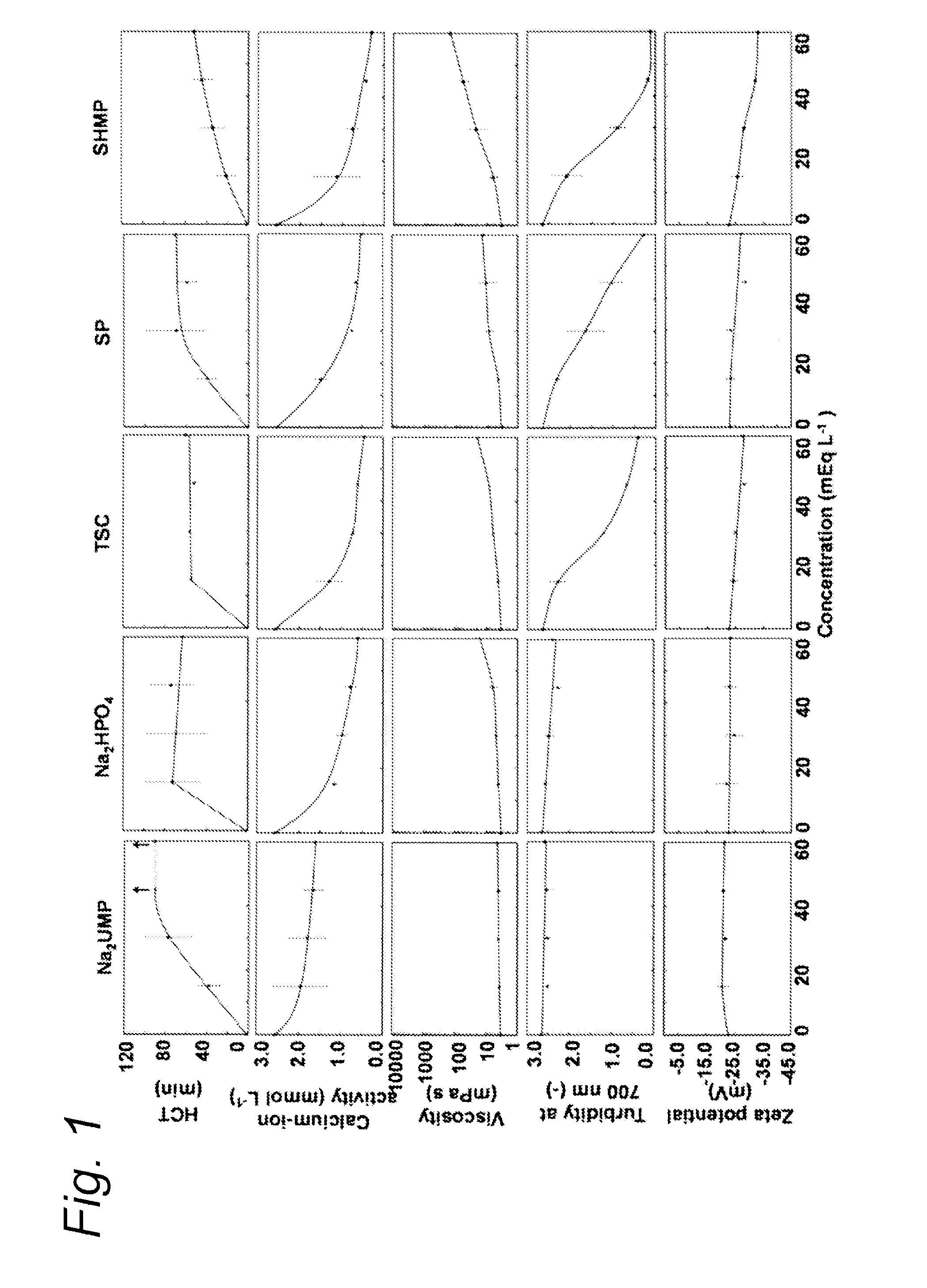

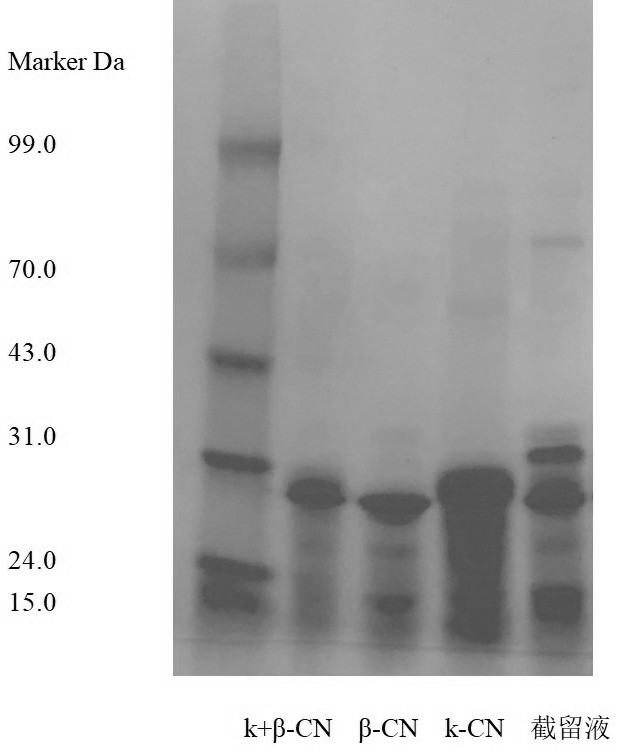

Use of a nucleotide for improving the heat stability of an aqueous micellar casein composition

ActiveUS20140135257A1Improve thermal stabilityPeptide/protein ingredientsFood ingredient functionsMicellar caseinNucleotide

The invention relates to the use of one or more nucleotides for improving the heat stability of an aqueous micellar casein composition comprising 6 to 20 g per 100 ml of micellar casein, and having a pH of about 6 to 8. The invention also relates to heat-treated liquid nutritional compositions comprising 6 to 20 g, preferably 9-20 g, of protein per 100 ml of the composition and having a pH of about 6 to 8, in which all or a major part of said protein comprises micellar casein, further comprising one or more nucleotides.

Owner:NUTRICIA

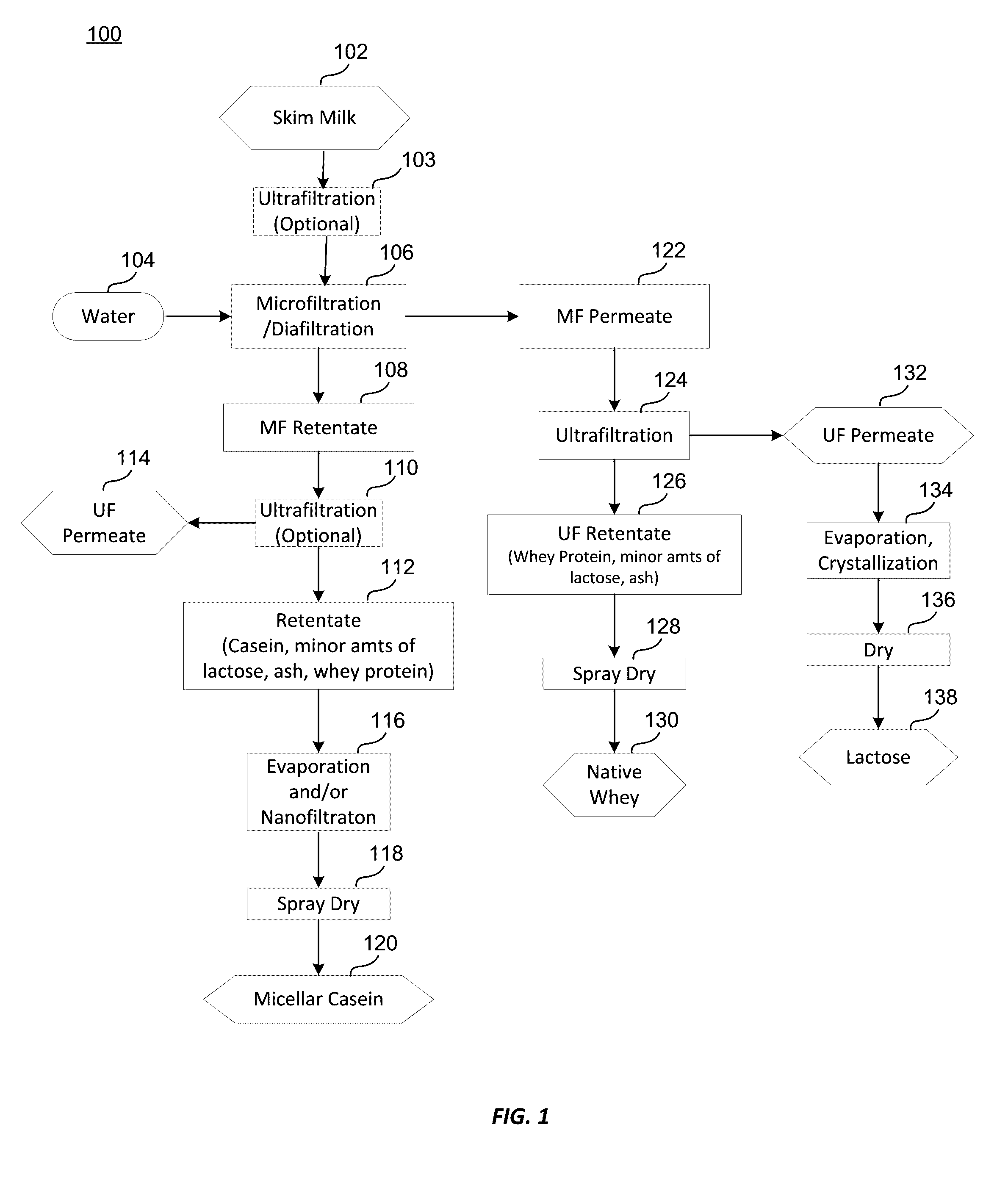

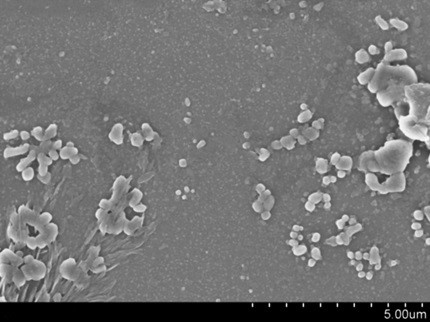

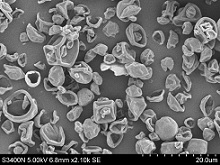

Functional digestible micelle-state casein powder and preparation method thereof

ActiveCN113057250AIncrease negative chargeStable structureChemical industryProtein composition from milkBiotechnologyMicellar casein

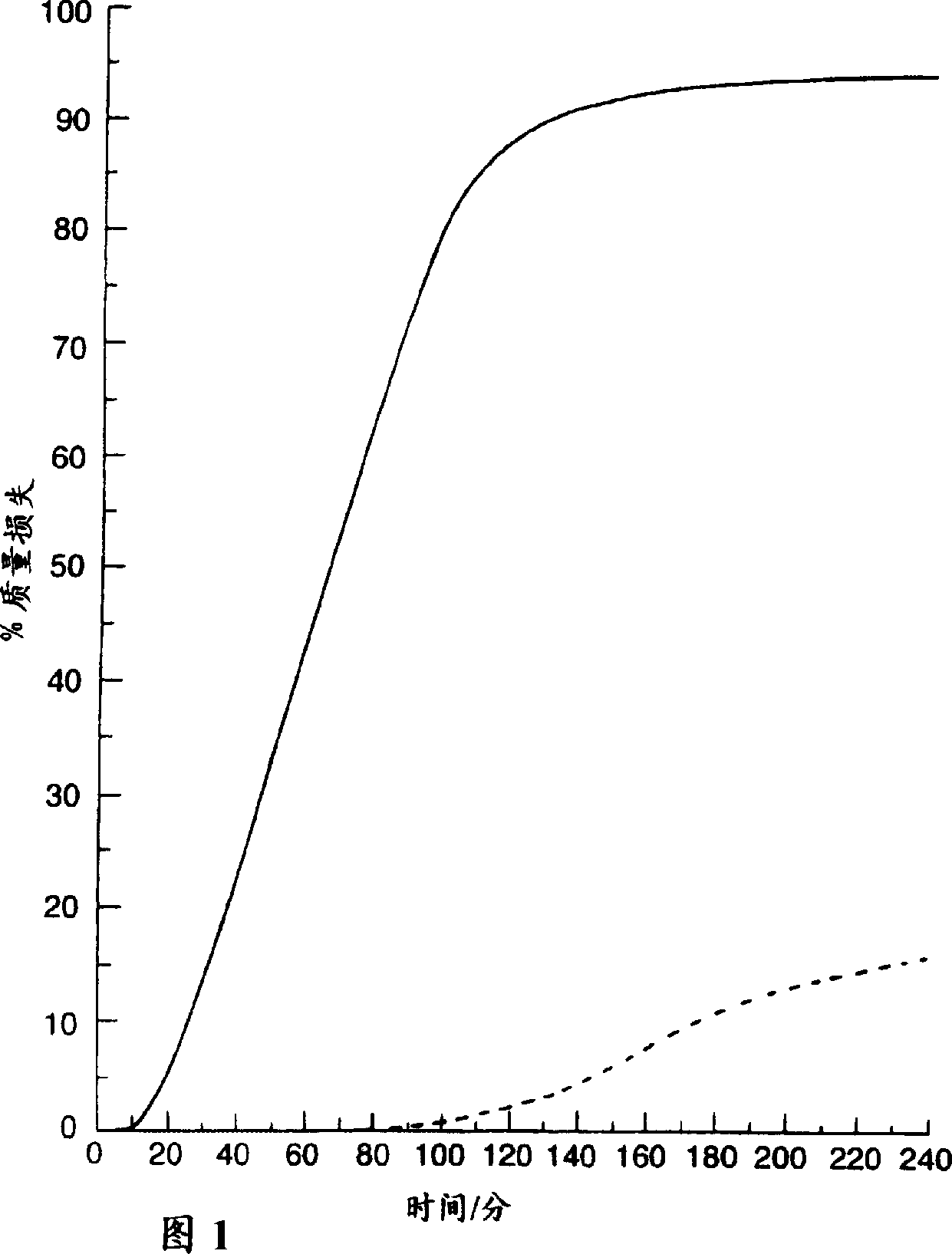

The invention discloses functional digestible micelle-state casein powder and a preparation method thereof. The preparation method comprises the following steps: pretreating skimmed milk, preparing micelle-state casein, preparing a compound of functional molecules and the micelle-state casein, and drying the compound, so as to obtain the functional micelle-state casein powder which is relatively good in compressibility, rapid in rehydration and relatively good in solubility and digestibility. The dissolvability and digestibility of the micelle-state casein product can be remarkably improved, so that the micelle-state casein product can be more easily digested into small molecule peptide in an organism. In addition, micellar casein is taken as a carrier, so that loading, delivery and slow release of the functional micromolecules are realized, bioavailability of the functional micromolecules is improved, and health-care effects of the casein and the functional micromolecules are brought into full play. The functional micelle-state casein powder prepared by the preparation method disclosed by the invention has wide application and wide market prospect no matter being used as a health-care product or a raw and auxiliary material in food and medicine industries.

Owner:GANSU AGRI UNIV

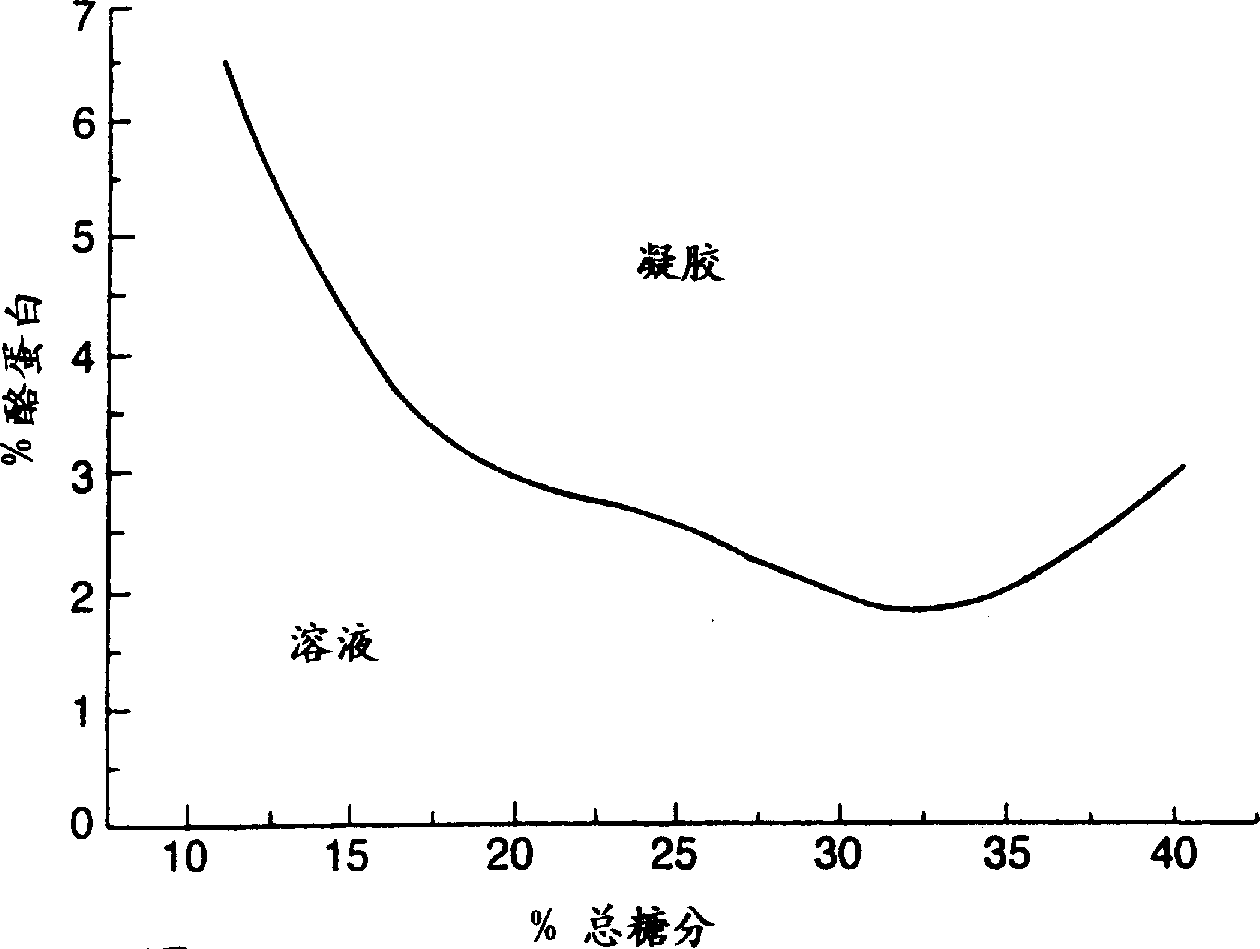

Method for the preparation of a food stuff

A process for the preparation of an ice confection having an aqueous phase and a fat phase, wherein the ice confection is subjected to an ultra high pressure treatment, the ice confection comprising in the aqueous phase at least 1 wt.% micellar casein and sufficient total sugars such that a protein gel is formed on application of the ultra high pressure, providing that if micellar casein is present in the aqueous phase at less than 2 wt.%, the ice confection composition includes a stabiliser.

Owner:UNILEVER NV

Method for the preparation of a liquid enteral nutritional composition comprising micellar casein

ActiveUS20150351437A1High in proteinReduce the amount of solutionFood preparationMicellar caseinNutritional composition

The invention relates to a method for preparing a shelf-stable liquid enteral composition for providing nutrition, either as a supplement, or as a complete nutrition, comprising a high amount of micellar casein, comprising dissolving a dry blend of micellar casein and digestible carbohydrate.

Owner:NV NUTRICIA

Energy gum for recovering physical fitness after movement and preparation method of energy gum

InactiveCN108244652AEasy to synthesizeSynthesis blockInorganic compound food ingredientsNatural extract food ingredientsComposite electrolyteHydrolysate

The invention provides energy gum for recovering physical fitness after movement and a preparation method of the energy gum. The functional components of the energy gum consist of pure water, cane sugar, levulose, maltodextrin, L-leucine, L-isoleucine, L-valine, whey protein hydrolysates, separated whey protein, micellar casein, a red jujube extract, calcium beta-hydroxy-beta-methylbutyrate, concentrated apple juice, composite vitamins and composite electrolyte. The capacity of organisms for resisting oxygen deficit and quickly decomposing lactic acids can be effectively strengthened, the weariness time is shortened, the recovery of physical fitness can be accelerated, and finally the movement capacity is improved.

Owner:诺和生物技术(天津)有限公司

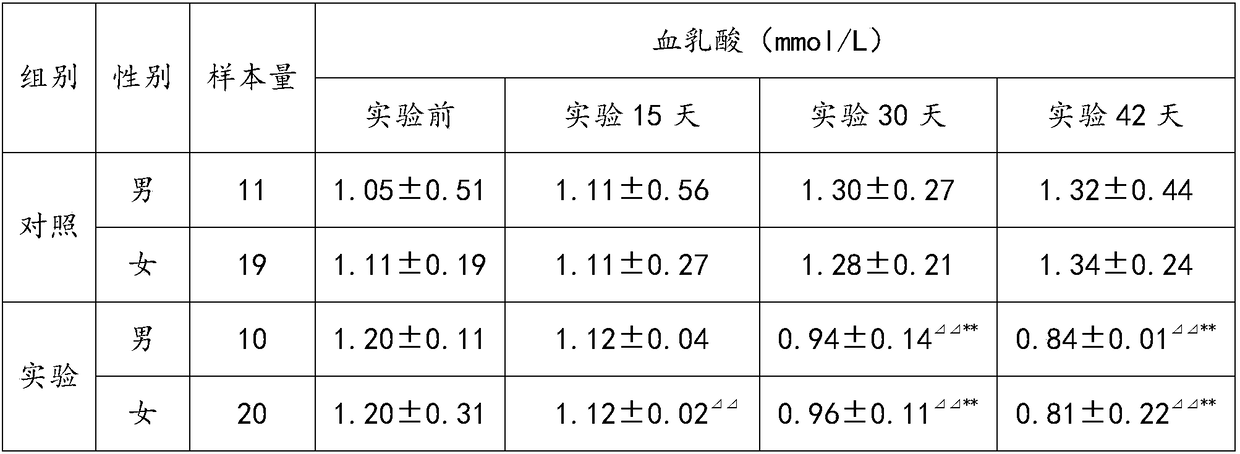

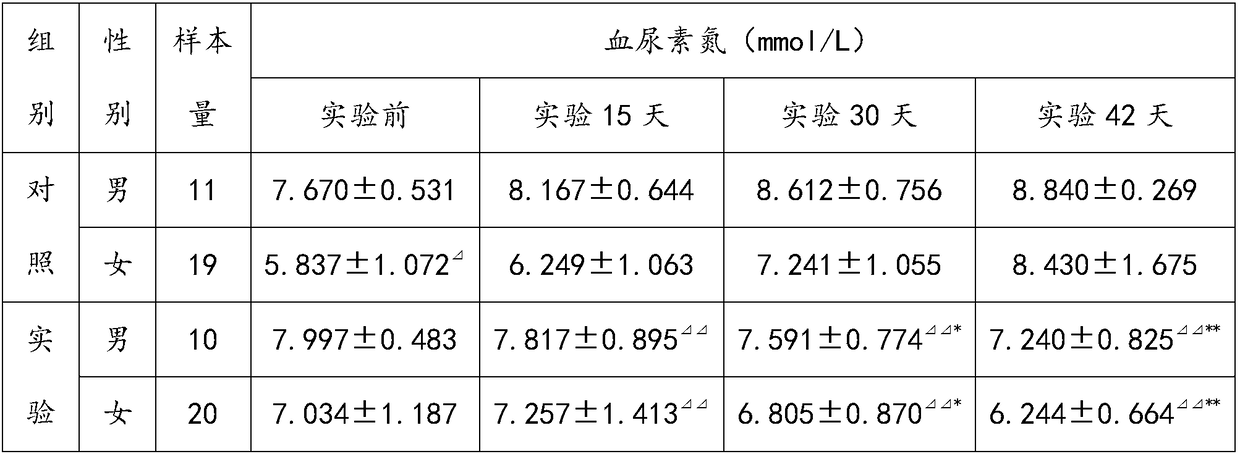

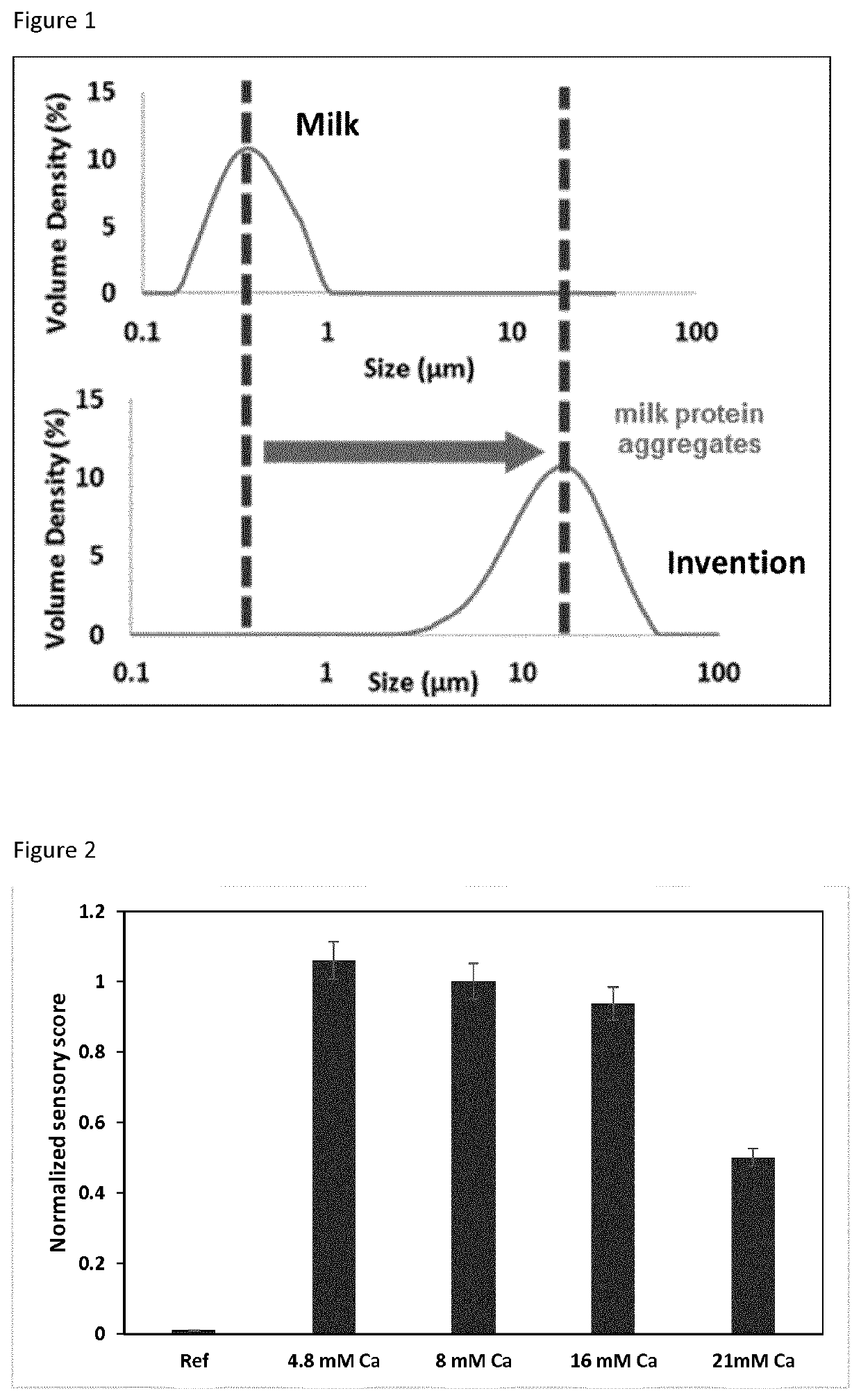

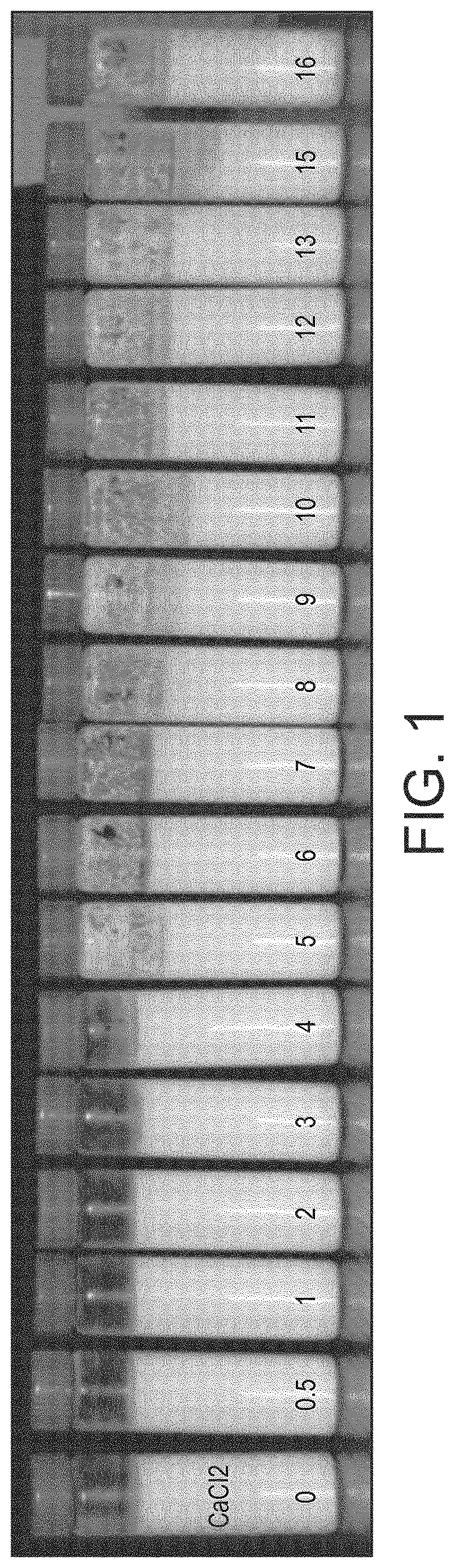

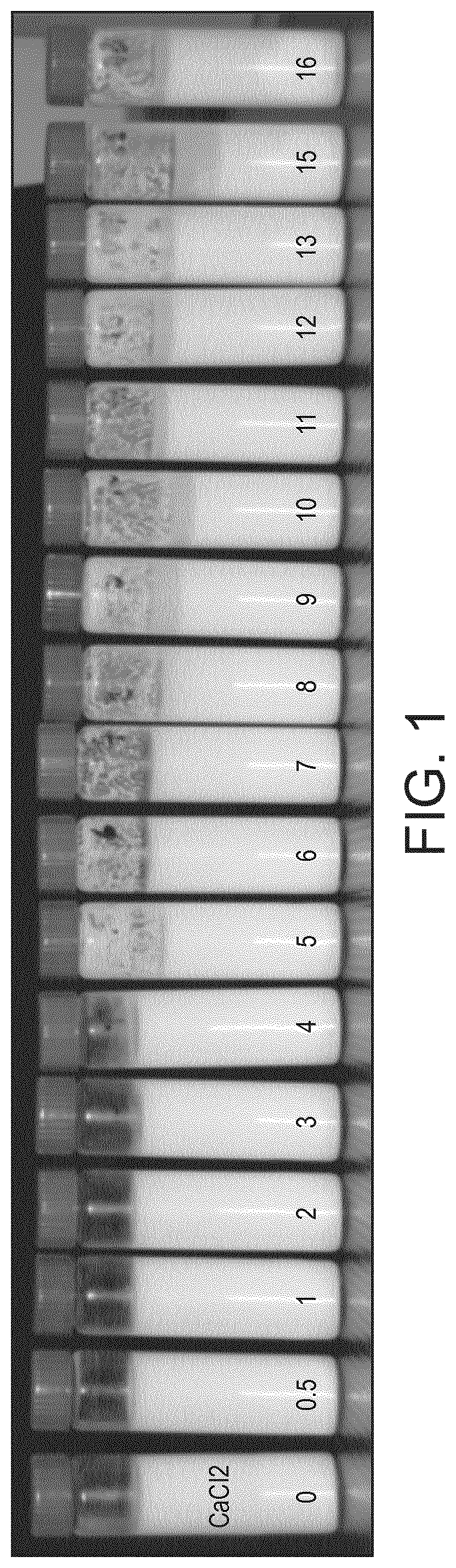

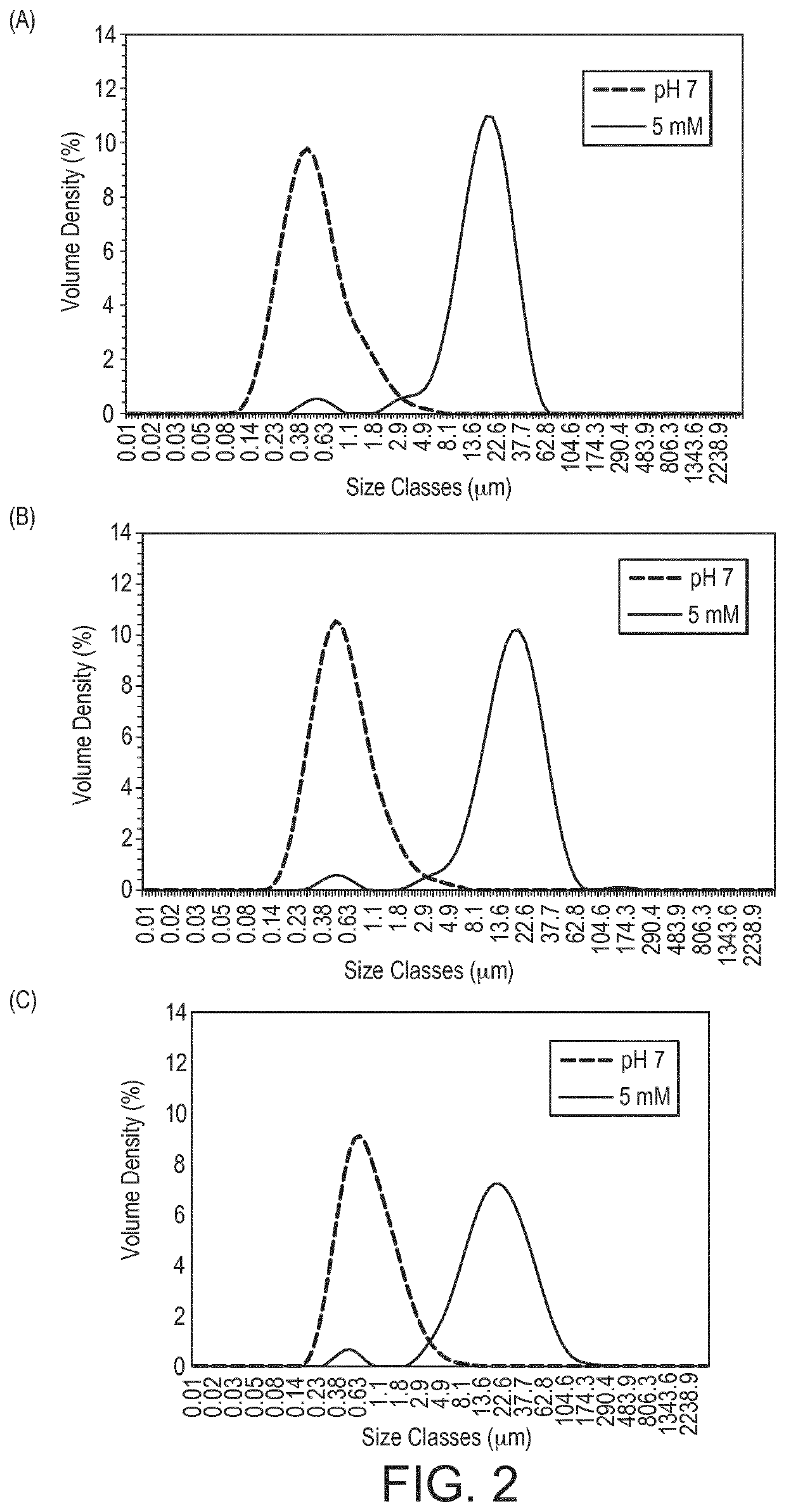

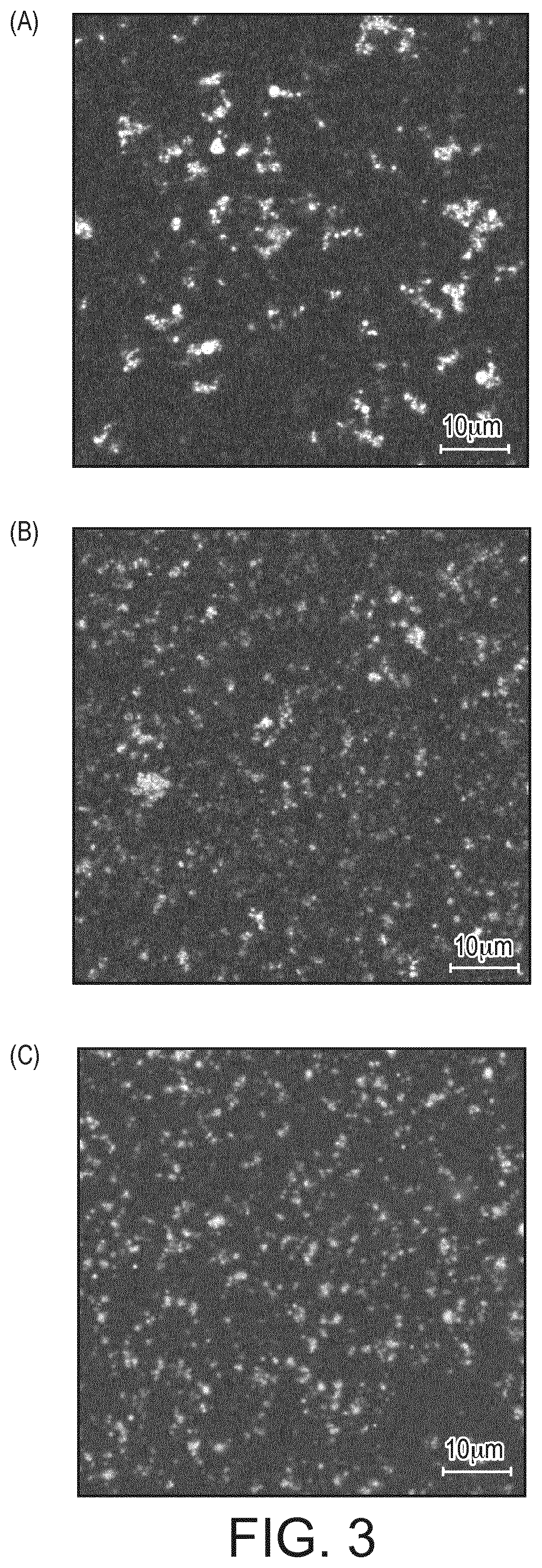

A beverage product with free divalent cations protein aggregation and a method producing thereof

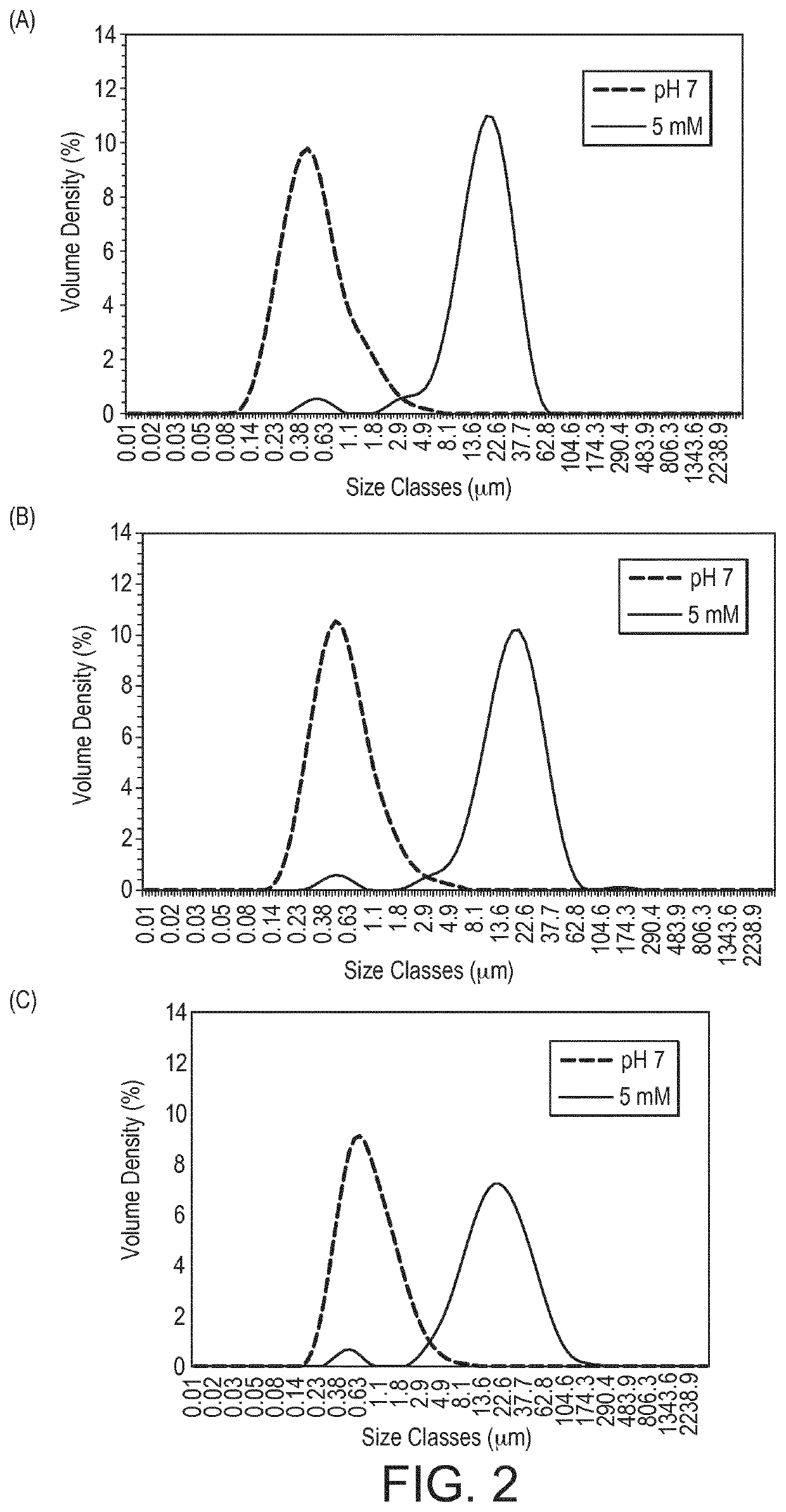

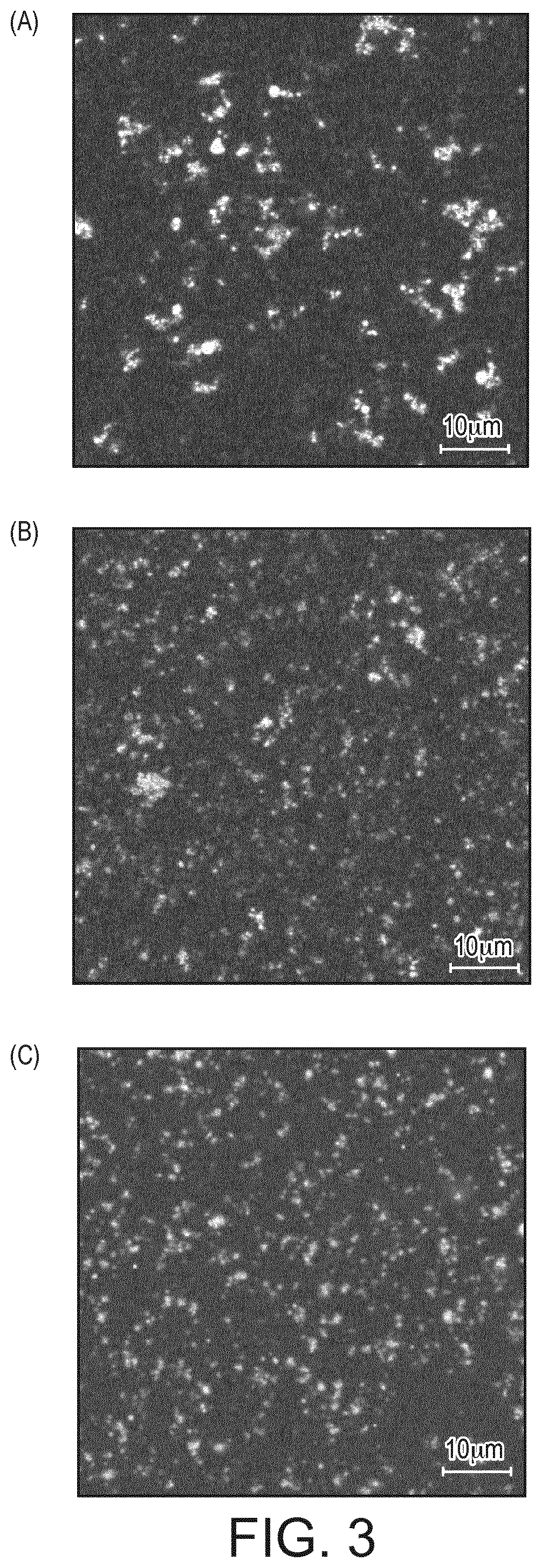

ActiveUS20190364917A1Improve textureImprove mouthfeelMilk preparationMilk preservationMean diameterAdditive ingredient

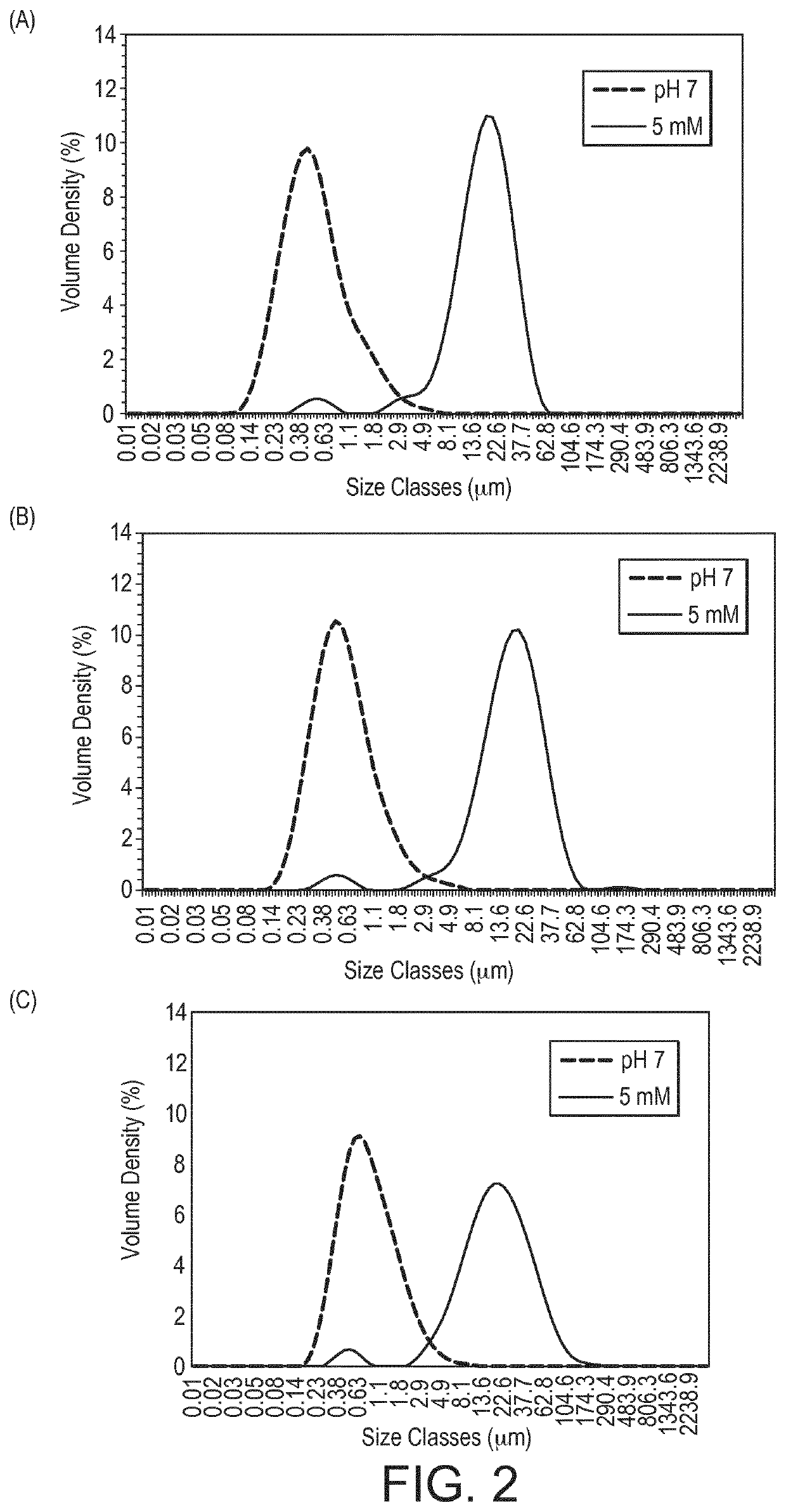

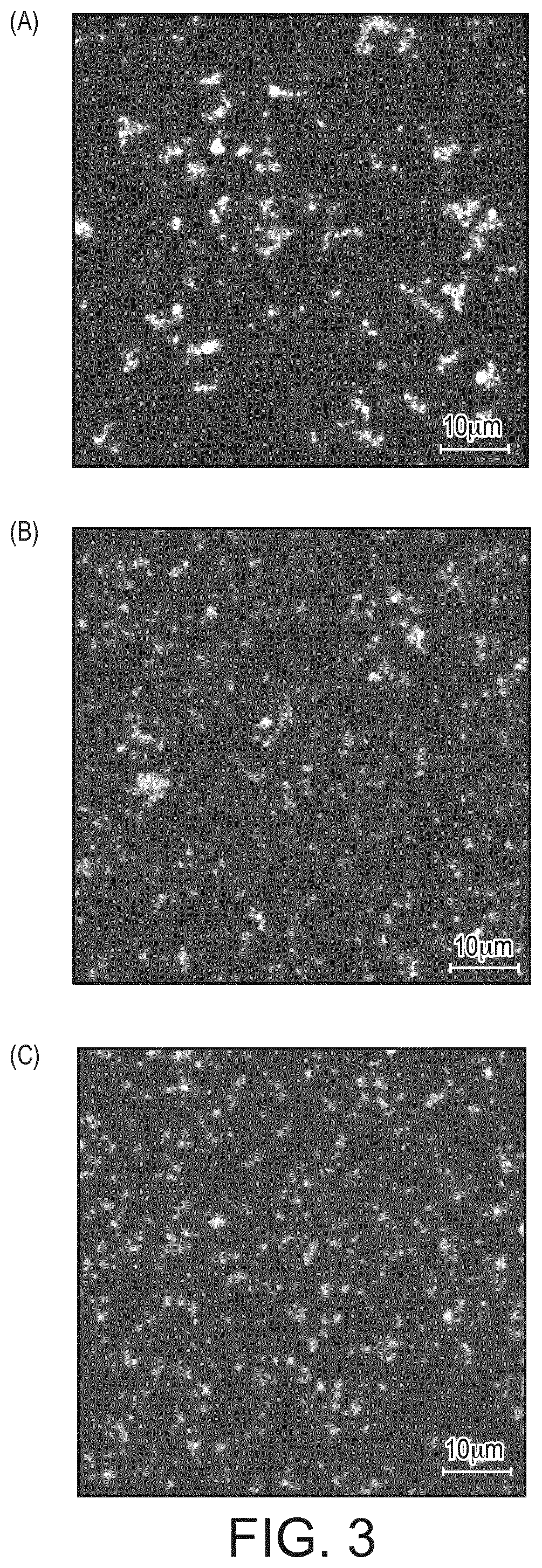

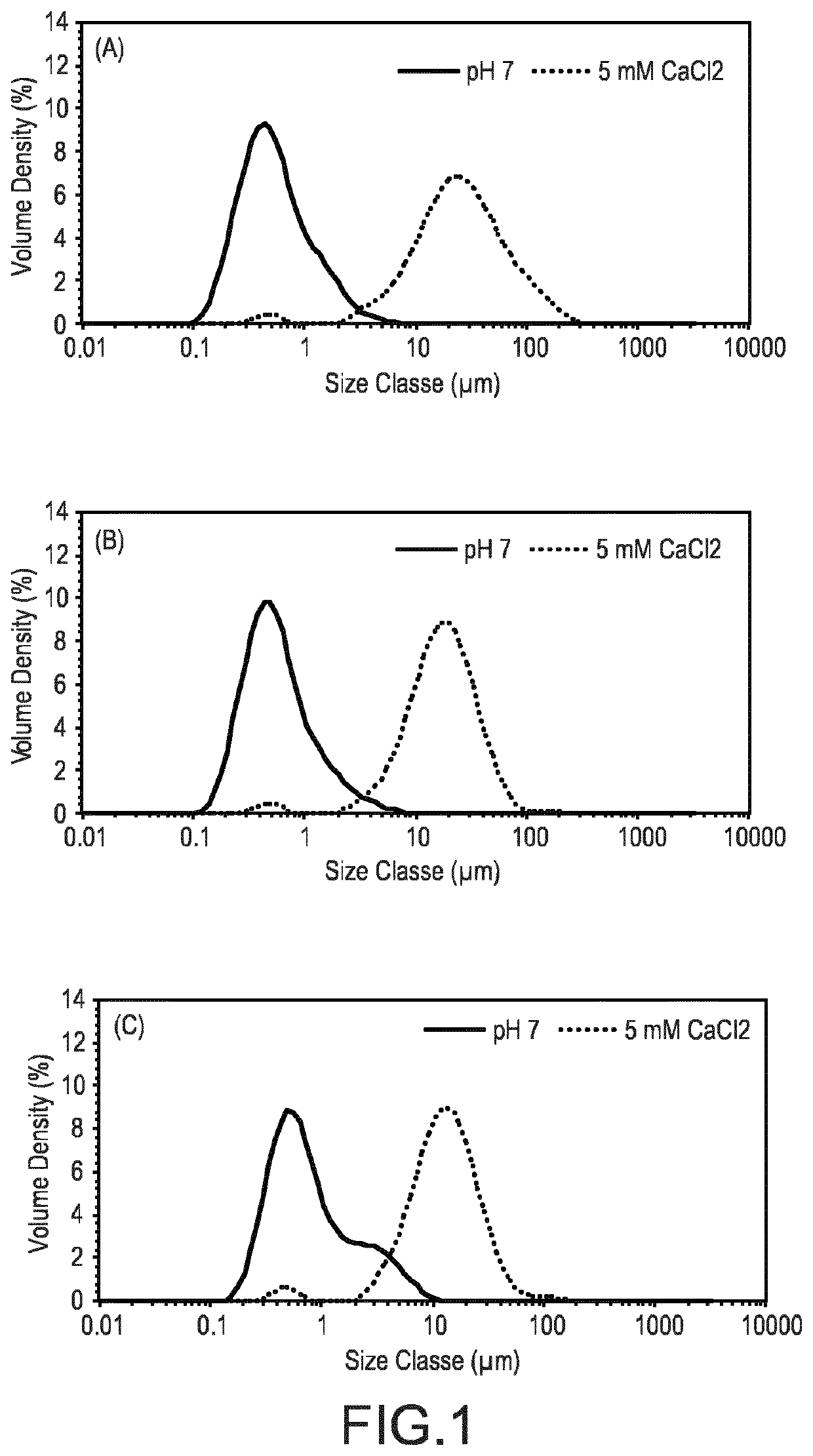

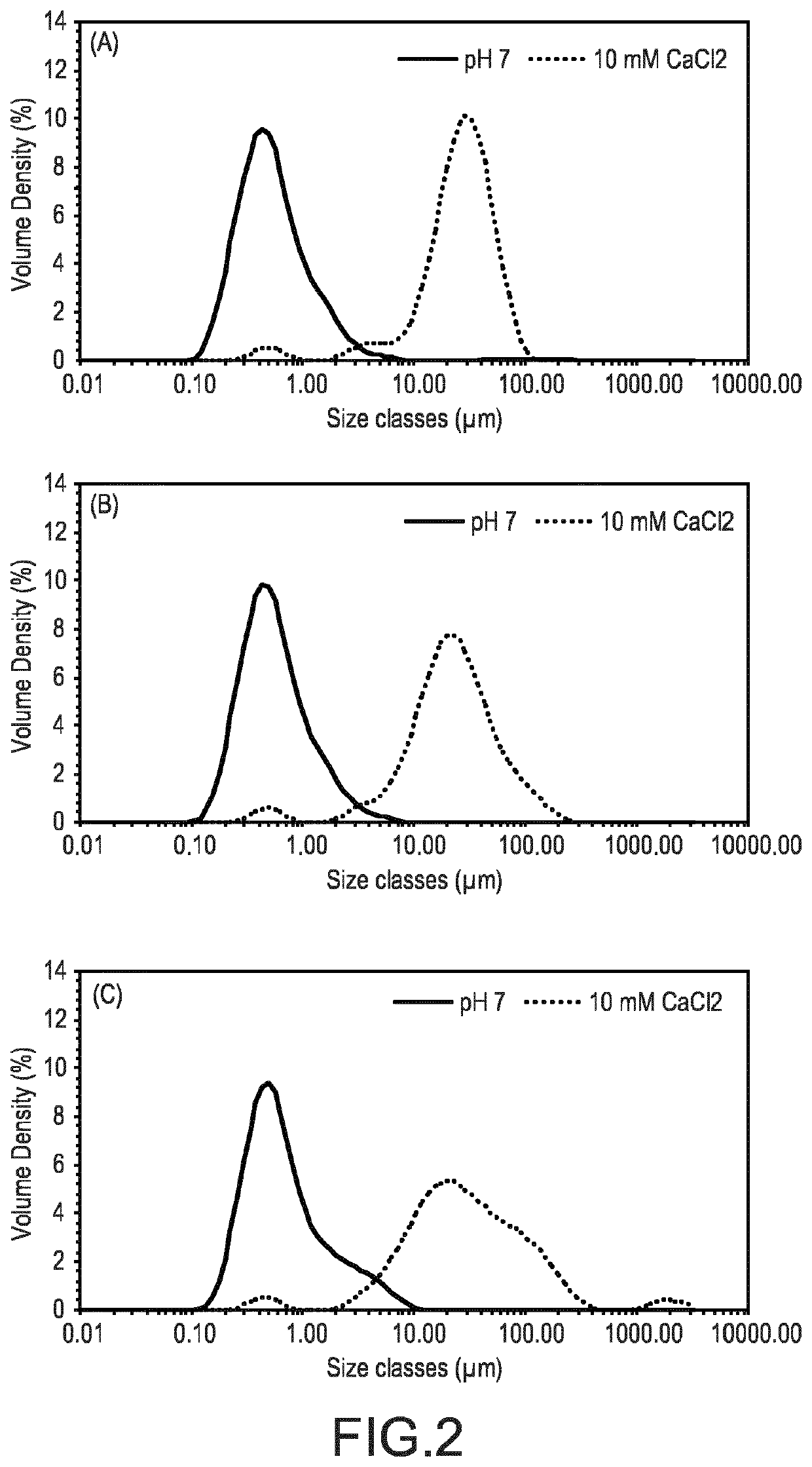

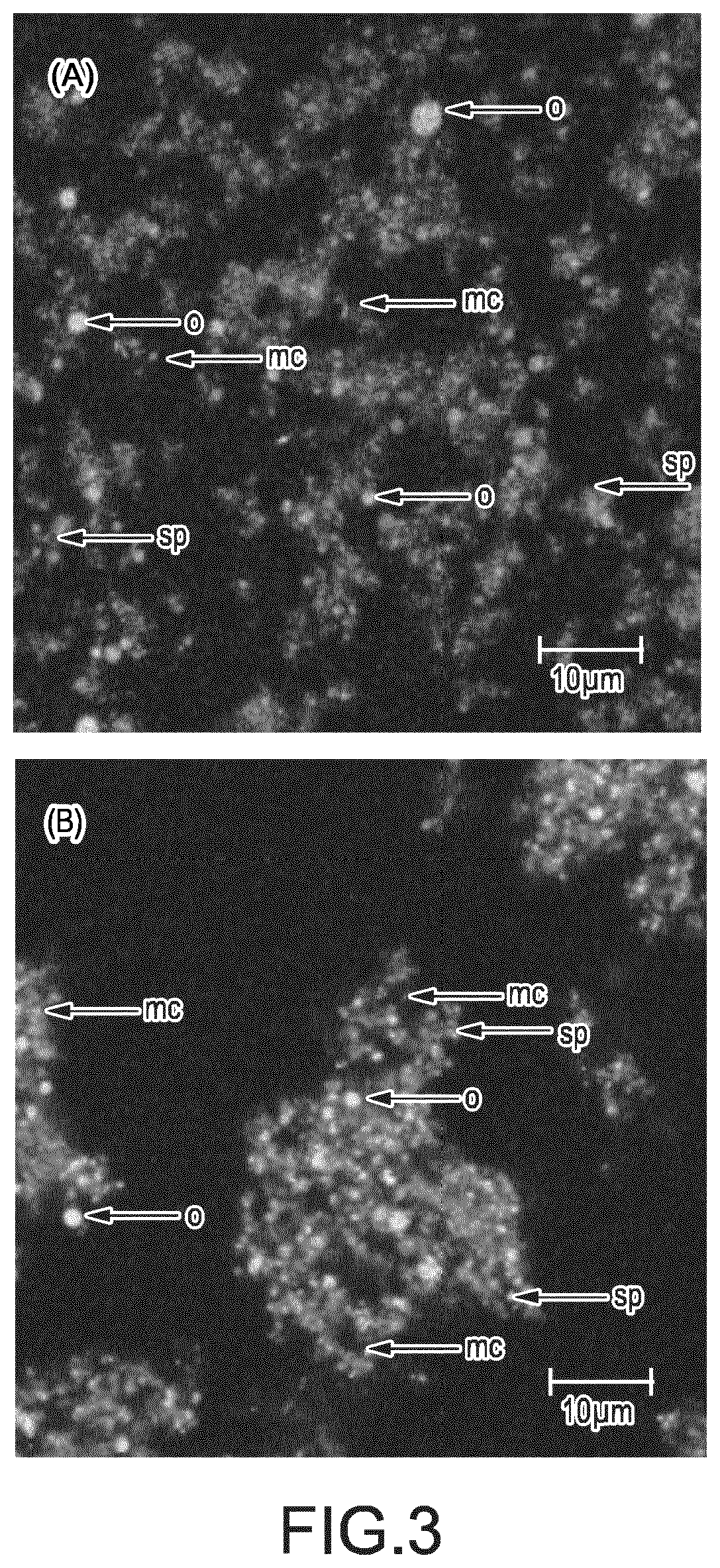

The invention relates to a method of producing a shelf stable ready-to-drink beverage product, comprising the steps of: providing an ingredient composition comprising micellar caseins and whey protein, having a total protein concentration of 1.5-8 wt. %, and wherein the composition has a casein to whey protein ratio of 90 / 10-60 / 40, adding divalent cations to provide a concentration of 3-20 mM free divalent cations in the ingredient composition, and 0.025-0.3 wt % of a stabilizing system comprising hydrocolloids, and subsequently heat treating the ingredient composition at ultra high temperature (UHT) at 135-150° C. for 3-30 s to form agglomerated proteins comprising casein and beta-lactoglobulin from the whey protein, the agglomerates having a size of 5-30 microns mean diameter D(4,3) as measured by laser diffraction. The invention also relates to a shelf stable ready-to-drink beverage product comprising aggregated proteins comprising micellar caseins and whey protein aggregates, wherein the product has a pH of 6.6-7.2, 1.5-8.0 wt. % milk proteins, a casein to whey protein ratio of 90 / 10-60 / 40, and a concentration of 3-20 mM divalent cations, and the aggregates are of 5-30 microns mean diameter D(4,3) as measured by laser diffraction.

Owner:SOC DES PROD NESTLE SA

Micellar casein for coffee creamers and other dairy products

Nutritional compositions are described that include a casein compound that includes micellar casein, a vegetable oil, a sweetener, and an acidity regulator, among other ingredients. The nutritional compositions may be used as beverage creamers, such as coffee creamers. Also described are methods of making nutritional compounds that include micellar casein.

Owner:LEPRINO FOODS

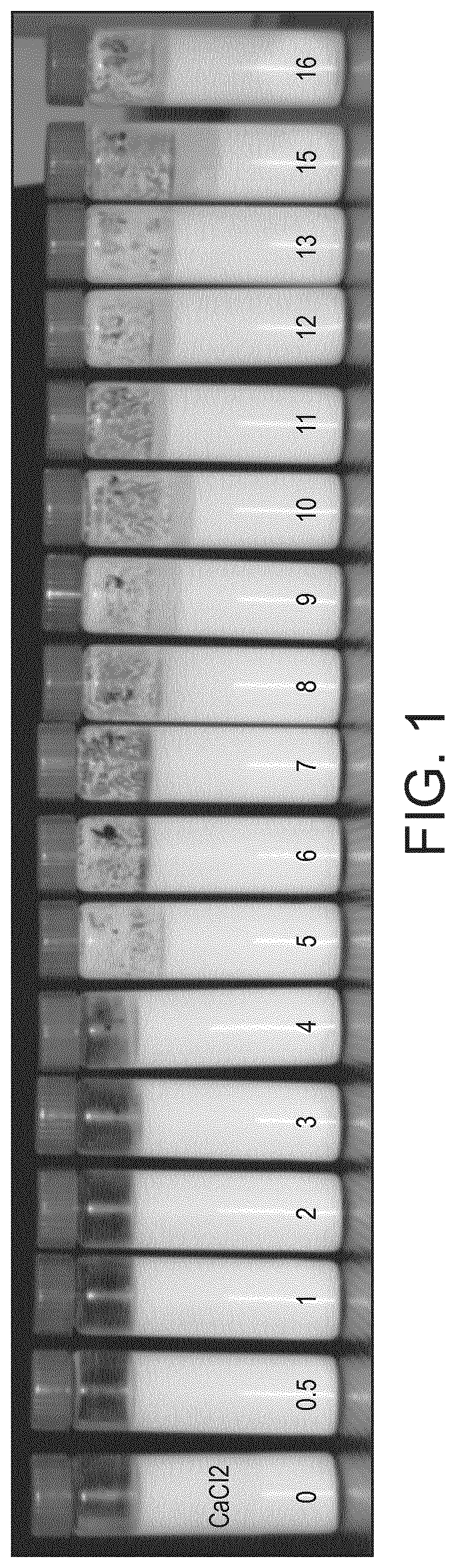

A method of producing a dairy concentrate with free divalent cations protein aggregation

ActiveUS20190373907A1Improve textureImprove mouthfeelMilk preparationConfectioneryMean diameterCell Aggregations

The invention relates to a method of producing a dairy concentrate, comprising the steps of: providing an ingredient composition comprising micellar caseins and whey proteins and having a pH of 6.1-7.1 and a concentration of 3-25 wt. % of proteins, and wherein the ingredient composition has a casein to whey protein ratio of 90 / 10-60 / 40, adding 3-25 mM divalent cations to provide a concentration of 3-8 mM free divalent cations in the ingredient composition, homogenising the ingredient composition; and subsequently pasteurising and stirring the ingredient composition at a temperature of 80°-105° C. for a period of 0.5-3 min to form agglomerated proteins comprising caseins and beta-lactoglobulin from the whey proteins, the agglomerates having a size of 3-50 microns as measured by D(4,3) mean diameter. The invention also relates to a method with an ultra-high temperature treatment of the ingredient mix. Furthermore, the invention relates to a dairy concentrate comprising aggregated proteins comprising micellar casein and whey protein aggregates, wherein the product has a pH of 6.0-7.1, a concentration of 6-55 wt. % milk solids, a casein to whey protein ratio of 90 / 10-60 / 40, and a concentration of 3-8 mM free divalent cations, and wherein the agglomerates having a size of 3-50 microns mean diameter D(4,3) as measured by laser diffraction.

Owner:SOC DES PROD NESTLE SA

Use of a nucleotide for improving the heat stability of an aqueous micellar casein composition

ActiveUS9872888B2Improve thermal stabilityPeptide/protein ingredientsFood ingredient functionsMicellar caseinNucleotide

The invention relates to the use of one or more nucleotides for improving the heat stability of an aqueous micellar casein composition comprising 6 to 20 g per 100 ml of micellar casein, and having a pH of about 6 to 8. The invention also relates to heat-treated liquid nutritional compositions comprising 6 to 20 g, preferably 9-20 g, of protein per 100 ml of the composition and having a pH of about 6 to 8, in which all or a major part of said protein comprises micellar casein, further comprising one or more nucleotides.

Owner:NV NUTRICIA

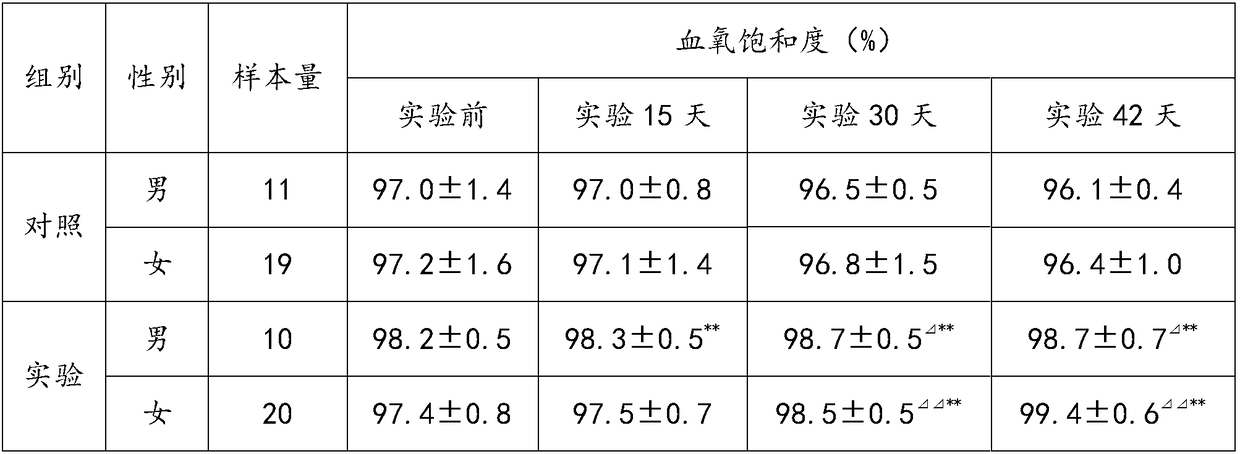

Protein-dense nutritional compositions for use in treating and/or preventing a condition linked to loss of muscle mass and/or strength

PendingUS20200253239A1Fast and high-quality amino acid profilePrevent goodPeptide/protein ingredientsMuscular disorderProtein compositionNutrition

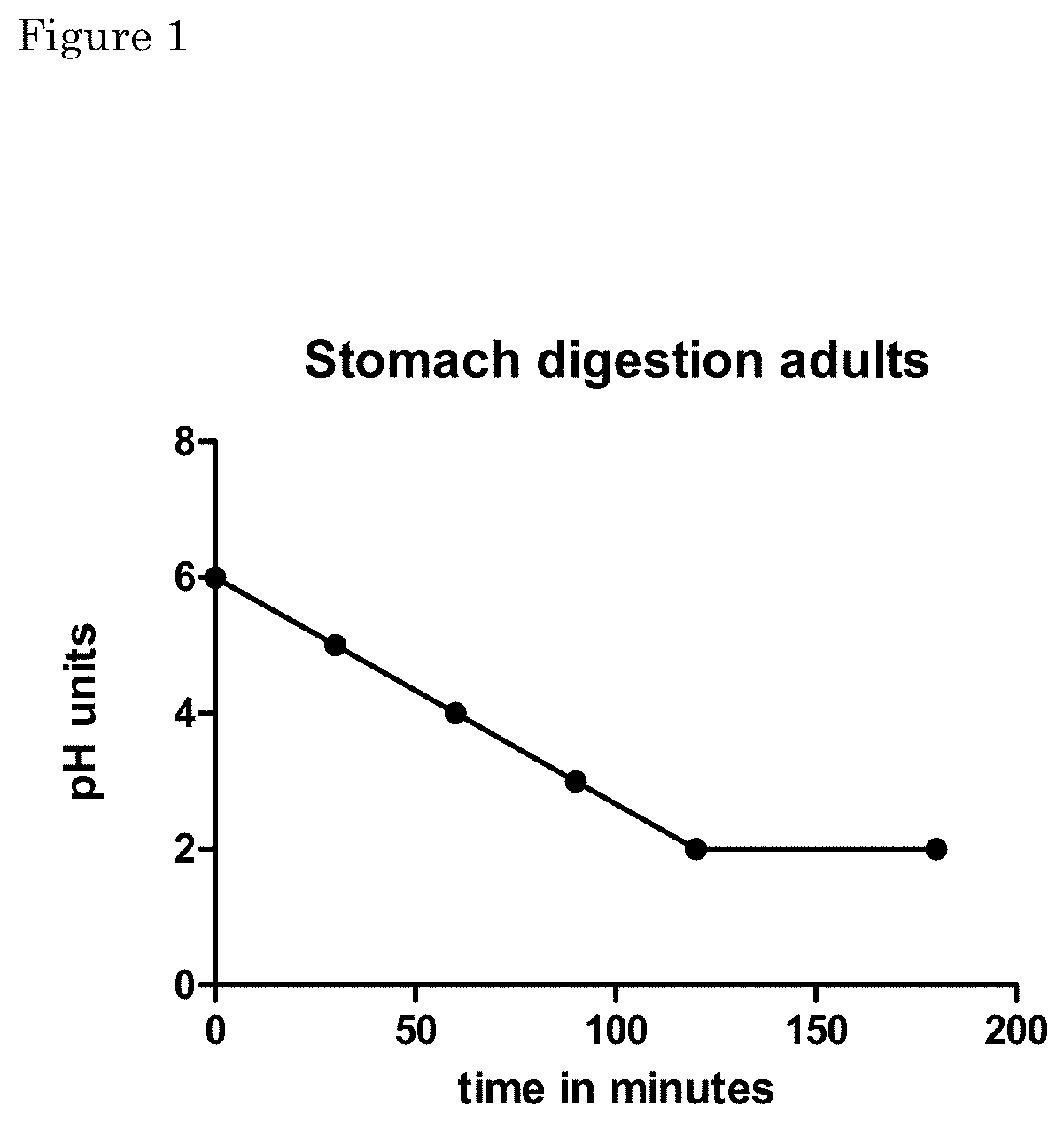

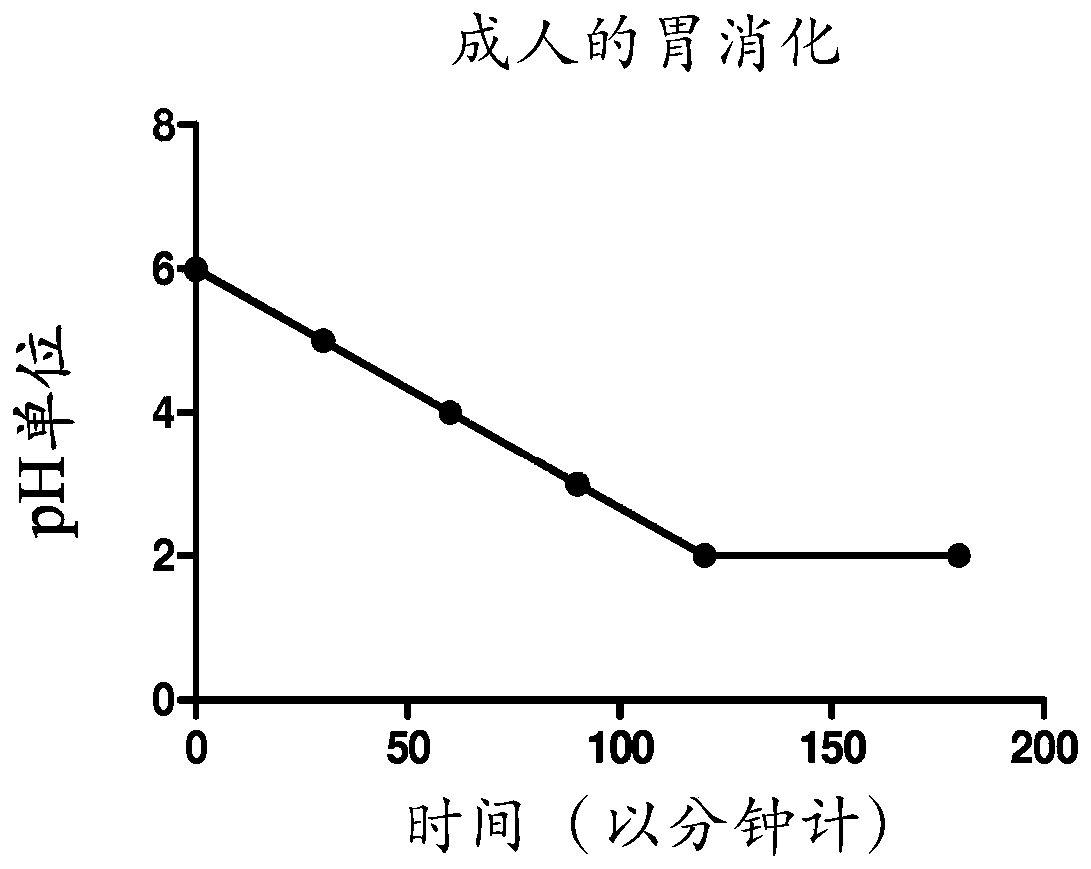

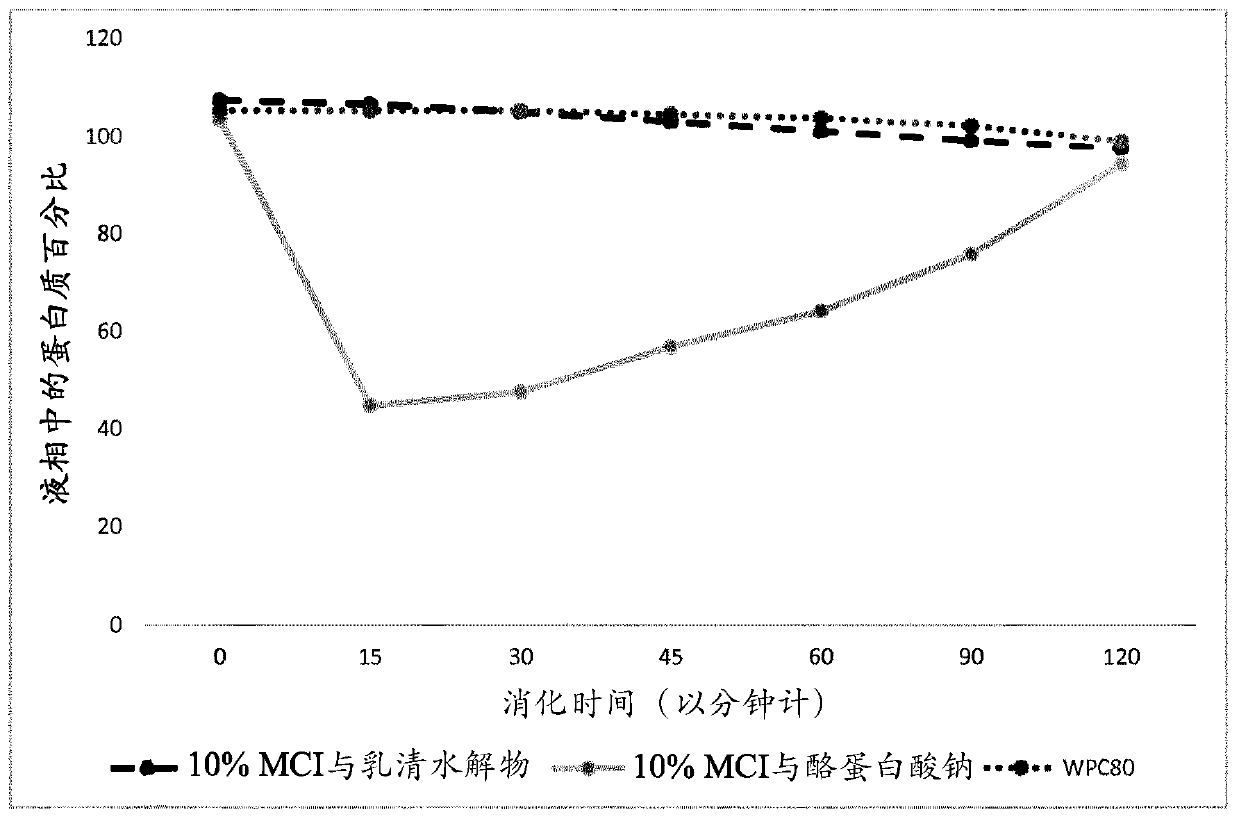

The invention relates to the field of protein-dense liquid nutritional compositions for use in the treatment and / or prevention of a condition linked to loss of muscle mass and / or strength. Provided is a heat-treated liquid high-protein composition comprising at least 10 g of protein per 100 ml of the composition, wherein at least 40 wt. % of the protein is micellar casein and at least 10 wt. % of the protein is hydrolysed whey protein having a degree of hydrolysation of at least 5%, and wherein the weight ratio of micellar casein to hydrolysed whey protein is in the range of 40:60 to 90:10, for use in any one or more of the following:a) preventing or reducing coagulation in the upper gastro-intestinal tract;b) increasing the rate of gastric emptying;c) enhancing protein digestion;d) increasing the blood serum concentration of free essential amino acids, preferably leucine, in a subject.

Owner:FRIESLANDCAMPINA NEDERLAND BV

A method of producing a food or beverage product with free divalent cations protein aggregation

ActiveUS20200037632A1Improve textureImprove mouthfeelMilk preparationFrozen sweetsMilk SerumCell Aggregations

The invention relates to a method of producing a food or beverage product, comprising the steps of: providing an ingredient composition comprising, micellar caseins and whey proteins and having a pH of 6.1-7.1 and a concentration of 1-15 wt. % of proteins, and wherein the ingredient composition has a casein to whey protein ratio of 90 / 10-60 / 40, adding 3-25 mM divalent cations to provide a concentration of 3-8 mM free divalent cations in the ingredient composition, homogenising the ingredient composition; and subsequently pasteurising and stirring the ingredient composition at a temperature of 80°-100° C. for a period of 0.5-3 min to form agglomerated proteins comprising caseins and beta-lactoglobulin from the whey proteins, the agglomerates having a size of 5-50 microns as measured by D(4, 3) mean diameter. The invention relates also to a food or beverage product comprising aggregated proteins comprising micellar casein and whey protein aggregates, wherein the product has a pH of 6.1-7.1, a concentration of 6-40 wt. % milk solids, a casein to whey protein ratio of 90 / 10-60 / 40, and a concentration of 3-8 mM free divalent cations, and wherein the agglomerates having a size of 5-50 microns mean diameter D(4, 3) as measured by laser diffraction.

Owner:SOC DES PROD NESTLE SA

Protein-dense nutritional compositions for use in treating and/or preventing condition linked to loss of muscle mass and/or strength

The invention relates to the field of protein-dense liquid nutritional compositions for use in the treatment and / or prevention of a condition linked to loss of muscle mass and / or strength. Provided isa heat-treated liquid high-protein composition comprising at least 10 g of protein per 100 ml of the composition, wherein at least 40 wt.% of the protein is micellar casein and at least 10 wt.% of the protein is hydrolysed whey protein having a degree of hydrolysation of at least 5%, and the weight ratio of micellar casein to hydrolysed whey protein is in the range of 40:60 to 90:10, for use in any one or more of the following of a) preventing or reducing coagulation in the upper gastro-intestinal tract; b) increasing the rate of gastric emptying; c) enhancing protein digestion; d) increasingthe blood serum concentration of free essential amino acids, preferably leucine, in the subject.

Owner:FRIESLANDCAMPINA NEDERLAND BV

A method of producing a food or beverage product with free divalent cations dairy and plant protein aggregation

ActiveUS20200178563A1Improve textureImprove mouthfeelMilk preparationProtein composition from milkBiotechnologyMilk Serum

The invention relates to a method of producing a food or beverage product, comprising the steps of: providing an ingredient composition comprising micellar caseins, whey protein and plant protein having a pH of 5.9-7.1, preferably 6.2-6.8, and having a concentration of 1 to 15 wt. % of total proteins, and wherein the composition has a micellar casein to whey protein ratio of, 90 / 10 to 60 / 40 and a micellar caseins and whey protein to plant protein ratio of 80 / 20 to 20 / 80, adding divalent cations to provide a concentration of 2.0-10 mM free divalent cations in the ingredient composition and subsequently heat treating the ingredient composition to form agglomerated proteins comprising micellar casein, whey protein and plant proteins, the agglomerates having a size of 5 to 50 microns as measured by D(4,3) mean diameter as measured by laser diffraction. The invention also relates to a product obtained by this method.

Owner:SOC DES PROD NESTLE SA

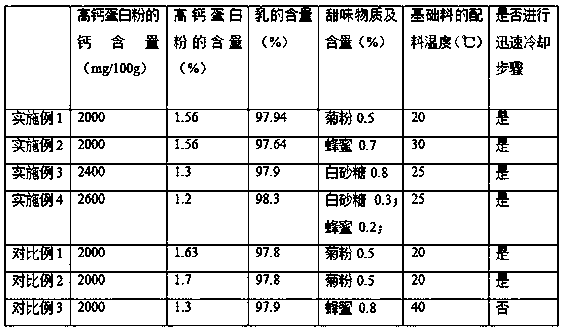

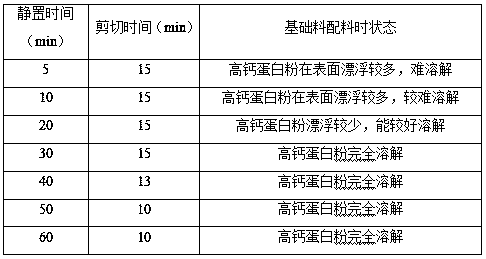

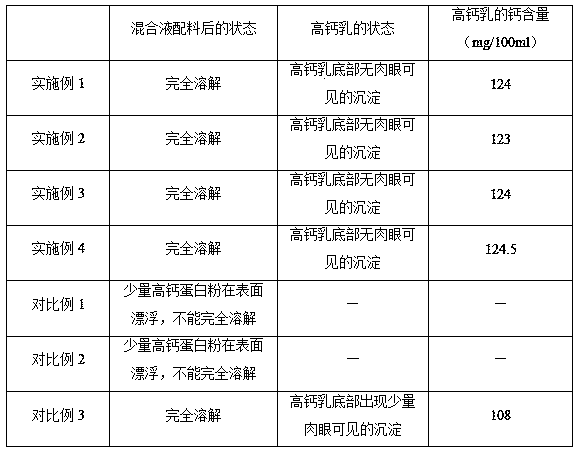

Preparation method of high-calcium milk, preparation method of high-calcium low-fat milk, high-calcium milk product and high-calcium low-fat milk product

ActiveCN110495497AMeet health needsIncreased proportion of hydrophilic groupsMilk preparationMilk preservationBiotechnologyCalcium protein

The invention provides a preparation method of high-calcium milk, a preparation method of high-calcium low-fat milk, a high-calcium milk product and a high-calcium low-fat milk product. The preparation method of the high-calcium milk and the preparation method of the high-calcium low-fat milk comprise the following steps of firstly preparing high-calcium protein powder, sweetening substances and milk, wherein high-calcium protein powder which is obtained by separating and concentrating micellar casein, and of which the calcium content is greater than or equal to 2000mg / 100g is used as the high-calcium protein powder, based on the total amount of the high-calcium milk being 100%, the percentage by weight of the sweetening substances is 0.5-0.8%, the total content of the high-calcium proteinpowder and the milk is within the limit that the content of calcium in the high-calcium protein powder and the milk in finished products of the high-calcium milk is greater than or equal to 120mg / 100ml, and full fat raw milk of which the calcium content is 95-115mg / 100g is used as the milk; during preparation, firstly, uniformly mixing the high-calcium protein powder with the sweetening substances to obtain a mixture, then pouring the mixture into milk which is preheated to 20-30 DEG C in advance, and performing uniform mixing; then performing rapid cooling to 4-10 DEG C; and finally, performing preheating to 65-70 DEG C, performing homogenizing, performing sterilizing, performing cooling and performing filling to obtain finished products. The high-calcium milk product can meet health requirements of consumers for pure milk products free from food additives.

Owner:FUJIAN CHANGFU DAIRY

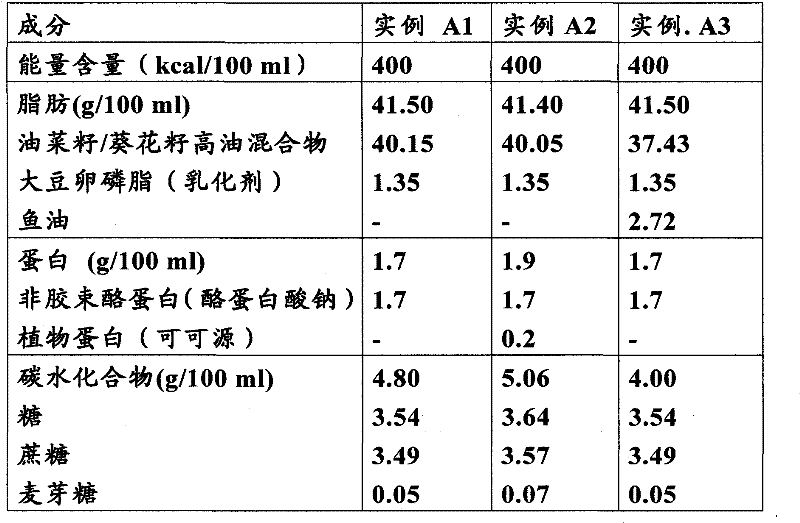

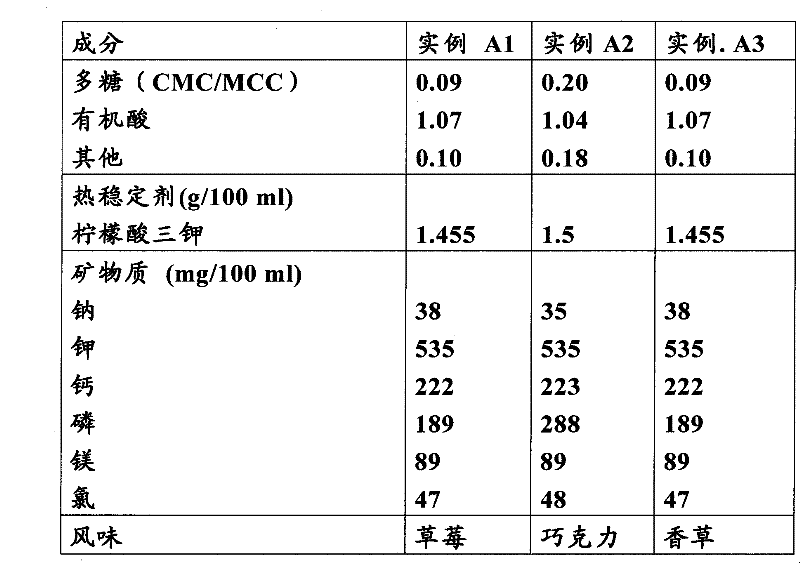

Energy-rich liquid nutritional composition having improved organoleptic properties

The object of the present invention is to provide a liquid enteral composition for providing nutrition, either as a supplement, or as a complete nutrition, comprising a high protein content, in particular micellar casein as major protein source,in a small volume of liquid, in particular 6 to 20 g protein per 100 ml of the liquid composition, the composition further comprising lactic acid andhaving a pH in the range of 6 to 8. It is also an object of the invention to provide an improved manufacturing process for such liquid enteral compositions.

Owner:NV NUTRICIA

Method of producing a dairy concentrate with free divalent cations protein aggregation

ActiveUS11089791B2Low in fatMaintain good propertiesMilk preparationConfectioneryBiotechnologyMilk Serum

The invention relates to a method of producing a dairy concentrate, comprising the steps of: providing an ingredient composition comprising micellar caseins and whey proteins and having a pH of 6.1-7.1 and a concentration of 3-25 wt. % of proteins, and wherein the ingredient composition has a casein to whey protein ratio of 90 / 10-60 / 40, adding 3-25 mM divalent cations to provide a concentration of 3-8 mM free divalent cations in the ingredient composition, homogenising the ingredient composition; and subsequently pasteurising and stirring the ingredient composition at a temperature of 80°-105° C. for a period of 0.5-3 min to form agglomerated proteins comprising caseins and beta-lactoglobulin from the whey proteins, the agglomerates having a size of 3-50 microns as measured by D(4,3) mean diameter. The invention also relates to a method with an ultra-high temperature treatment of the ingredient mix. Furthermore, the invention relates to a dairy concentrate comprising aggregated proteins comprising micellar casein and whey protein aggregates, wherein the product has a pH of 6.0-7.1, a concentration of 6-55 wt. % milk solids, a casein to whey protein ratio of 90 / 10-60 / 40, and a concentration of 3-8 mM free divalent cations, and wherein the agglomerates having a size of 3-50 microns mean diameter D(4,3) as measured by laser diffraction.

Owner:SOC DES PROD NESTLE SA

Liquid enteral nutritional composition with a low monovalent metal ion content

ActiveUS10092625B2High in proteinLow viscosityPeptide/protein ingredientsMetabolism disorderIon contentProtein solution

Heat-treated liquid enteral nutritional composition with a low monovalent metal ion content are provided that contain micellar casein and optionally caseinate, and in which the total amount of monovalent metal ions is less than 25 mg / g of protein. Also, heat-treated liquid enteral nutritional compositions are disclosed comprising 10 to 20 g of protein per 100 ml of the composition, in which all or a major part of said protein comprises micellar casein. Also, a method is disclosed for producing the composition according to the invention, comprising a step wherein an aqueous protein solution in which all or a major part of said protein comprises micellar casein, is subjected to an evaporation step.

Owner:NV NUTRICIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com