Functional digestible micelle-state casein powder and preparation method thereof

An easy-to-digest, functional technology, applied in animal protein processing, food ingredient functions, protein food ingredients, etc., can solve the problems of low binding rate of active small molecules, complicated preparation process, poor digestibility, etc., and achieve high efficiency, high purity and rich Accumulates, promotes well-bound, easily digestible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

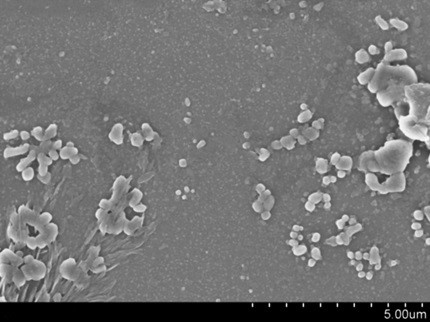

[0032] Example 1, functional digestible micellar casein powder loaded with phenethyl caffeate and its preparation method, the specific steps are as follows:

[0033] (1) Raw material pretreatment: Centrifuge UHT sterilized milk at 6000g for 20 minutes, discard the upper layer of fat, and collect the lower layer of skim milk;

[0034] (2) Alkalinization treatment: use 0.5mol / L sodium hydroxide to adjust the pH of skim milk to 8.0;

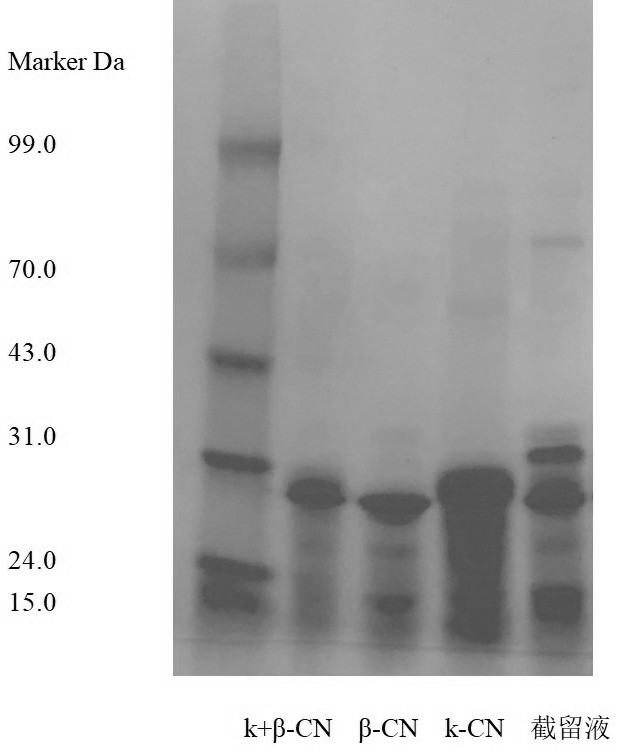

[0035] (3) Ultrafiltration: Concentrate skim milk with a 100kDa ultrafiltration membrane. The inlet pressure of the filter membrane is 1.0 MPa, and the concentration factor is 5. Add 6 times the volume of the sample to dilute the retentate with deionized water. Filtrate and concentrate 5 times to obtain the micellar casein retentate;

[0036] (4) Acidification and ultrasonic treatment: Divide the retentate into 100mL portions, use 0.5mol / L hydrochloric acid to adjust the pH to 6.2, place it in a jacketed reactor with a 25°C circulating water bath, ...

Embodiment 2

[0044] Example 2, functional digestible micellar casein powder loaded with puerarin and its preparation method, the specific steps are as follows:

[0045] (1) Raw material pretreatment: Centrifuge the pasteurized milk at 4000g for 30 minutes, discard the upper layer of fat, and collect the lower layer of skim milk;

[0046] (2) Alkalinization treatment: use 1mol / L sodium hydroxide to adjust the pH of skim milk to 7.2;

[0047] (3) Ultrafiltration: Concentrate skim milk with a 100kDa ultrafiltration membrane. The inlet pressure of the filter membrane is 0.5MPa, and the concentration factor is 3. Add deionized water 3 times the volume of the sample to dilute the retentate. Filtrate and concentrate 3 times to obtain the micellar casein retentate;

[0048] (4) Acidification and ultrasonic treatment: Divide the retentate into 100mL portions, use 1mol / L hydrochloric acid to adjust the pH to 6.8, place it in a jacketed reactor with a 35°C circulating water bath, and use an ultrason...

Embodiment 3

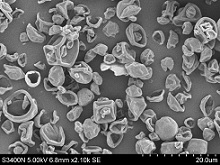

[0056] Embodiment 3, functional digestible micellar casein powder loaded with curcumin and preparation method thereof, the specific steps are as follows:

[0057] (1) Raw material pretreatment: centrifuge pasteurized yak milk at 5000g for 25 minutes, discard the upper layer of fat, and collect the lower layer of skim milk;

[0058] (2) Alkalinization treatment: use 0.8mol / L sodium hydroxide to adjust the pH of skim milk to 7.6;

[0059] (3) Ultrafiltration: Use a 100kDa ultrafiltration membrane to concentrate skim milk. The inlet pressure of the filter membrane is 0.7MPa, and the concentration factor is 4. Add 4.5 times the volume of the sample to dilute the retentate with deionized water. Filter and concentrate 4 times to obtain the micellar casein retentate;

[0060] (4) Acidification and ultrasonic treatment: Divide the retentate into 100mL portions, use 0.8mol / L hydrochloric acid to adjust the pH to 6.5, place it in a jacketed reactor with a 30°C circulating water bath, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com