Multifunctional coating applicable to urinary medical apparatus and preparation method and application thereof

A multifunctional, medical device technology, applied in coatings, medical science, catheters, etc., can solve the problems of complex construction methods, serious threats to patients' lives, poor applicability, etc., to improve the effect of long-term sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The application also provides a preparation method for a multifunctional coating, comprising the following steps:

[0034] Mix the bio-based anionic polymer and the organic silicon quaternary ammonium salt solution, and the obtained precipitate is centrifugally cleaned, dried and dissolved in an organic reagent to obtain a polyelectrolyte complex organic solution;

[0035] The polyelectrolyte composite organic solution is dip-coated on the surface of the hydroxylated matrix, and thermally cured to obtain a multifunctional coating.

[0036] In the above preparation process, the concentration of the organic silicon quaternary ammonium salt solution is 0.001-5 g / mL, and the concentration of the polyelectrolyte complex organic solution is 0.001-10 g / mL. The bio-based anionic polymer and the organosilicon quaternary ammonium salt solution are mixed in an organic solvent, wherein the organic solvent is selected from one or more of methanol, ethanol, methylene chloride, aceton...

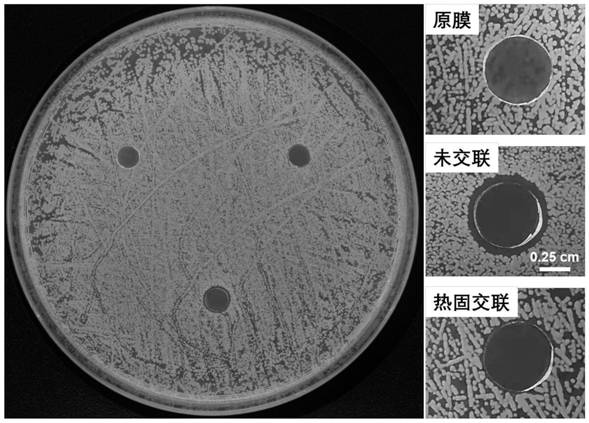

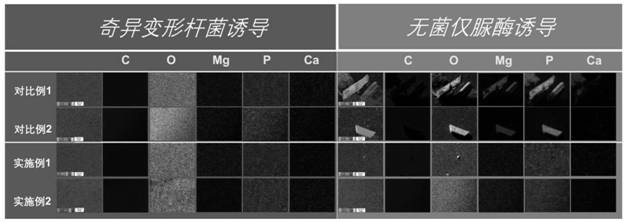

Embodiment 1

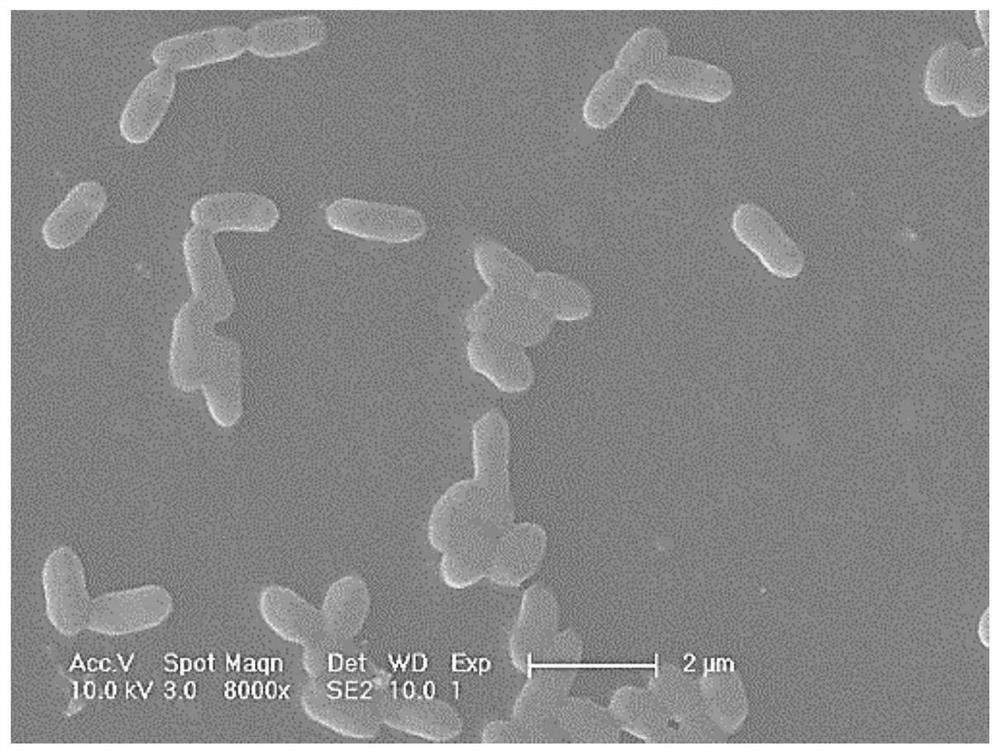

[0048] A) Using commercially available sodium hyaluronic acid (HA) as a bio-based anionic polymer, 2 wt % of dimethyltetradecyl [3-(trimethoxysilyl) propyl] ammonium chloride ( Si-N 14 + ) aqueous solution was added to 2wt% HA aqueous solution, fully stirred for 5 minutes, and the time for dropping was 15 minutes; after that, the white precipitate at the bottom was collected, washed 6 times with deionized water, and HA / Si-N was obtained after freeze-drying 14 + Medical composite coating agent;

[0049] B) Put the medical polyurethane ureteral stent into the plasma reaction chamber, and treat the sample with plasma for 15 minutes to obtain the surface hydroxylated polyurethane stent;

[0050] C) Soak the hydroxylated polyurethane material obtained in step B) in the compound ethanol solution obtained in step A) for 3 minutes, and dry to obtain a physically functioning composite intermediate coated polyurethane material.

[0051] D) Put the polyurethane material coated with t...

Embodiment 2

[0053] A) Using commercially available chondroitin sulfate sodium salt (CS) as a bio-based anionic polymer, 2 wt% of dimethyloctadecyl[3-(trimethoxysilyl)propyl]ammonium chloride ( Si-N 18 + ) aqueous solution was added to 1wt% CS aqueous solution, fully stirred for 5 minutes, and the time for dropping was 15 minutes; after that, the white precipitate at the bottom was collected, washed 6 times with deionized water, and HA / Si-N was obtained after freeze-drying 18 + Medical composite coating agent;

[0054] B) Put the medical silicone rubber urinary catheter into the plasma reaction chamber, and treat the sample with plasma for 10 minutes to obtain surface hydroxylated silicone rubber;

[0055] C) Soak the hydroxylated silicone rubber material obtained in the step B) in the composite methanol solution obtained in the step A) for 1 min, and dry to obtain a physically active composite intermediate coating silicone rubber material;

[0056] D) Put the silicone rubber material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com