Method for inducing and synthesizing TiO2-ZnO by adsorbing enzyme on functionalized graphene oxide

A graphene oxide, oxide technology, applied in the field of nanomaterials, biomimetic mineralization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

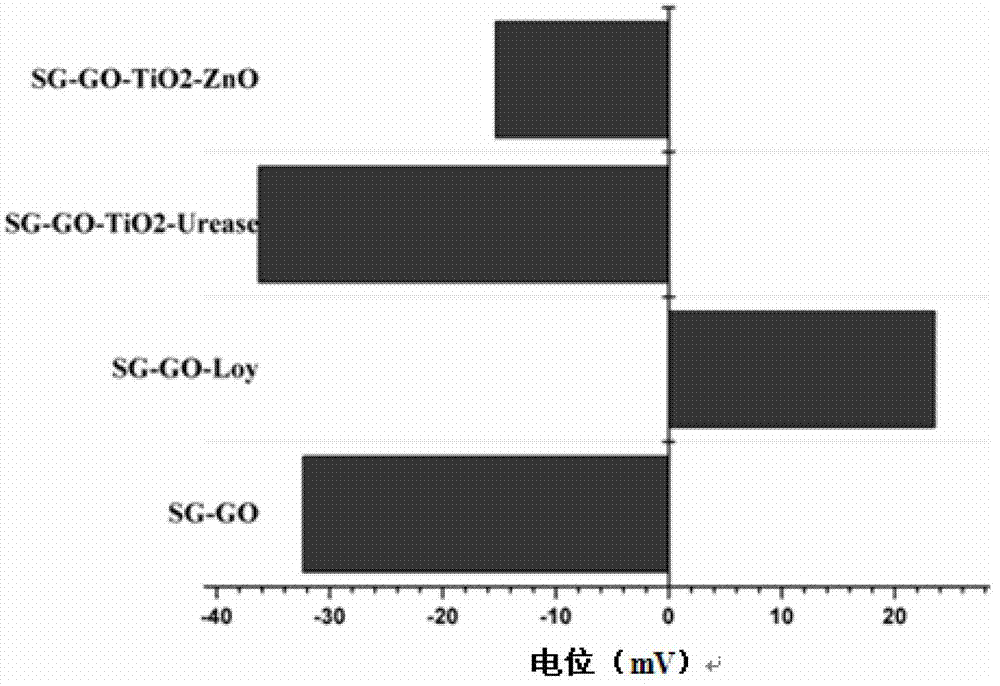

[0018] 1. Adsorb 5mL solvent green (8-hydroxy-1,3,6-pyrenetrisulfonic acid trisodium salt, SG, 0.5g / L) on 20mL graphene oxide ( GO, 0.5g / L), after magnetic stirring for 12h, the residual solvent green in the solution was washed by centrifugation with deionized water, and this was repeated three times to obtain functionalized graphene oxide.

[0019] 2. Adsorb 20mL lysozyme (Loy, 1g / L) on the 20mL functionalized graphene oxide (SG‐GO, 0.5g / L) in step 1. under the above mild environment by electrostatic attraction, and stir magnetically After 0.5 h, the remaining Loy in the solution was washed by centrifugation with deionized water, and the process was repeated three times to obtain a composite soft template of functionalized graphene oxide and lysozyme.

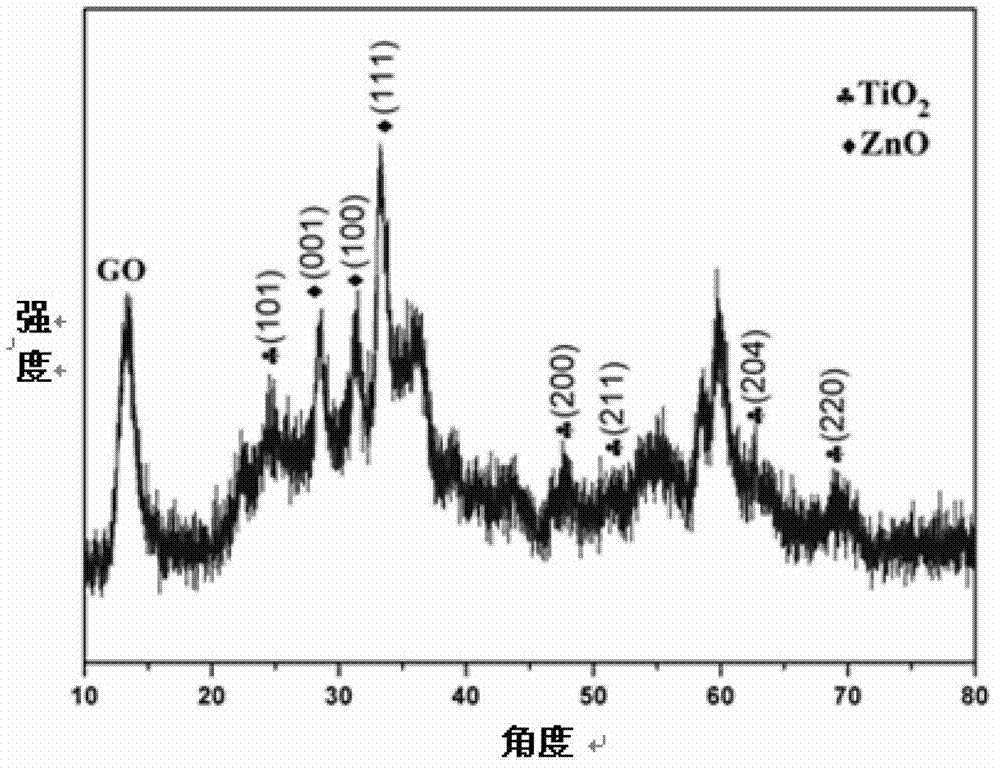

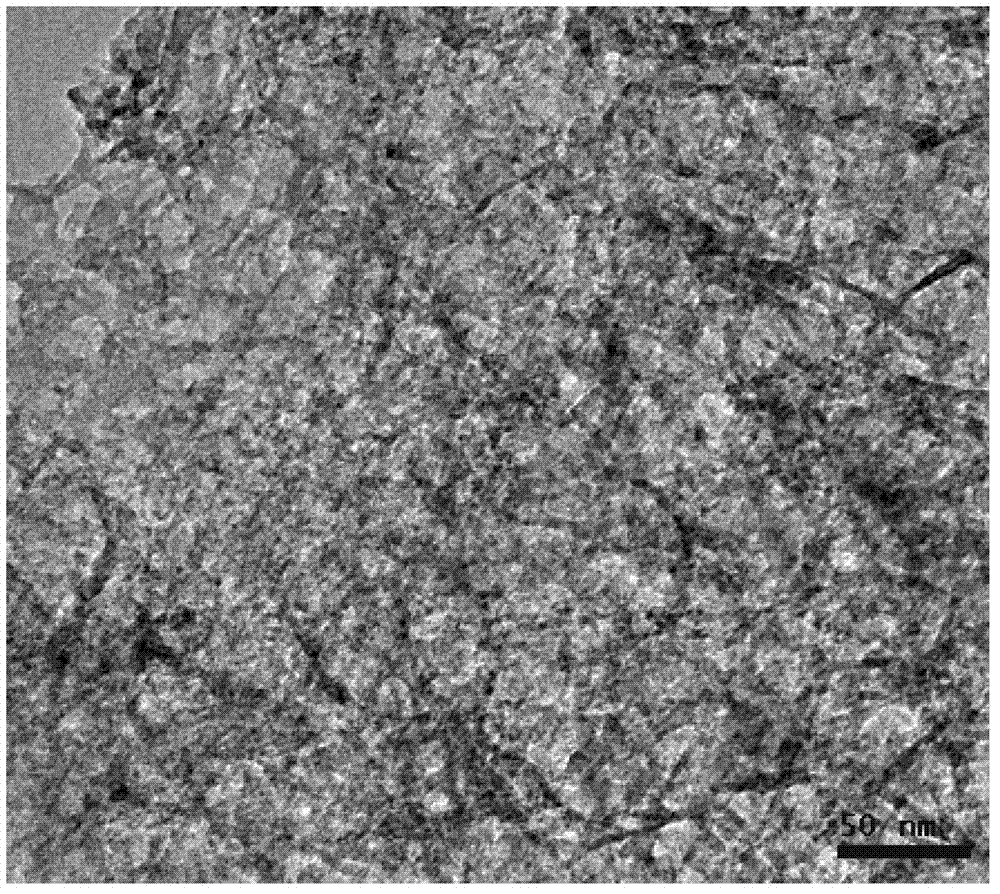

[0020] 3. Disperse the composite template of functionalized graphene oxide and lysozyme in step 2. in a certain amount of deionized water under the above-mentioned mild environmental conditions. After the ultrasonic wave is un...

Embodiment 2

[0023] 1. Adsorb 10mL solvent green (8-hydroxy-1,3,6-pyrene trisulfonic acid trisodium salt, SG, 0.5g / L) on 20mL graphene oxide ( GO, 0.5g / L), after magnetic stirring for 12h, the residual solvent green in the solution was washed by centrifugation with deionized water, and this was repeated three times to obtain functionalized graphene oxide.

[0024] 2. Adsorb 20mL lysozyme (Loy, 1g / L) on the 20mL functionalized graphene oxide (SG‐GO, 0.5g / L) in step 1. under the above mild environment by electrostatic attraction, and stir magnetically After 0.5 h, the remaining Loy in the solution was washed by centrifugation with deionized water, and this was repeated three times to obtain a composite soft template (GO-SG-Loy) of functionalized graphene oxide and lysozyme.

[0025] 3. Disperse the composite template of functionalized graphene oxide and lysozyme in step 2. in a certain amount of deionized water under the above-mentioned mild environmental conditions. After the ultrasonic wav...

Embodiment 3

[0028]1. Adsorb 20mL solvent green (8-hydroxy-1,3,6-pyrenetrisulfonic acid trisodium salt, SG, 0.5g / L) on 20mL graphene oxide ( GO, 0.5g / L), after magnetic stirring for 12h, the residual solvent green in the solution was washed by centrifugation with deionized water, and this was repeated three times to obtain functionalized graphene oxide.

[0029] 2. Adsorb 20mL lysozyme (Loy, 1g / L) on the 20mL functionalized graphene oxide (SG‐GO, 0.5g / L) in step 1. under the above mild environment by electrostatic attraction, and stir magnetically After 0.5 h, the remaining Loy in the solution was washed by centrifugation with deionized water, and this was repeated three times to obtain a composite soft template (GO-SG-Loy) of functionalized graphene oxide and lysozyme.

[0030] 3. Disperse the composite template of functionalized graphene oxide and lysozyme in step 2. in a certain amount of deionized water under the above-mentioned mild environmental conditions. After the ultrasonic wave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com