Blade equipped with a cooling system, associated guide vanes assembly and associated turbomachine

A cooling system, turbine technology, applied in the direction of supporting elements of blades, engine cooling, turbine/propulsion cooling, etc., can solve the problems of air loss, inability to use cooling blades or turbines, cold air leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following embodiments are examples. Although the description refers to one or more embodiments, this does not necessarily mean that each reference refers to the same embodiment, or that the features are only applicable to a single embodiment. Individual features of different embodiments can also be combined to provide other embodiments. In the drawings, scales and proportions are not strictly observed, which is for the purpose of illustration and clarity.

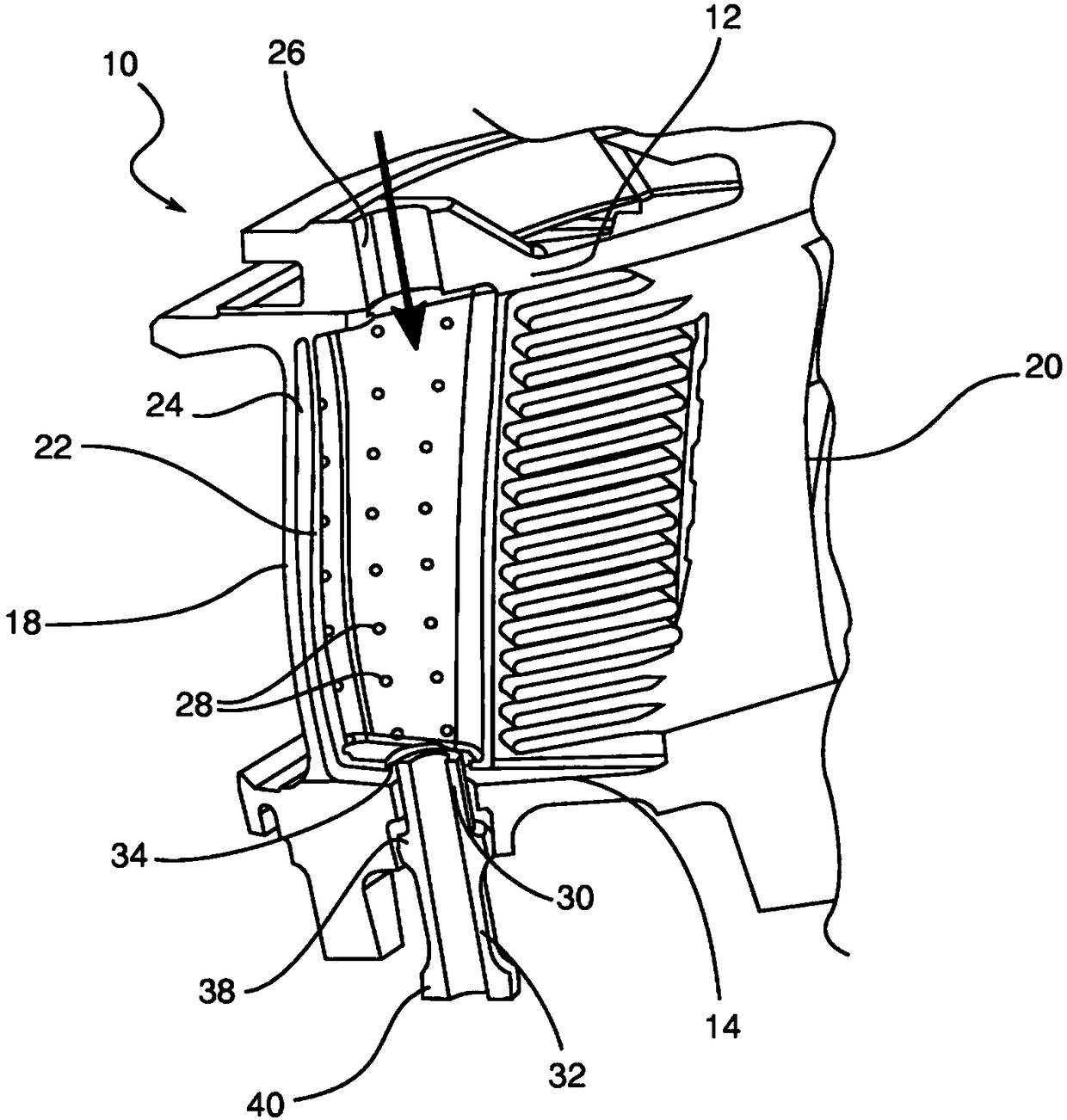

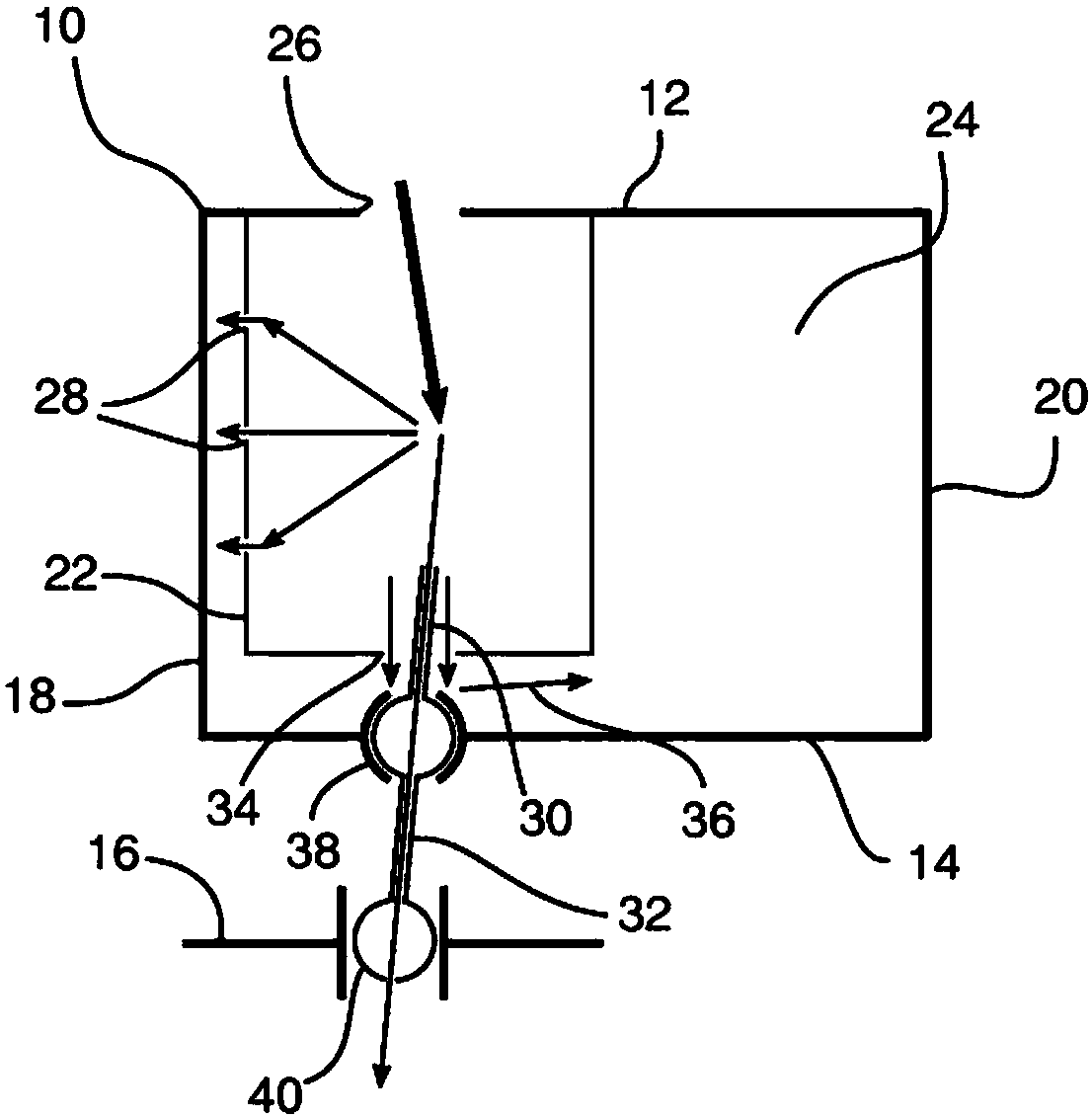

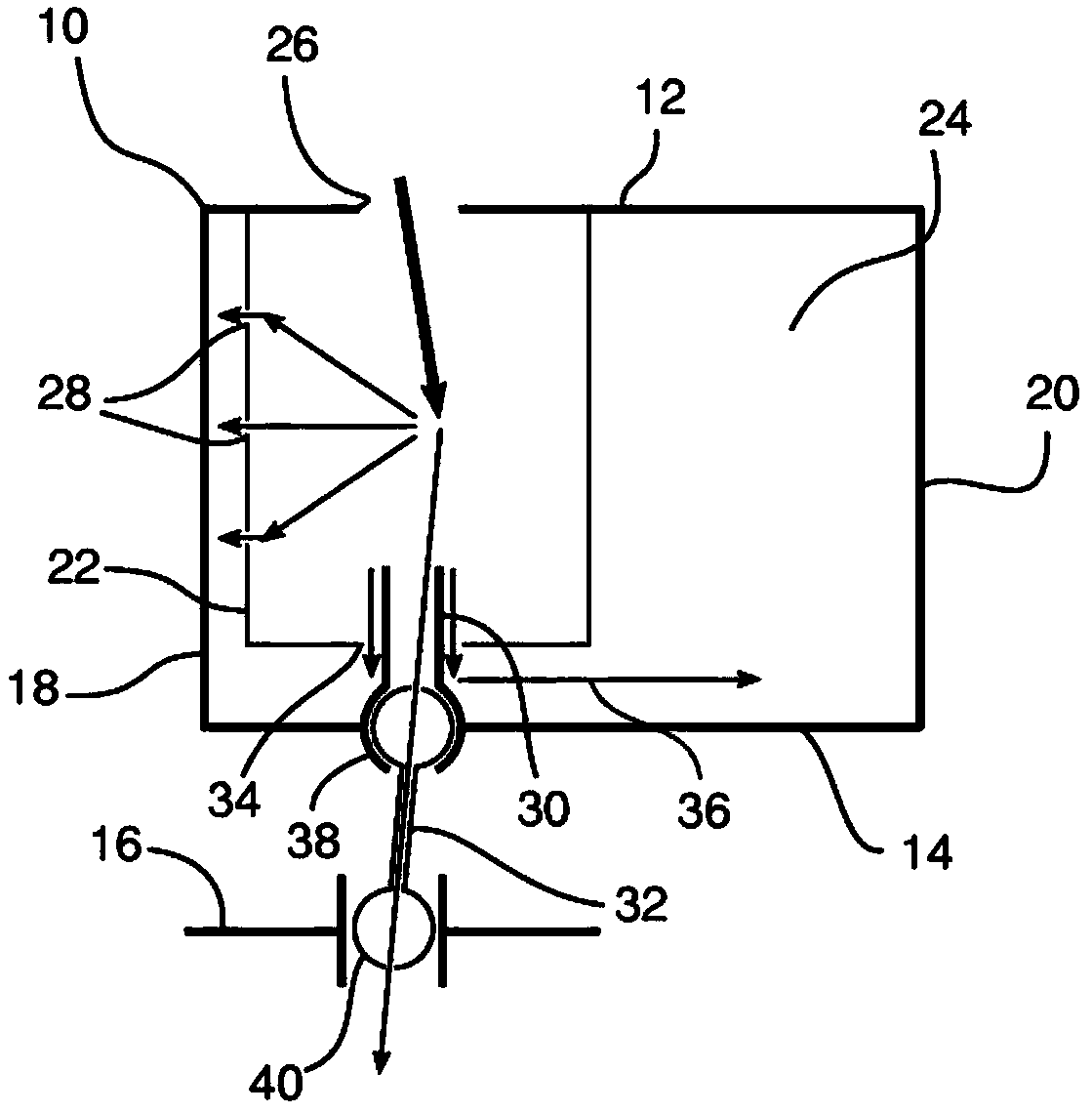

[0037] Figure 1 to Figure 3 ( figure 1 As a perspective view and figure 2 with image 3 As a cross-sectional view), the blade 10 of the guide vane assembly of the turbine is schematically shown. For example, the blade 10 arranged in a turbine includes a portion called the outer meridian 12 on the side of the combustion chamber (not shown) of the turbine, and a portion called the inner meridian 14 on the side of the central hub 16 of the turbine. The rotating part of the turbine rotates around the central hub. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com