Excitation system

An excitation system and excitation technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, synchronous motor for single-phase current, etc., can solve the problems of complex installation system, complex production, large rotating mass, etc. , to achieve the effect of reducing complexity, prolonging life and improving material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

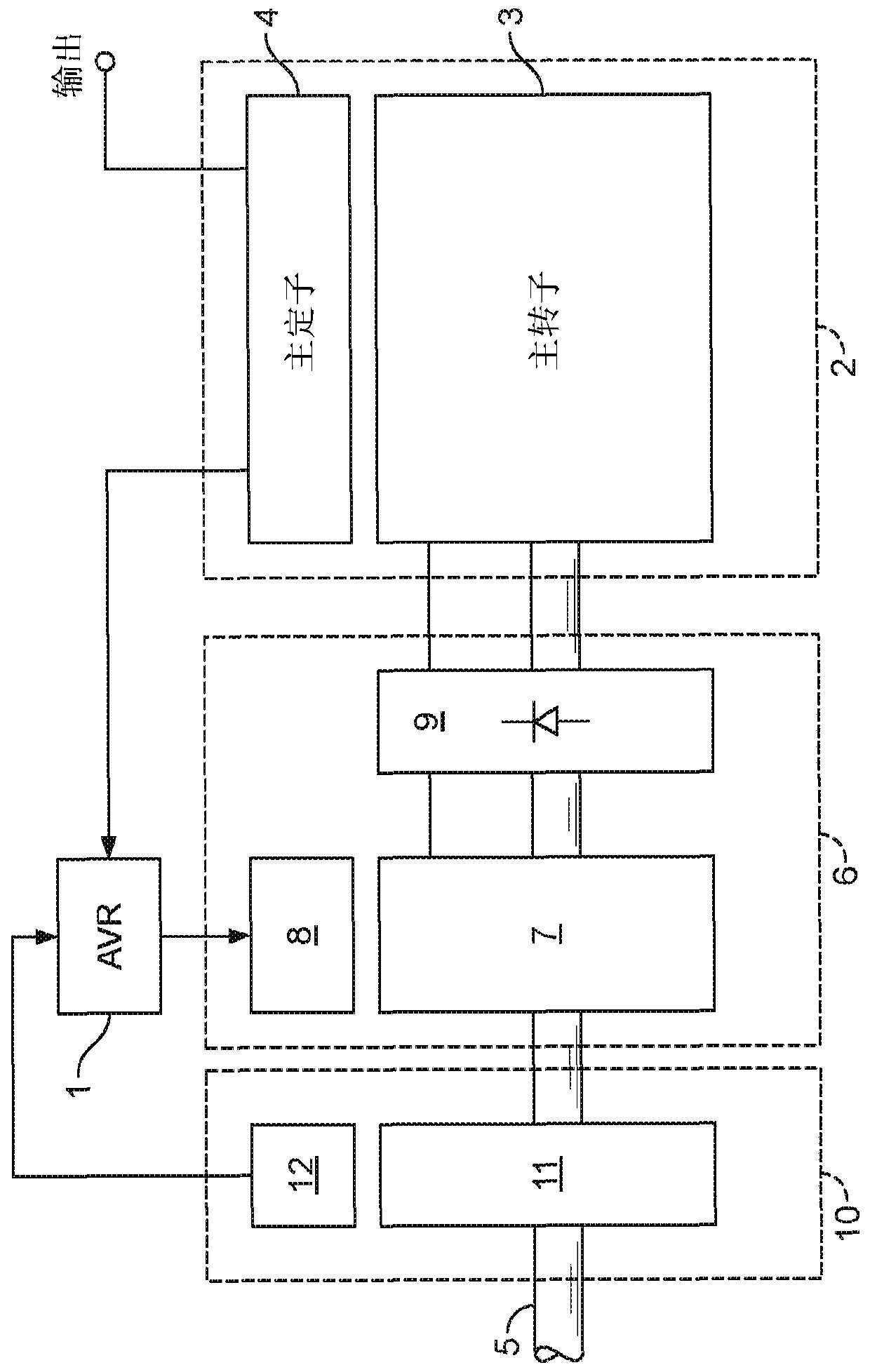

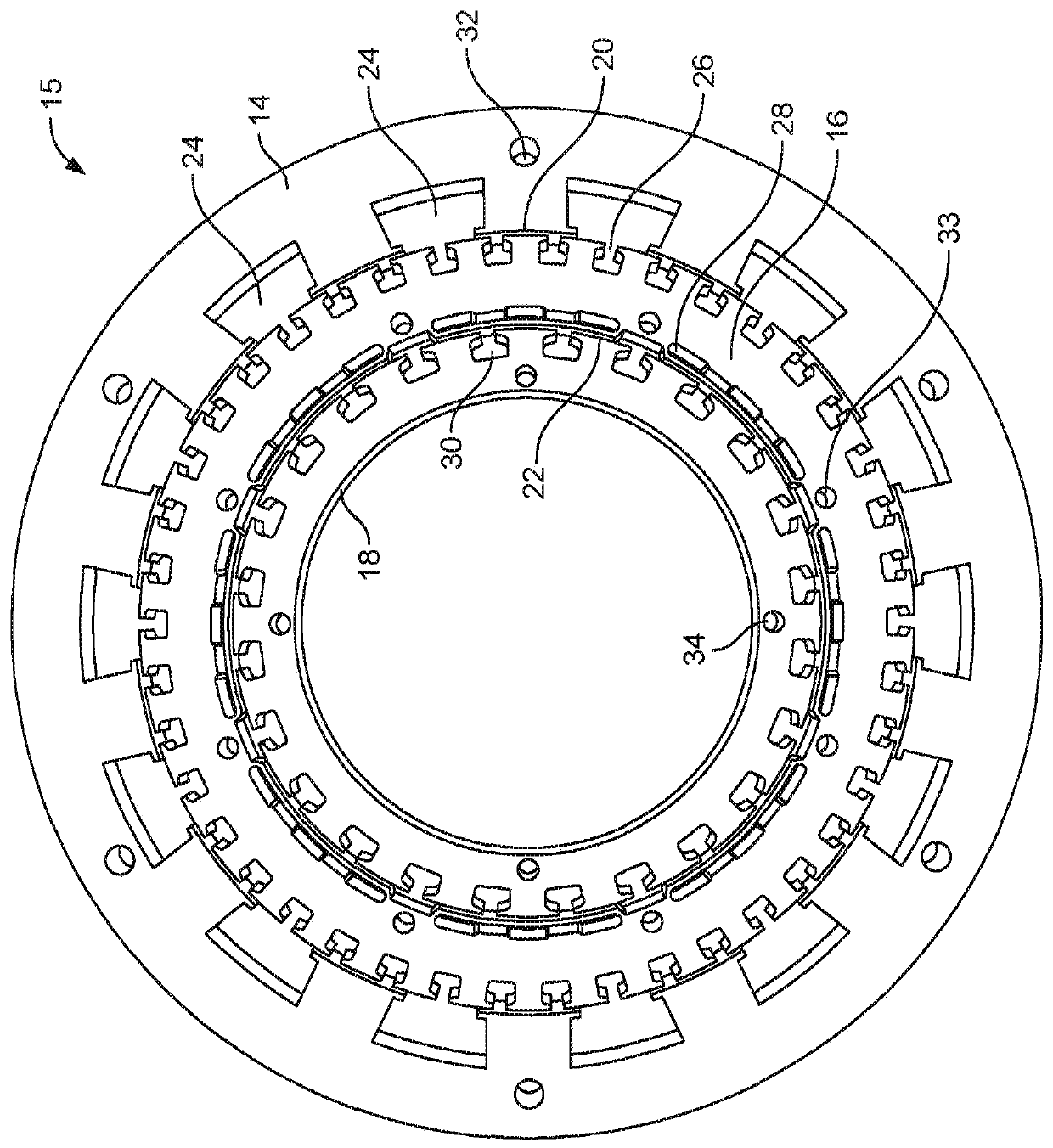

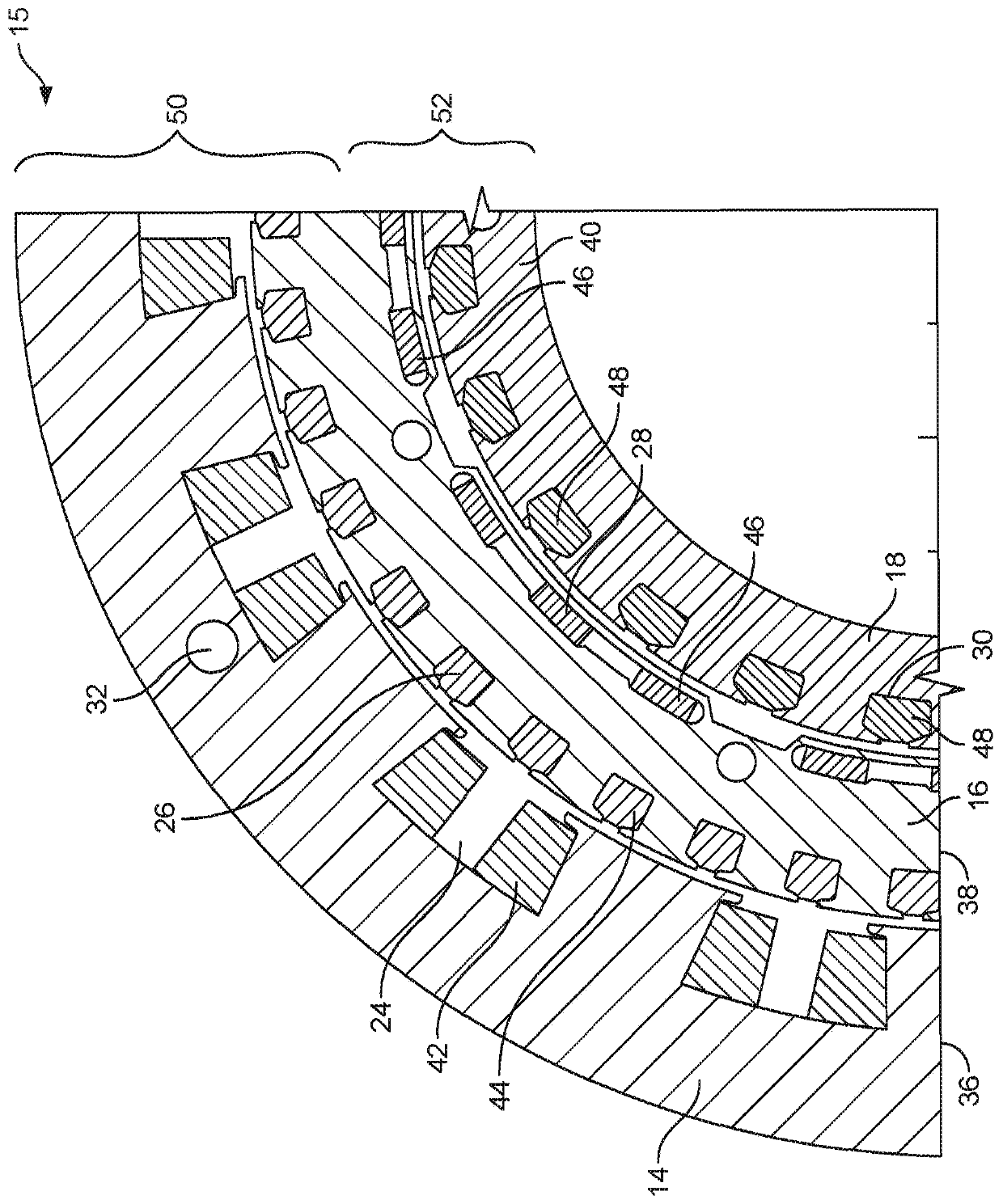

[0145] Figure 19 Portions of an excitation system in another embodiment of the invention are shown. refer to Figure 19 , the excitation system includes the above reference Figure 2 to Figure 17 Combination exciter / PMG 100 of the form described. The combined exciter / PMG 100 includes an exciter stator 102 having stator windings 103 . The exciter stator 102 is mounted on a bracket 104 which may take the form of the bracket 76 described above. PMG stator (in Figure 19 not visible in ) is also mounted on bracket 104 , radially inward of combined exciter / PMG 100 . Figure 19 Also shown in is a rotor support 106 for supporting the combined exciter / PMG rotor core. As in the previous embodiments, a combined exciter / PMG rotor core is located between the exciter stator 102 and the PMG stator.

[0146] In this embodiment, the rotor support 106 takes the form of a rotor hub which is directly attached to the shaft 105 . Vent holes 108 are provided through the rotor hub 106 . Ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com