Shaft workpiece propping and clamping device

A shaft workpiece and top clamping technology, which is applied in the direction of clamping devices, positioning devices, metal processing machinery parts, etc., can solve the problems of reducing processing efficiency, not processing, and cannot process the parts where shaft workpieces are clamped, etc. Achieve the effects of improving processing efficiency and processing accuracy, stable and reliable clamping, and easy clamping and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

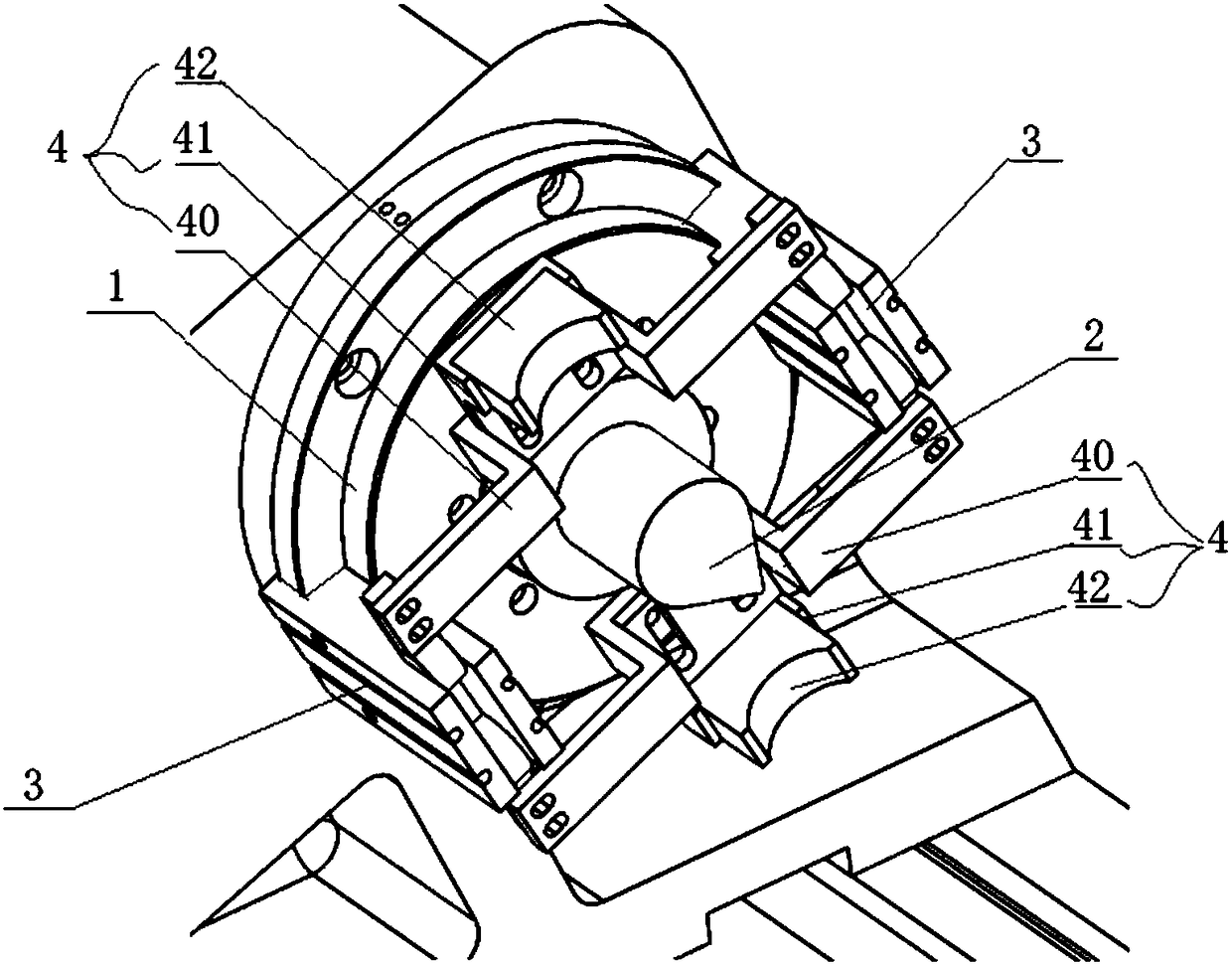

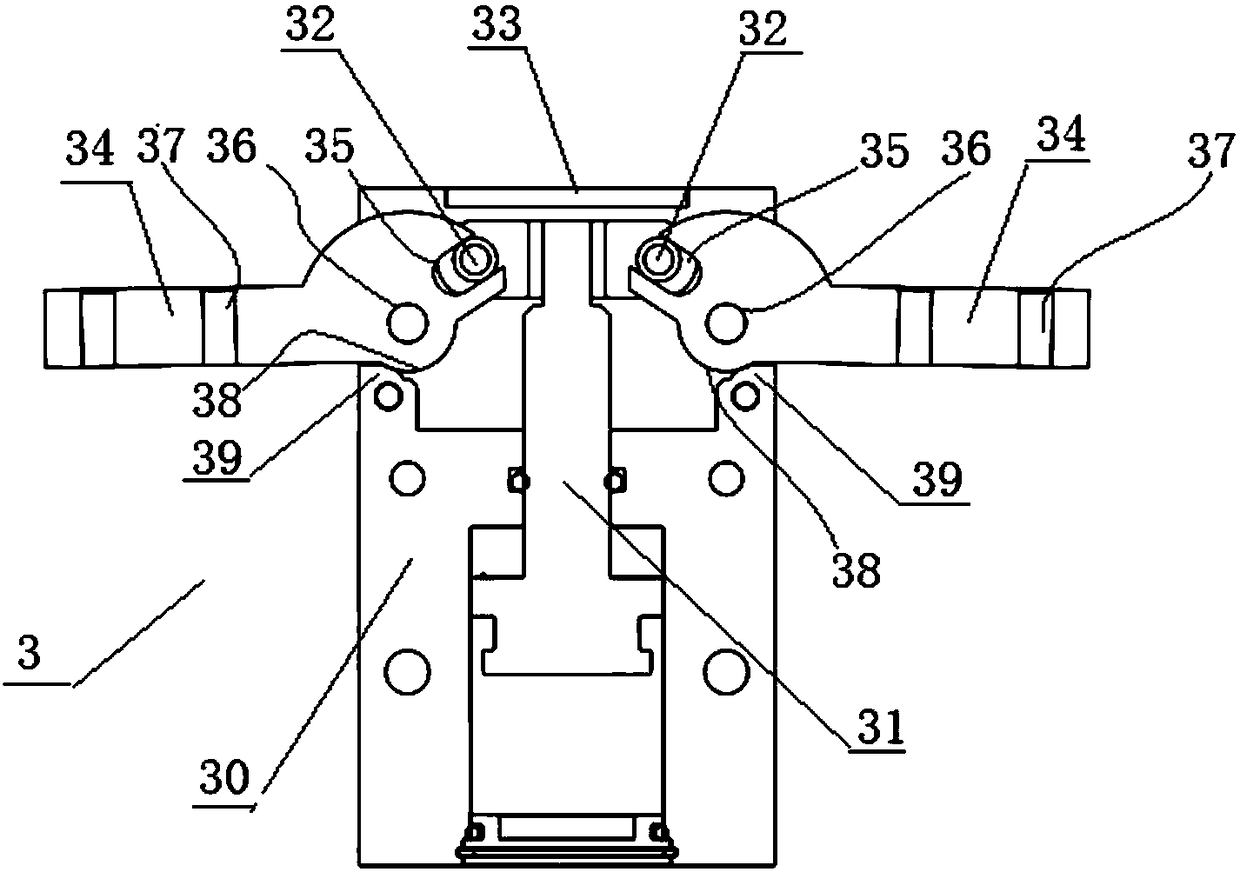

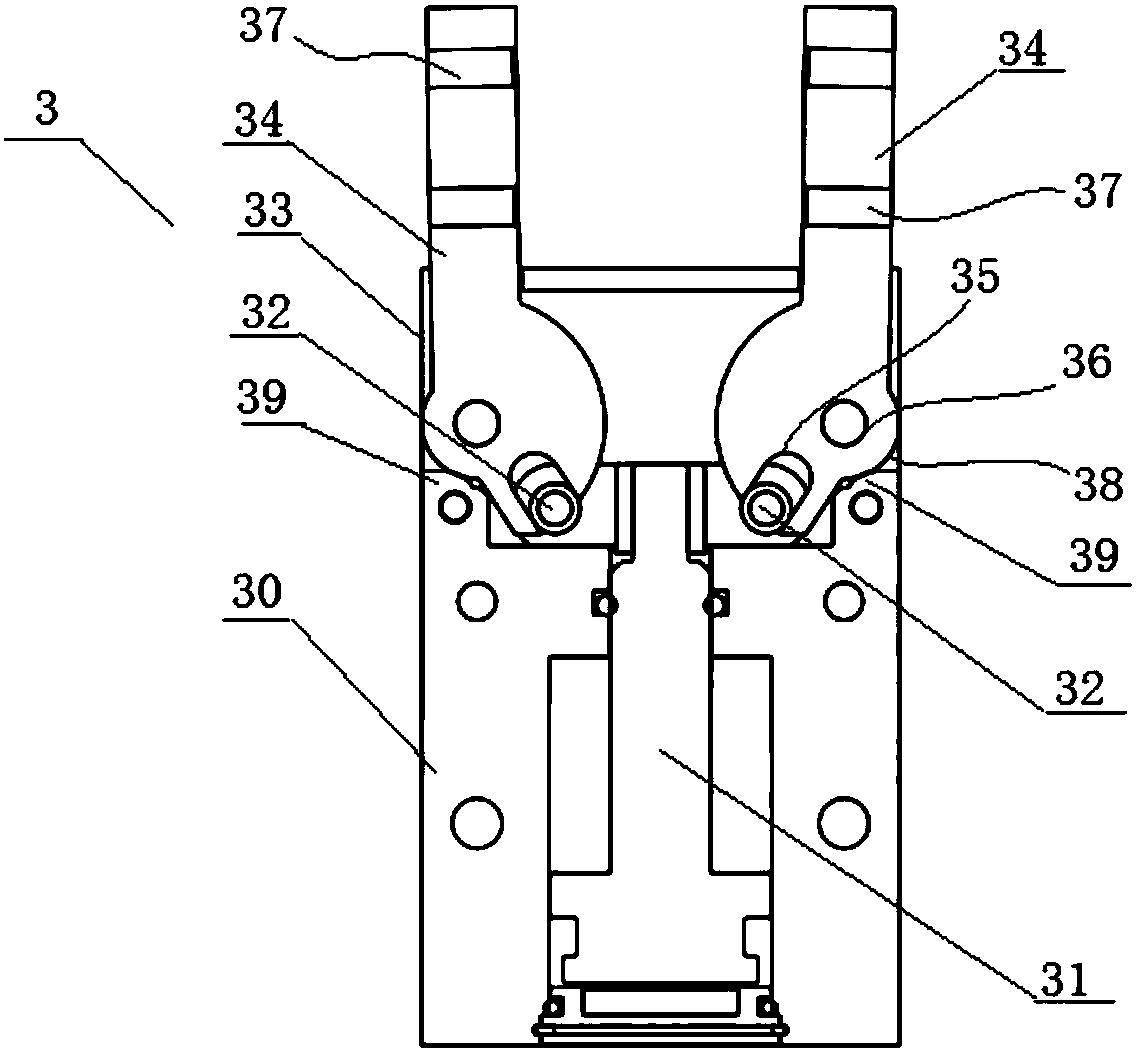

[0022] see Figure 1 to Figure 6 The top clamping device for a shaft workpiece shown includes a stepped disc seat 1 fixedly connected to the headstock or tailstock of the machine tool, and a top 2 protruding from the center of the disc seat. Its essential features are: A hydraulic overturn clamping mechanism is fixedly connected to the edge of the disc seat; the hydraulic overturn clamping mechanism includes two sets of hydraulic drive components 3 with the same structure and symmetrically arranged on the edge of the disc seat, and two pairs of The overturn clamping member 4 connected by two sets of hydraulic drive members.

[0023] One set of top clamping device of the hydraulic flip clamping mechanism is installed on the spindle box of the machine tool, and the other set of top clamping device is installed on the tailstock of the machine tool, which can not only cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com