Wide-range adjustment circular instrument maintenance device

A large-scale, circular technology, applied in the direction of grinding machines, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of low efficiency of instrument surface polishing and waxing maintenance operations, uneven results, etc., to achieve convenient polishing and grinding operations, Effect of improving clamping stability and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

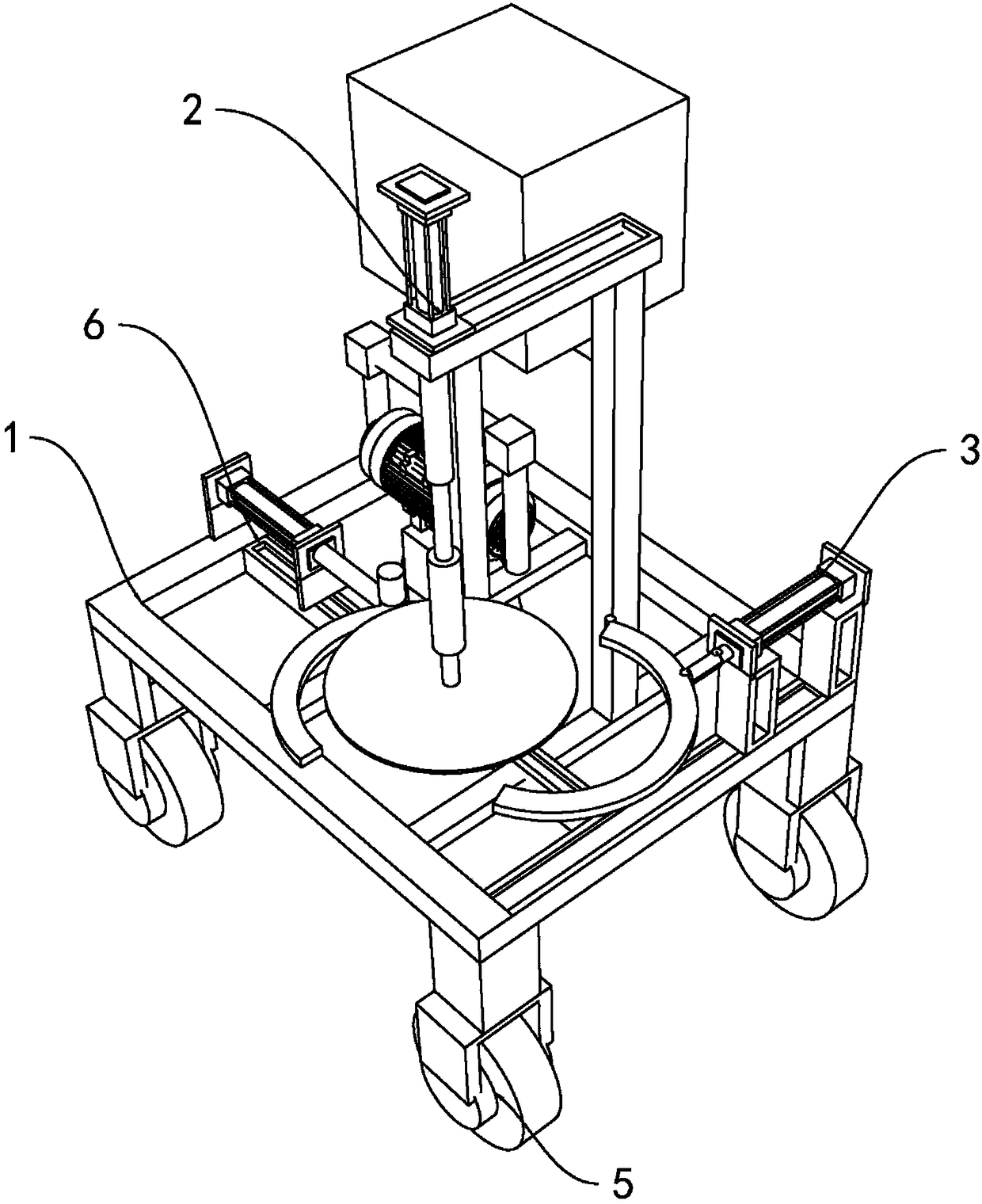

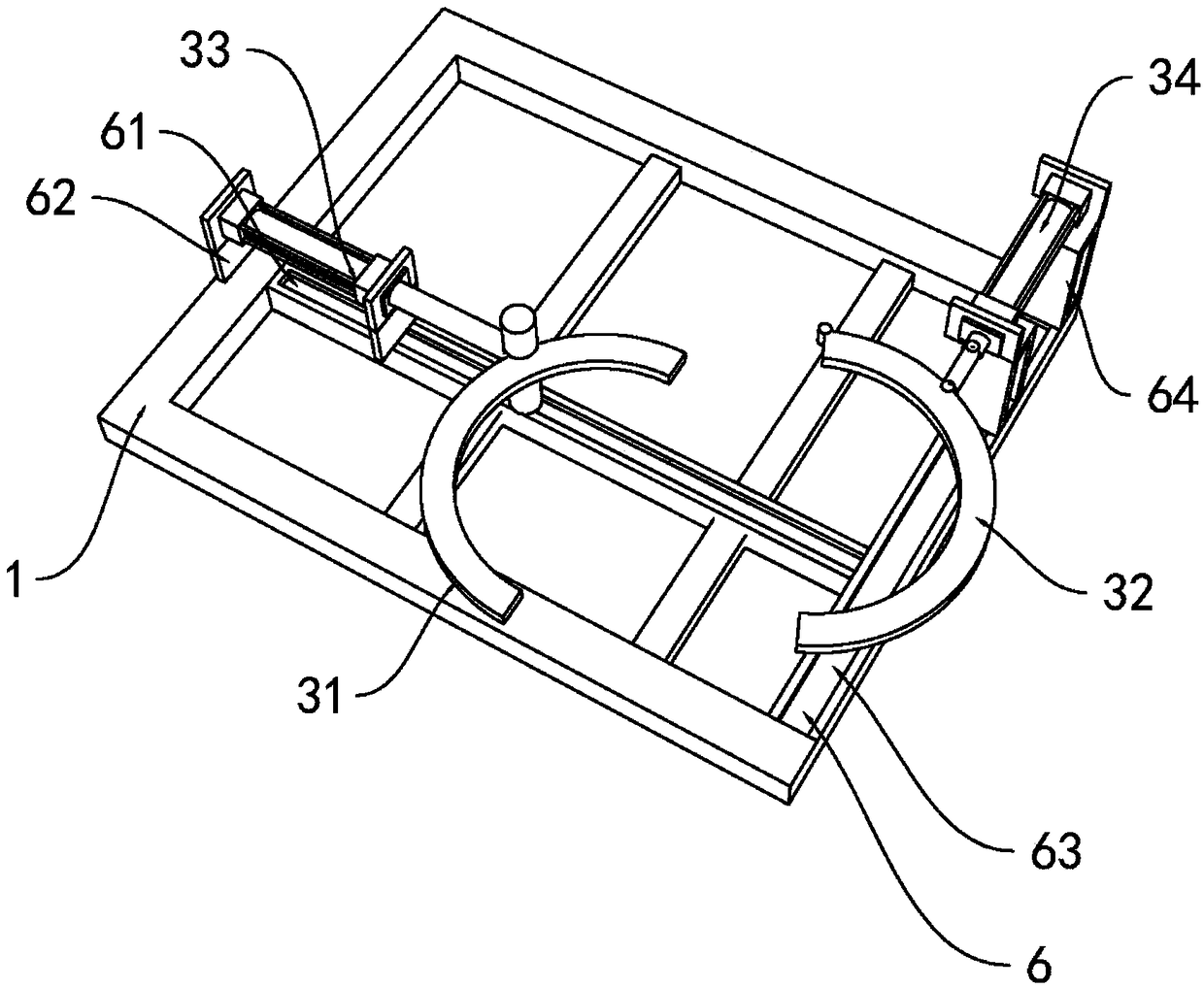

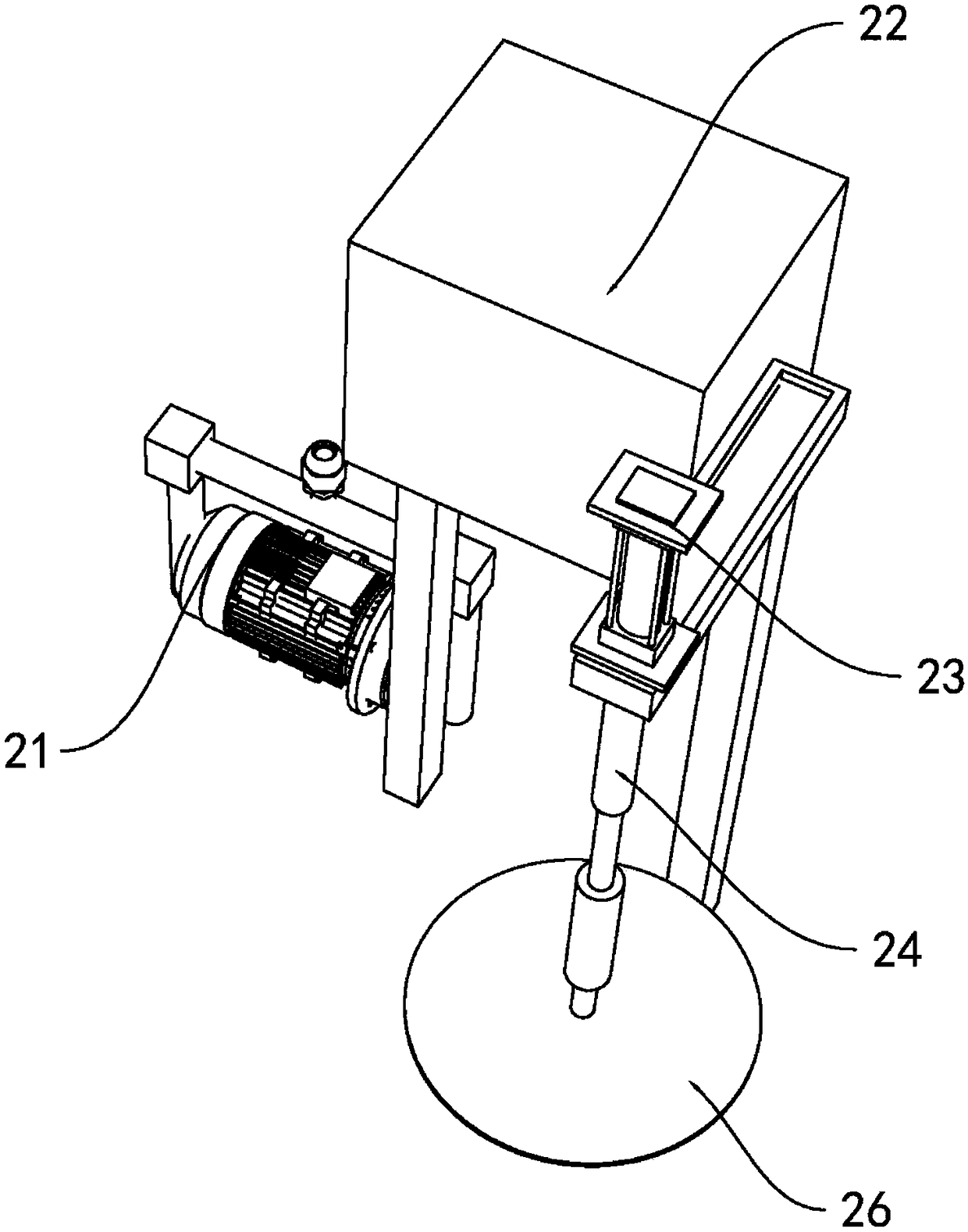

[0027] As shown in the figure, this embodiment provides a large-scale adjustment circular instrument maintenance device, including a counterweight base 1, a grinding and polishing integrated mechanism 2 for grinding and polishing the surface of the instrument, a clamping mechanism 3 for clamping the instrument, The folding wheel set 5 for providing displacement, the spacing adjustment mechanism 6 for adjusting the position, the grinding and polishing integrated mechanism 2 is installed on the counterweight base 1 through the bracket, the clamping mechanism 3 is located below the grinding mechanism, and the The folding wheel set 5 is installed on the four corners of the counterweight base 1, the distance adjustment mechanism 6 is installed on the counterweight base 1, and the clamping mechanism 3 is installed above the distance adjustment mechanism 6;

[0028] The clamping mechanism 3 includes a first semicircle clamping part 31, a second semicircle clamping part 32, a first cla...

Embodiment 2

[0031] This embodiment has made the following optimizations on the basis of Embodiment 1: As shown in the figure, this embodiment provides a large-scale adjustment circular instrument maintenance device, including a counterweight base 1, a grinding and polishing device for grinding and polishing the surface of the instrument. An integrated mechanism 2, a clamping mechanism 3 for clamping an instrument, a folding wheel set 5 for providing displacement, and a distance adjustment mechanism 6 for adjusting a position. The grinding and polishing integrated mechanism 2 is installed on the counterweight base 1 through a bracket , the clamping mechanism 3 is located below the grinding mechanism, the folding wheel set 5 is installed on the four corners of the counterweight base 1, the distance adjustment mechanism 6 is installed on the counterweight base 1, and the clamping mechanism 3 is installed on Above the distance adjustment mechanism 6;

[0032] The clamping mechanism 3 includes...

Embodiment 3

[0035] This embodiment has made the following optimizations on the basis of Embodiment 1: As shown in the figure, this embodiment provides a large-scale adjustment circular instrument maintenance device, including a counterweight base 1, a grinding and polishing device for grinding and polishing the surface of the instrument. An integrated mechanism 2, a clamping mechanism 3 for clamping an instrument, a folding wheel set 5 for providing displacement, and a distance adjustment mechanism 6 for adjusting a position. The grinding and polishing integrated mechanism 2 is installed on the counterweight base 1 through a bracket , the clamping mechanism 3 is located below the grinding mechanism, the folding wheel set 5 is installed on the four corners of the counterweight base 1, the distance adjustment mechanism 6 is installed on the counterweight base 1, and the clamping mechanism 3 is installed on Above the distance adjustment mechanism 6;

[0036] The clamping mechanism 3 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com