Stokehole automatic temperature measuring and/or sampling method of steelmaking converter molten steel

A steel-making converter and automatic technology, applied in the manufacture of converters, etc., can solve the problems of easy bending and deformation of the head, high requirements for insertion dimensional accuracy, difficult and accurate installation of casing and gun head, etc., to reduce human factors and, The effect of eliminating the interference of human factors and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] An automatic temperature measurement and / or sampling method for molten steel in a steelmaking converter. The method uses an automatic temperature measurement and sampling system in front of a steelmaking converter for separate temperature measurement or sampling, or simultaneous temperature measurement and sampling.

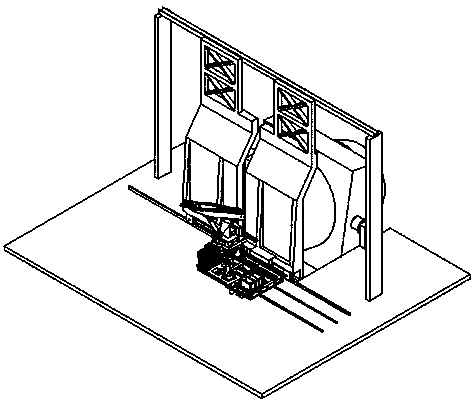

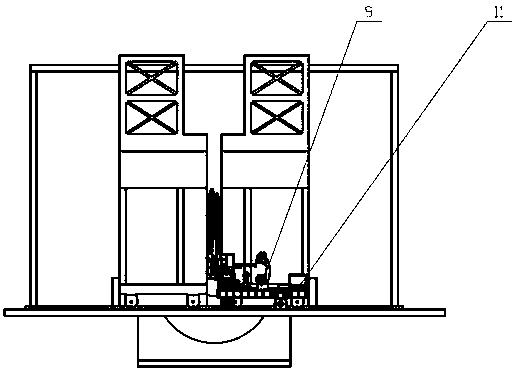

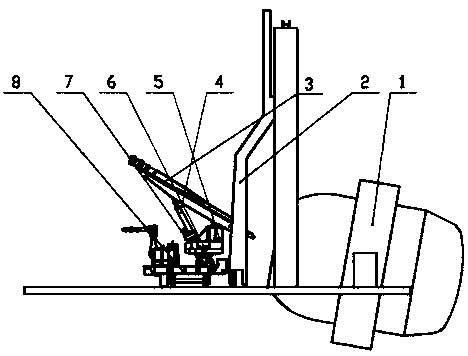

[0045] Such as Figure 1-7As shown, the automatic temperature measurement and sampling system in front of the steelmaking converter includes: an automatic temperature measurement and sampling part in front of the furnace, an automatic disassembly and assembly part of the casing, and a system electric control part.

[0046] The automatic temperature measurement and sampling part in front of the furnace is composed of a longitudinal moving device 3, an overturning device 4, an overturning safety device 5, a rotating device 6, a lateral moving device 7 and a walking trolley 8; the walking trolley 8 drives the entire system to follow the furnace The front fire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com