Method for reducing corrosion of strong oxidizing polymer degradation agent to oil well tubular column

A technology of strong oxidizing and degrading agents, which is applied in the field of reducing the corrosion of oil well tubing strings by strong oxidizing polymer degrading agents, can solve the problems of not being widely used and corrosion of oil well tubing strings, and achieves excellent corrosion inhibition performance, low cost, The effect of wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh different masses of Na 2 SiO 3 and Na 5 P 3 o 10 (both are analytically pure) to form (Si-P) composite corrosion inhibitors of different proportions, dissolve in distilled water, stir at room temperature for ten minutes, and wait for the two compounds to fully react in the aqueous solution to obtain different proportions of (Si-P) -P) Composite corrosion inhibitor solution.

[0029] Strong oxidizing polymer degrader solution: use analytically pure NaIO 4 Prepare 1% NaIO with formation water 4 solution.

[0030] The prepared (Si-P) composite corrosion inhibitor was used for corrosion protection of steel samples in strong oxidative polymer degradant solution.

[0031] 2. Compatibility of (Si-P) composite corrosion inhibitor and strong oxidizing polymer degradation agent solution

Embodiment 2

[0033] Pour 100 mL of the prepared strong oxidizing polymer degradation agent solution into a stoppered colorimetric tube, add 5% (Si-P) composite corrosion inhibitor, shake for 5 minutes and mix well. Then put the colorimetric tube into a constant temperature water bath, keep the temperature constant for 48 hours, and observe the state of the solution.

[0034] Compatibility test results show that the polymer degradation agent solution containing 5% (Si-P) composite corrosion inhibitor is transparent and clear, and there is no liquid / liquid phase and liquid / solid phase separation. It shows that the (Si-P) composite corrosion inhibitor has excellent solubility and dispersibility in the solution of strong oxidizing polymer degradation agent, reaching the first-class standard.

[0035] 3. Corrosion performance test of strong oxidizing polymer degrading agent solution

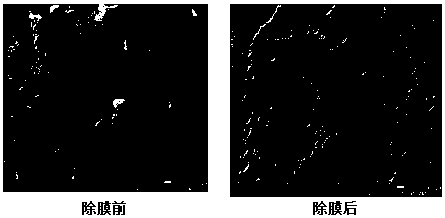

[0036] Steel sample treatment: grind the 30mm×20mm×2mm steel sample with 400#, 600#, 800# sandpaper in turn, t...

Embodiment 3

[0037]Embodiment 3: Weight loss method test

[0038] Accurately weigh the treated steel samples, suspend them in strong oxidative polymer degradant solutions with and without (Si-P) composite corrosion inhibitors, and take out the steel samples after 4 hours of immersion corrosion experiment (constant temperature 333K) The samples were washed, dried, and accurately weighed to calculate the average weight loss ΔW of the steel samples.

[0039] Corrosion rate calculation:

[0040] In the formula, ΔW is the average weight loss of the steel sample before and after the corrosion test, g; s is the surface area of the steel sample, mm 2 ; t is the corrosion test time, h; C R is the average corrosion rate of steel, g / (m 2 h).

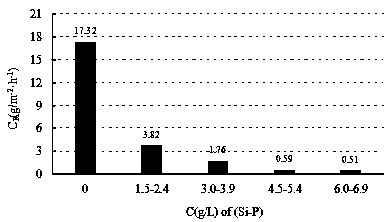

[0041] figure 1 It is the corrosion rate graph of steel in strong oxidizing polymer degradant solutions with different additions of (Si-P) composite corrosion inhibitor. The corrosion rate of steel decreases with the increase of (Si-P) composite corro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com