Magnetic revolution counter and method for determining numbers of revolutions that can be determined by means of said revolution counter

A technology of magnetic rotation and number of rotations, which is applied in the field of automobile and transmission structure, and can solve problems affecting measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] An embodiment according to the invention of a revolution counter according to the invention with a 360° switch-on, which enables an integer number of revolutions per field angle, is described below with reference to any of the figures. One-to-one read.

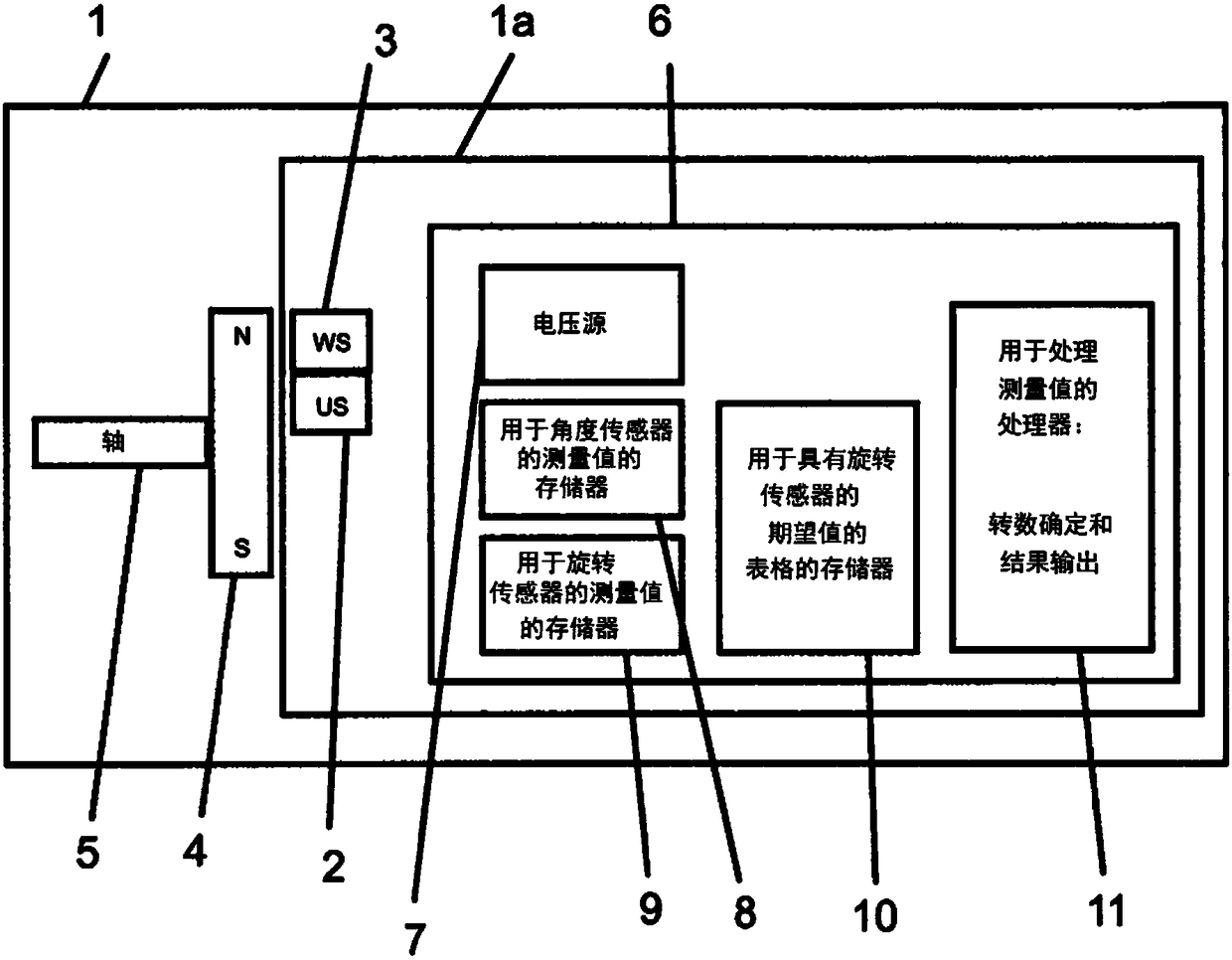

[0065] first, figure 1 The important components of such a tachometer system 1 are shown with a tachometer 1a according to the invention and a magnet system 4 with a north pole (N) and a south pole (S), the magnet system Installed on the rotating shaft 5. The tachometer 1 a consists of the following main components: rotation sensor US 2 , 360° angle sensor WS 3 and electronics 6 . Sensors 2 and 3 are installed in a stationary manner and detect the angular position and the number of revolutions of the rotating magnetic field. The electronics 6 comprise a voltage source 7 for the sensors 2 and 3 and for processing the measured values, a memory 8 for the measured values of the angle sensor 3, a memory 9 for the measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com