Wheelhead device of single round edge grinding machine for coated glass

A technology of coated glass and edging machine, which is applied in the direction of grinding/polishing safety devices, grinding heads, and parts of grinding machine tools, etc. It can solve the problems of affecting the life of grinding head components, low practicability, and polluting the coating layer, etc., to achieve Extend the life of the grinding wheel, enhance the grinding effect, and improve the practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0038] The following is attached figure 1 to attach Figure 16 Specific embodiments of the present invention will be described in detail. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

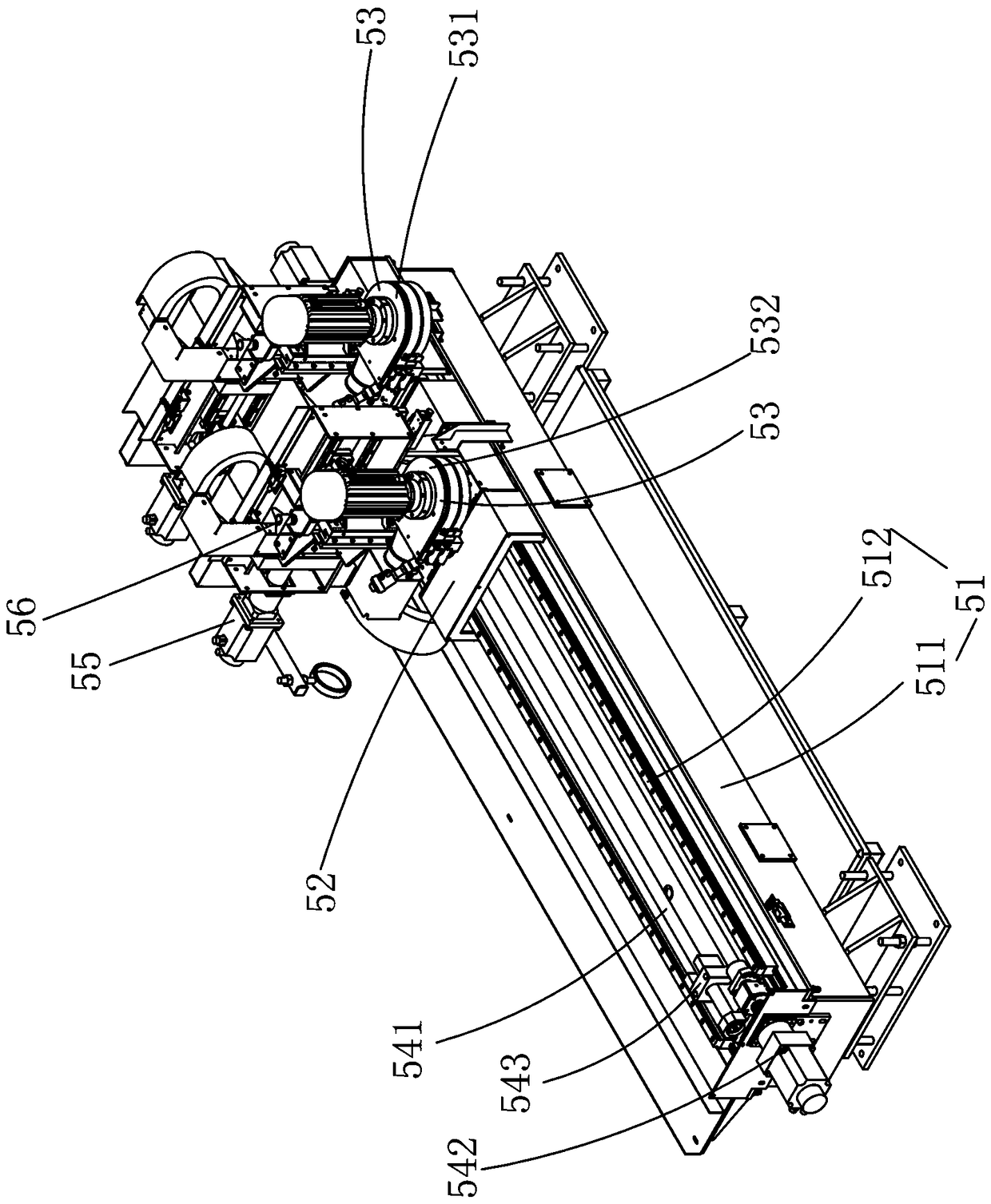

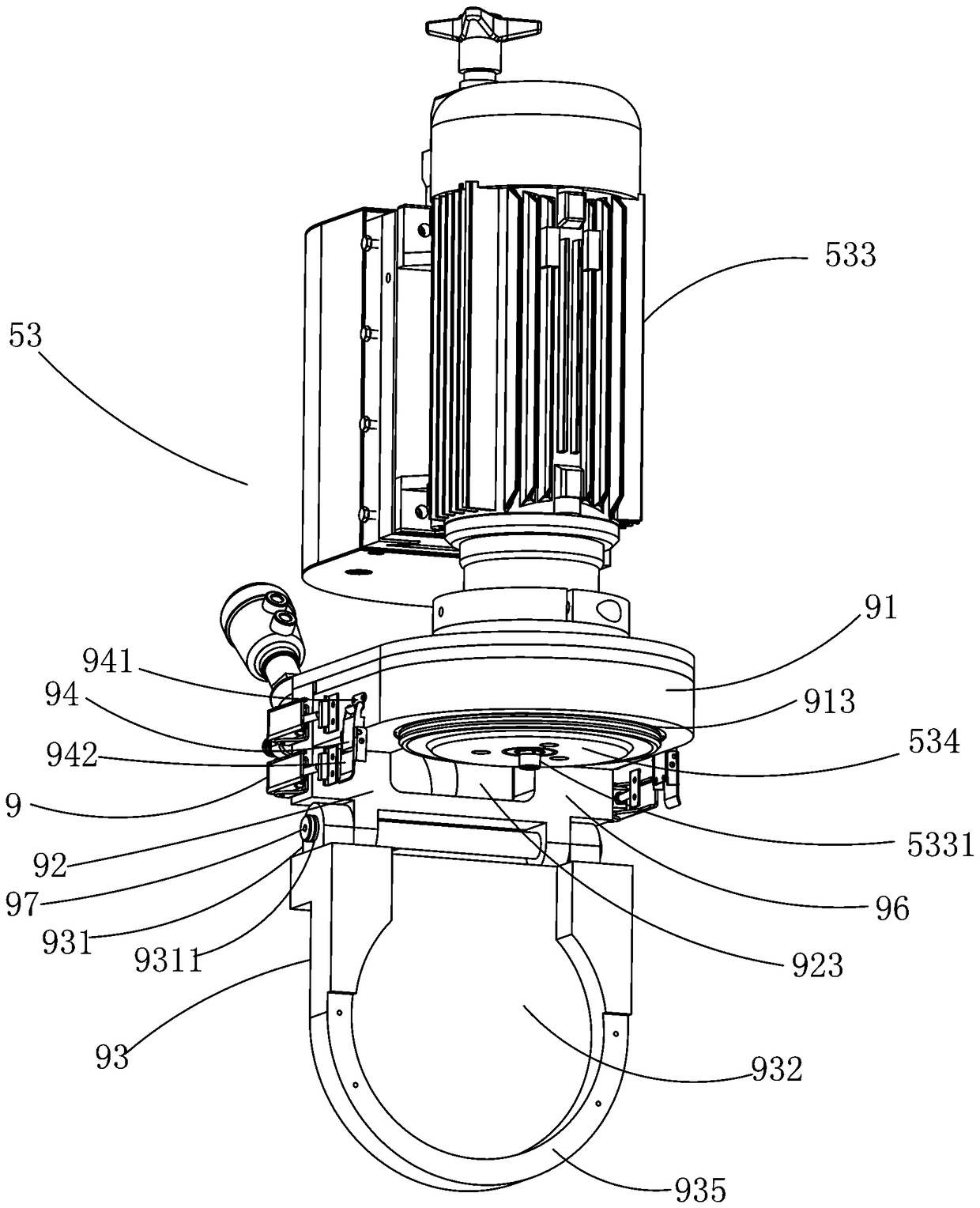

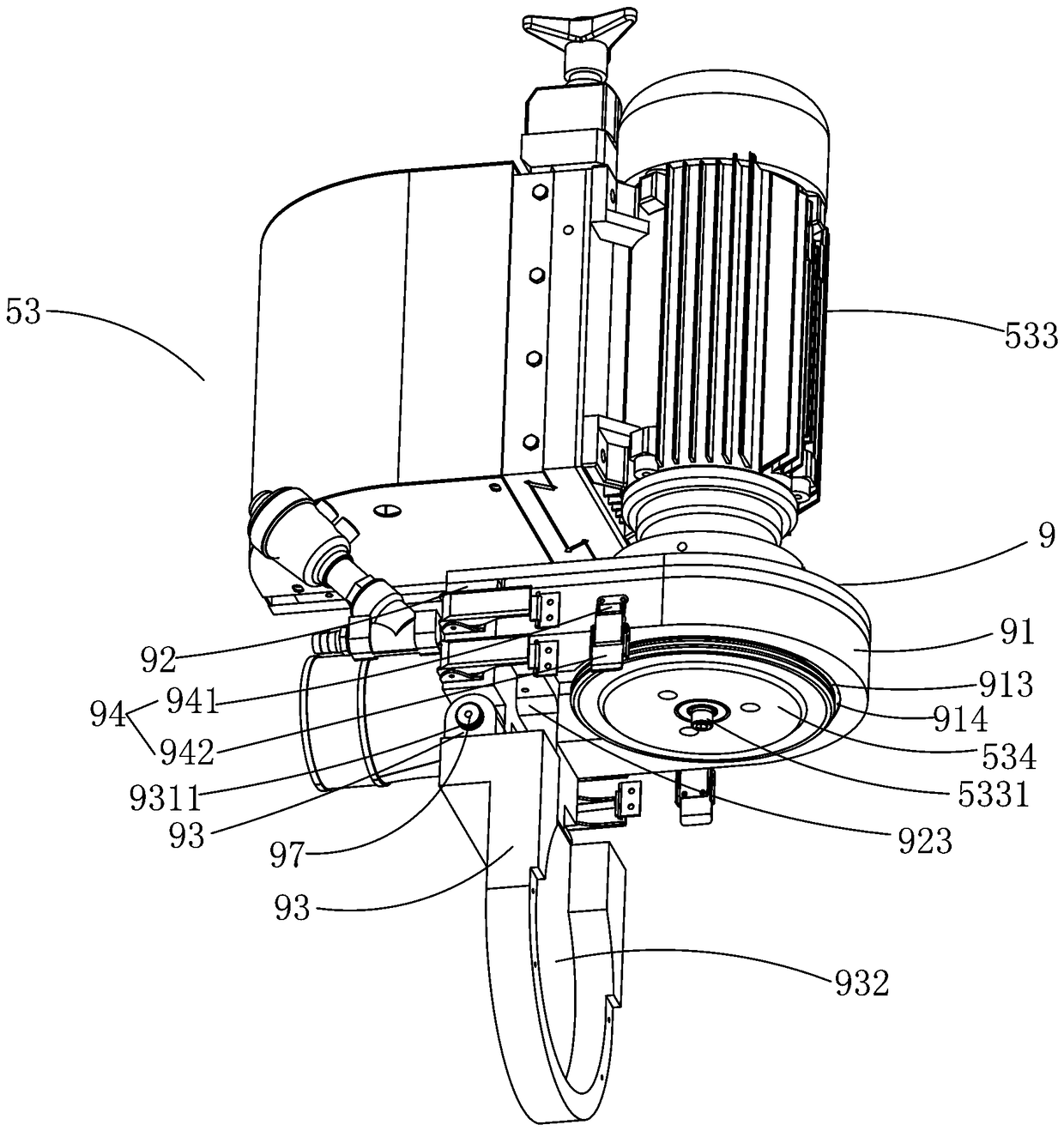

[0039] combine Figure 7 to Figure 9 As shown, a single round edge edging machine for coated glass includes a glass processing platform 1, a glass input device 11 for inputting glass is provided at the entrance of the glass processing platform 1, and a useful glass processing platform 1 is provided at the exit of the glass processing platform 1. On the glass output device 12 for outputting glass, the glass processing platform 1 is provided with a glass buffer conveying device 2 for lifting and moving the glass, a glass correction d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap