Hydrophobic material, inner-layer hydrophobic tube and preparation method for inner-layer hydrophobic tube

A technology of hydrophobic pipe and inner layer, applied to the field of inner layer hydrophobic pipe and its preparation, can solve the problems of no practical significance, high cost, cumbersome preparation process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A kind of inner layer hydrophobic pipe, its preparation method is described as follows:

[0054] 1) Prepare inner layer pellets:

[0055] Its raw materials are introduced as follows:

[0056] Polyolefin (grade 4406C, Sinopec Maoming Petrochemical), low surface energy modifier (polytetrafluoroethylene powder grade L-5, Japan Daikin Industry Co., Ltd.), compatibilizer (PE-g-MAH grade is Yi CM5804), nanoparticles (nano-ZnO, particle size 0.1-1.5μm, Shijiazhuang Dayou Zinc Industry Co., Ltd.), the selected glacial acetic acid, stearic acid, and absolute ethanol are all industrial grades (Nanhai Senhe Chemical Trading Co., Ltd. supply);

[0057] Its formula consists of:

[0058] Polyolefin: low surface energy modifier: compatibilizer: the mass ratio of nanoparticle=100:10:5:3, put these components into high-speed mixer, rotating speed 200rpm, put into twin-screw extruder to extrude after stirring for 15min For granulation, the temperature range is 150-220° C., and the ro...

Embodiment 2-6

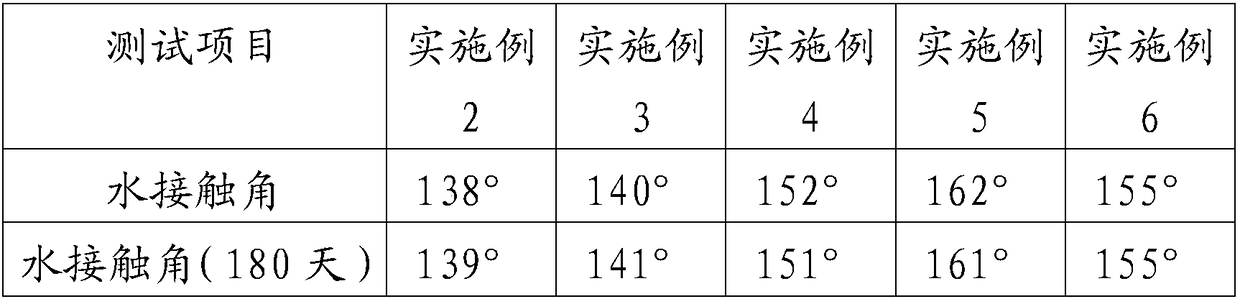

[0069] In order to verify the impact of the concentration of glacial acetic acid on the superhydrophobic properties of the inner wall of the pipe, Example 2-6 adopts the same preparation method as in Example 1 to prepare composite pipes, the only difference being that the glacial acetic acid solution used in Example 2-6 The mass concentrations are respectively 5%, 15%, 20%, 25%, 40%, respectively. The contact angles of the inner walls of the composite pipes obtained in Examples 2-6 were measured respectively.

[0070] Table 2 The results of the contact angle test on the inner wall of the pipe in Examples 2-6

[0071]

[0072] Can find out in conjunction with table 2, when the mass concentration of glacial acetic acid solution reaches 20-40%, its hydrophobicity of the product made is better, has formed the superhydrophobic surface that contact angle is greater than 150 °, and the mass concentration of glacial acetic acid solution is A superhydrophobic surface with better pe...

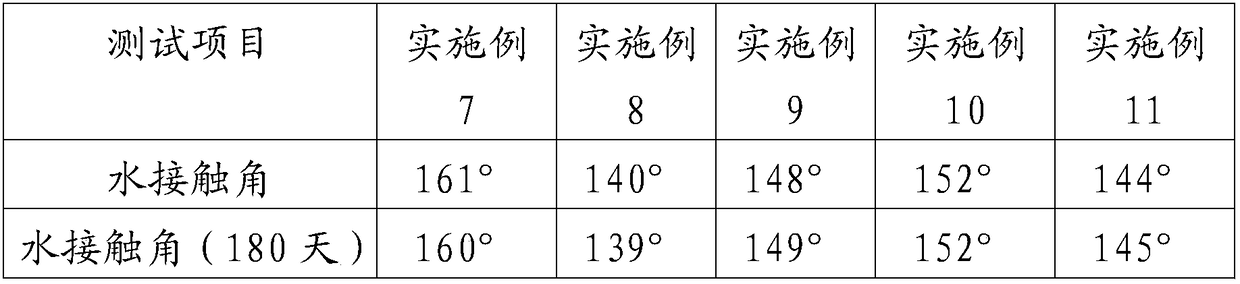

Embodiment 7

[0074] A kind of inner layer super-hydrophobic pipe material, its preparation method is described as follows:

[0075] 1) Prepare inner layer pellets:

[0076] Its raw materials are introduced as follows:

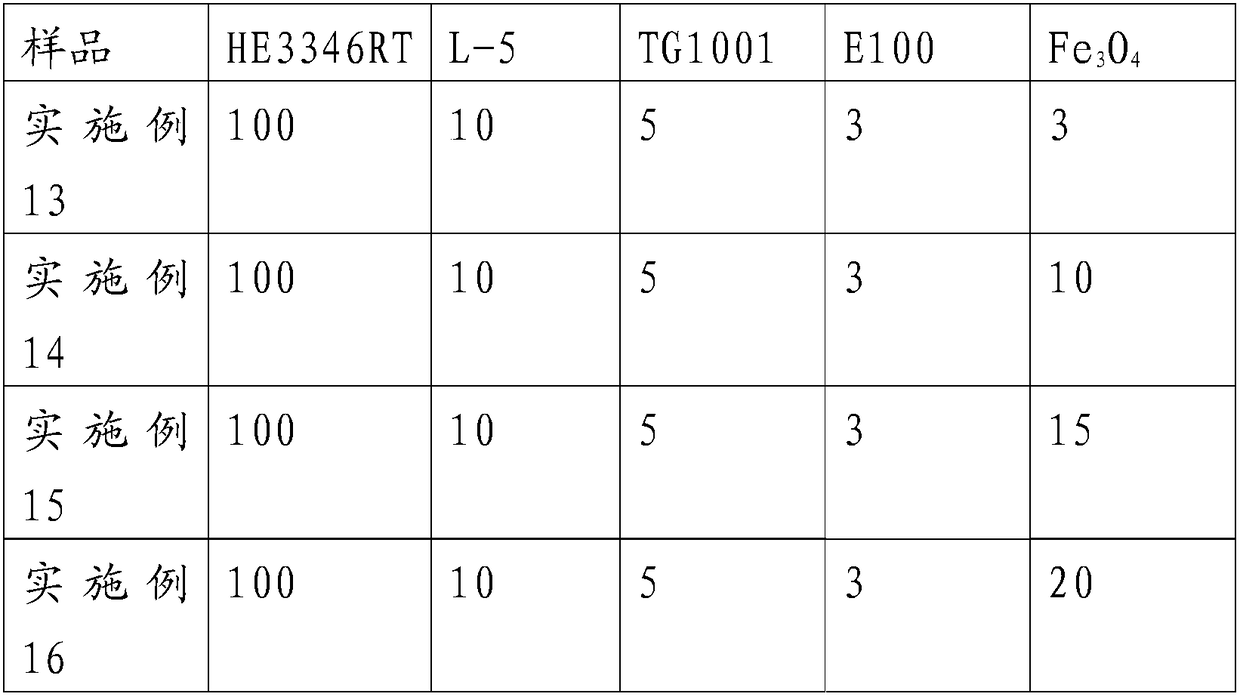

[0077] Polyolefin (grade HE3346RT, Borealis), low surface energy modifier (polytetrafluoroethylene powder grade L-5, Japan Daikin Industry Co., Ltd.), low surface energy modifier (perfluoroalkyl functional group olefins TG001, Japan Daikin Industry Co., Ltd.), compatibilizer (PE-g-MAH brand is DuPont E100), nanoparticles (nano-alumina, particle size is 0.05-2μm, Guangzhou Xinxi Chemical Industry), selected glacial acetic acid , stearic acid, and absolute ethanol are all industrial grades (provided by Nanhaisenhe Chemical Trading Company);

[0078] Wherein the formula consists of:

[0079] Polyolefin HE3346RT: Low surface energy modifier L-5: Low surface energy modifier TG1001: Compatibilizer E100: Nanoparticle Al 2 o 3 =100:10:5:3:5, put these components into a high-sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com