High chroma and high brightness pearlescent pigment and preparation method thereof

A pearlescent pigment and flaky technology, which is applied in the direction of inorganic pigment treatment, chemical instruments and methods, fibrous fillers, etc., can solve the problems of technical difficulty and limited raw materials, and achieve simple process, dense coating, excellent chroma and The effect of brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

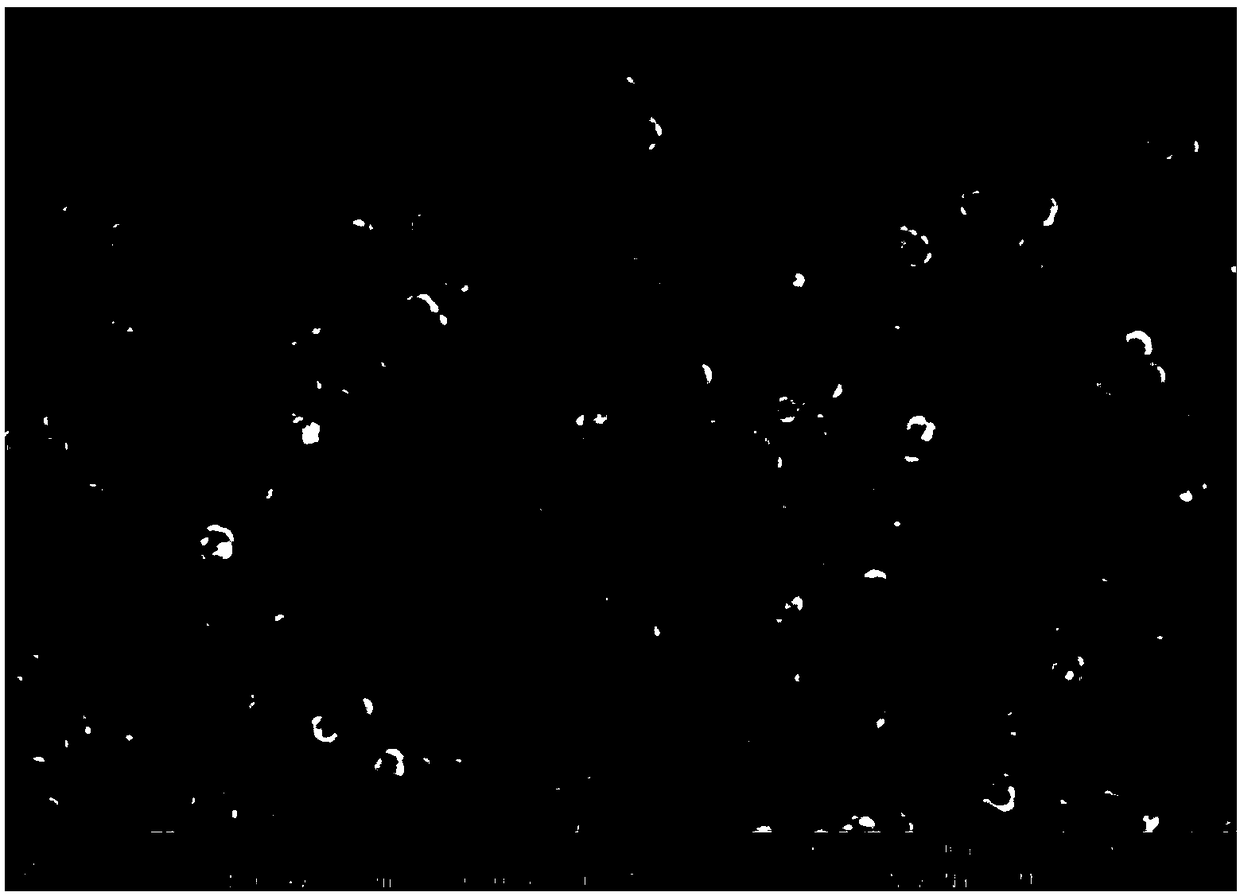

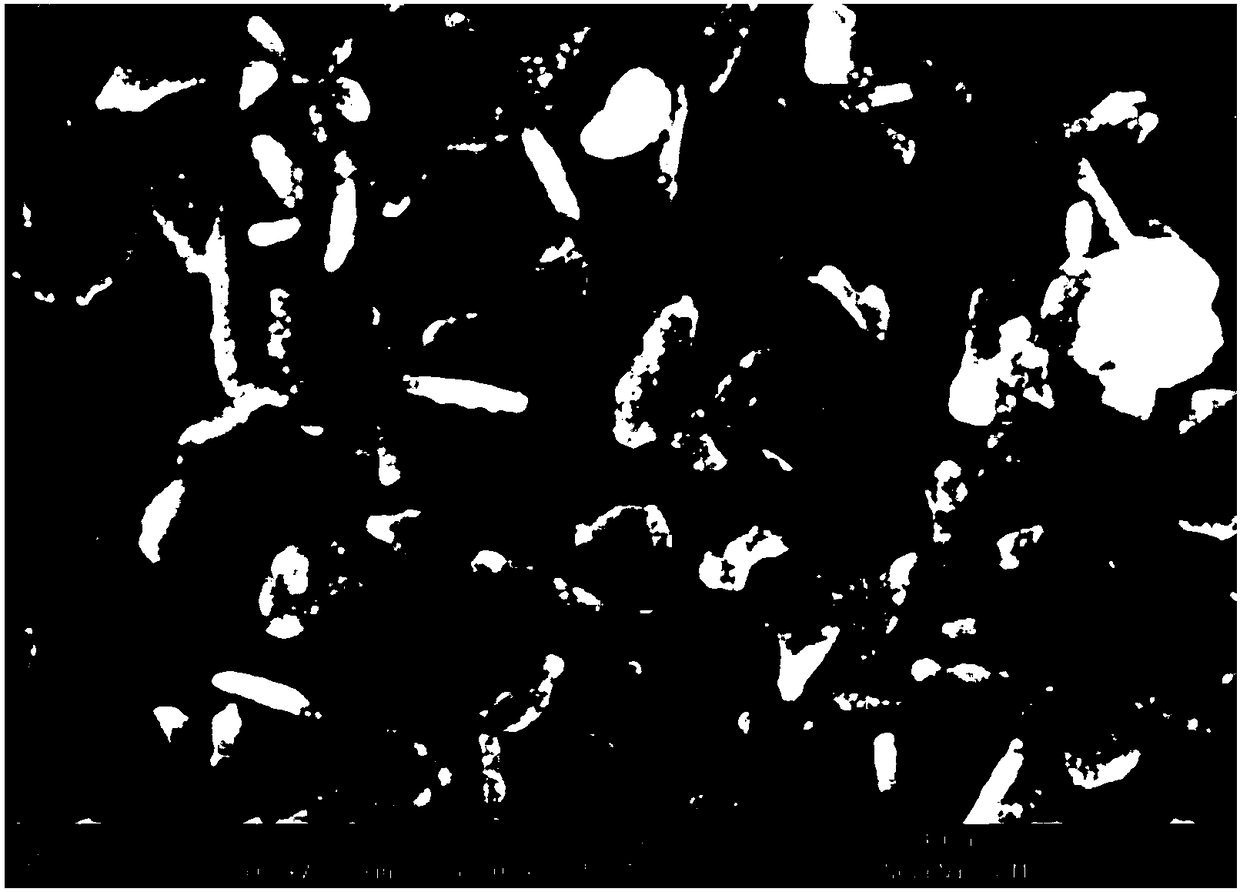

Image

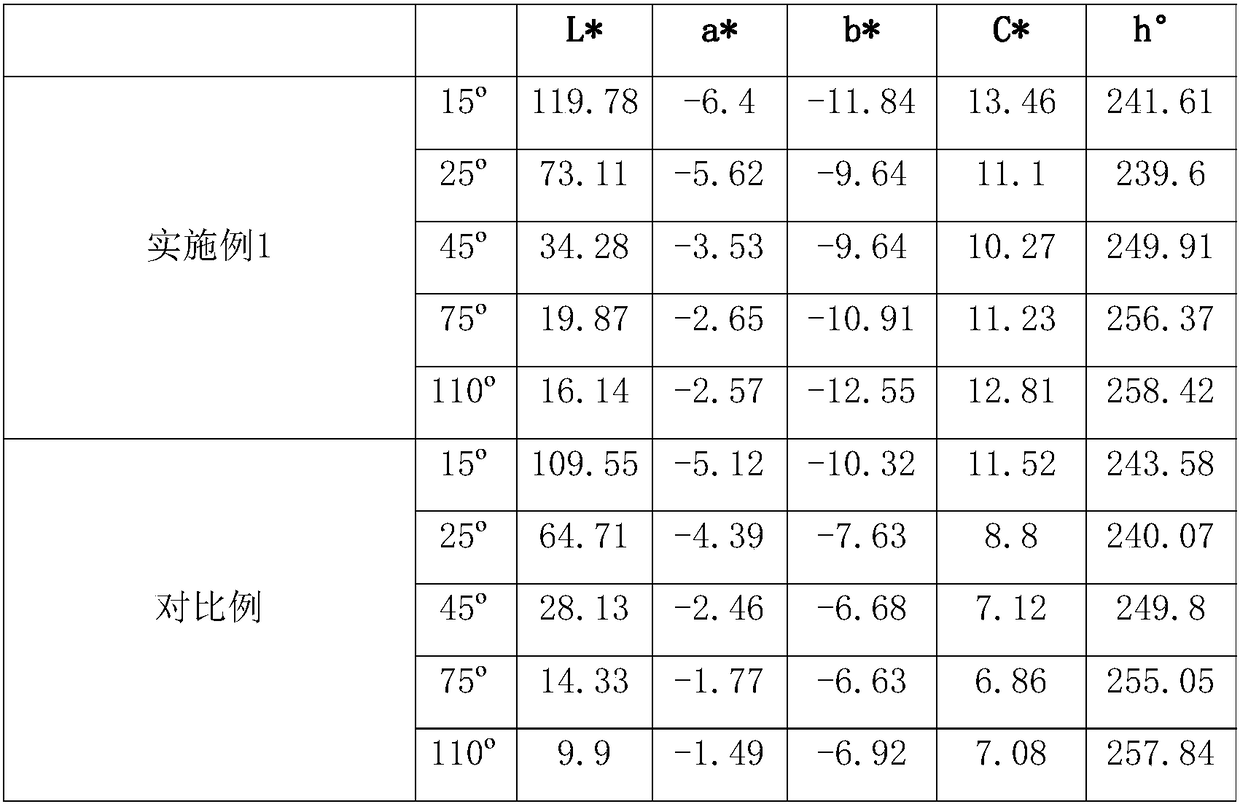

Examples

Embodiment 1

[0026] Weigh 100g of mica with a particle size of 10-60μm and a diameter-to-thickness ratio of ≥60, put it in a 5L beaker, add 2000mL of deionized water, add 0.5% of crystal guiding agent polyvinylpyrrolidone, put it in a water bath, and Stir at a rate of 200-300rps, heat up to 60-70°C, adjust the pH value of the solution between 1.2-1.8, add 100mL of 2.5% tin tetrachloride aqueous solution, and maintain the pH value of the solution with 30% NaOH solution. Add half an hour, then raise the temperature to 75-85°C, adjust the pH value of the solution between 1.5-2.5, add 2mol / L titanium tetrachloride solution dropwise at a rate of 1mL / min, and maintain the solution with NaOH solution The pH value remains unchanged. After reacting for 3 to 4 hours, filter, dry the filter cake, put it into a muffle furnace, raise the temperature to 800°C at a heating rate of 10°C / min, keep it warm for 1 hour, take it out, and cool it to room temperature. The silver muscovite titanium pearlescent pi...

Embodiment 2

[0028] Weigh 100g of mica with a particle size of 10-60μm and a diameter-to-thickness ratio>50, put it in a 2L beaker, add 1500mL of deionized water, add 1% of the crystal guiding agent octadecylammonium bromide, and put it in a water bath , and stirred at a rate of 200-300rps, heated to 75-85°C, adjusted the pH value of the solution between 3-4, added dropwise 10% ferric chloride solution at a rate of 2mL / min, and added 30% Keep the pH value of the solution constant with NaOH solution, react for 5-6 hours, filter, dry the filter cake and put it in a muffle furnace, raise the temperature to 900°C at a heating rate of 10°C / min, keep it warm for 1 hour, take it out, After cooling to room temperature, a red mica iron pearlescent pigment is obtained, wherein the thickness of the flake iron oxide coated on the surface is 50nm, and the length is 120nm.

Embodiment 3

[0030] Weigh 100g of mica with a particle size of 10-60μm and a diameter-to-thickness ratio ≥ 60, put it in a 5L beaker, add 2000mL of deionized water, add 1% of the crystal guiding agent octadecyldiethanolamine, and put it in a water bath , and stir at a rate of 200-300rps, heat up to 60-70°C, adjust the pH value of the solution between 1.2-1.8, add 100mL of 2.5% tin tetrachloride aqueous solution, and maintain the pH value of the solution with 30% NaOH solution No change, the addition is completed in half an hour, then the temperature is raised to 75-85°C, the pH value of the solution is adjusted between 1.5-2.5, and 2mol / L titanium tetrachloride solution is added dropwise at a rate of 1mL / min, and NaOH The solution maintains the pH value of the solution. After reacting for 6-7 hours, adjust the pH value of the solution between 3-4, add 10% ferric chloride solution dropwise at a rate of 2mL / min, and maintain it with 30% NaOH solution. The pH value of the solution remains unc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com