Coating composition for can to be processed, method for producing can to be processed, and can to be processed

A composition and coating technology, applied in the field of cans with processing, can solve the problems of low durability, high opening torque, easy damage, etc., and achieve the effect of high scratch resistance, low opening torque, and not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

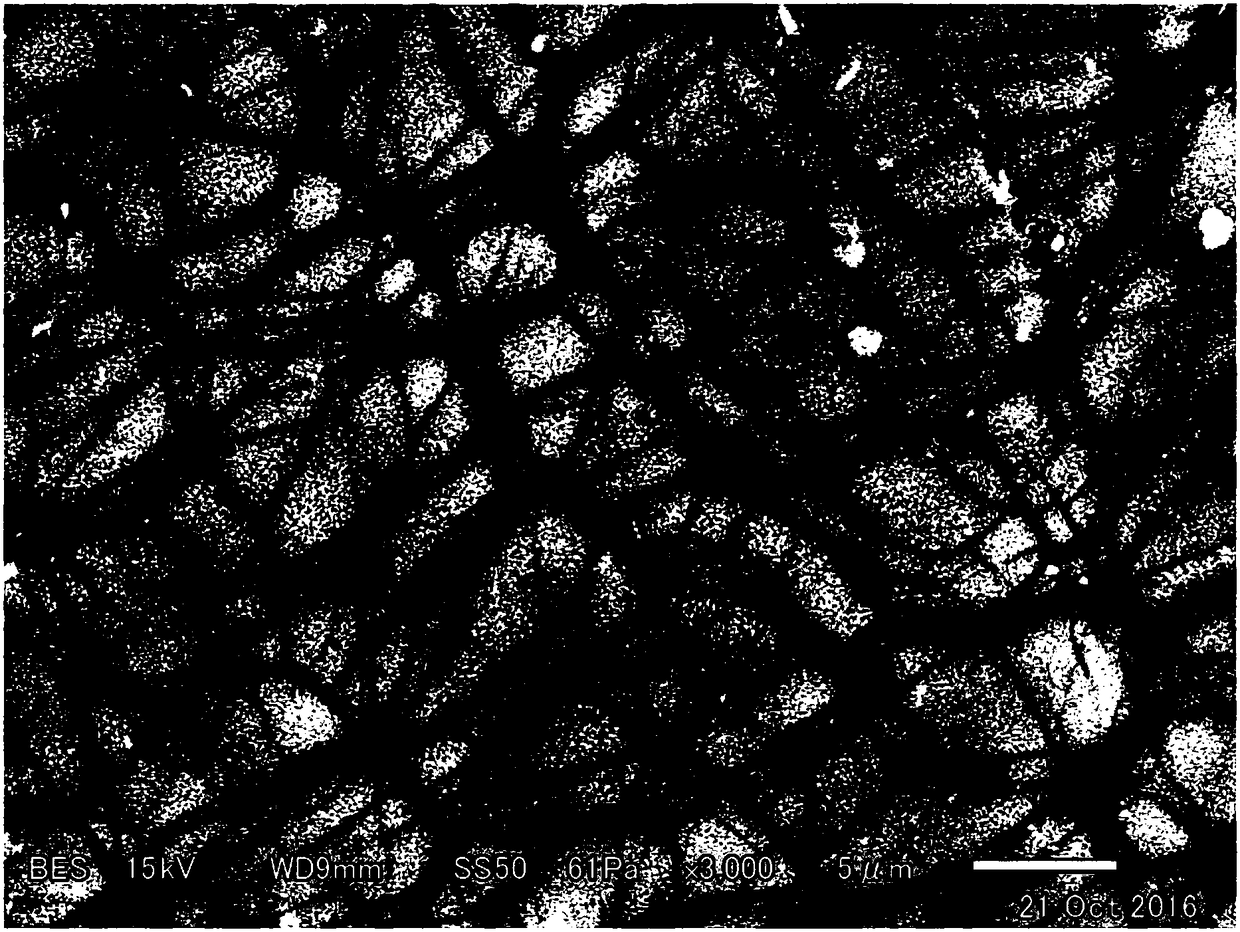

Image

Examples

preparation example Construction

[0099] [Preparation of coating composition]

[0100] As the resin component of the coating composition, polyester resins, amino resins, and epoxy resins having a Tg of 20 to 70°C (20°C, 30°C, 35°C, 40°C, 60°C, or 70°C) are used. In addition, Tg of the polyester resin was measured by the TMA method using a thermomechanical analyzer (TMA4010SE) manufactured by NETZSCH Corporation.

[0101] As the polyester resin, a combination of terephthalic acid and 2,6-naphthalene dicarboxylic acid, which are polyvalent carboxylic acids, and ethylene glycol and propylene glycol, which are polyhydric alcohols, is used. In addition, Melan series (manufactured by Hitachi Chemical Co., Ltd.) was used for the amino resin, and jER (registered trademark) Grade 1001 (manufactured by Mitsubishi Chemical Corporation) was used for the epoxy resin.

[0102] Each polyester resin having a Tg of 20 to 70° C. was mixed with an amino resin and an epoxy resin, respectively, and dissolved in a solvent to prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com