Wear-resistant lining impact and friction and wear performance evaluation testing machine

A friction and wear, evaluation test technology, applied in the direction of testing wear resistance, strength characteristics, instruments, etc., can solve the problems of long cycle, large gap between working conditions, difficult data measurement and collection, etc., to improve accuracy and evaluation efficiency, The effect of adding reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

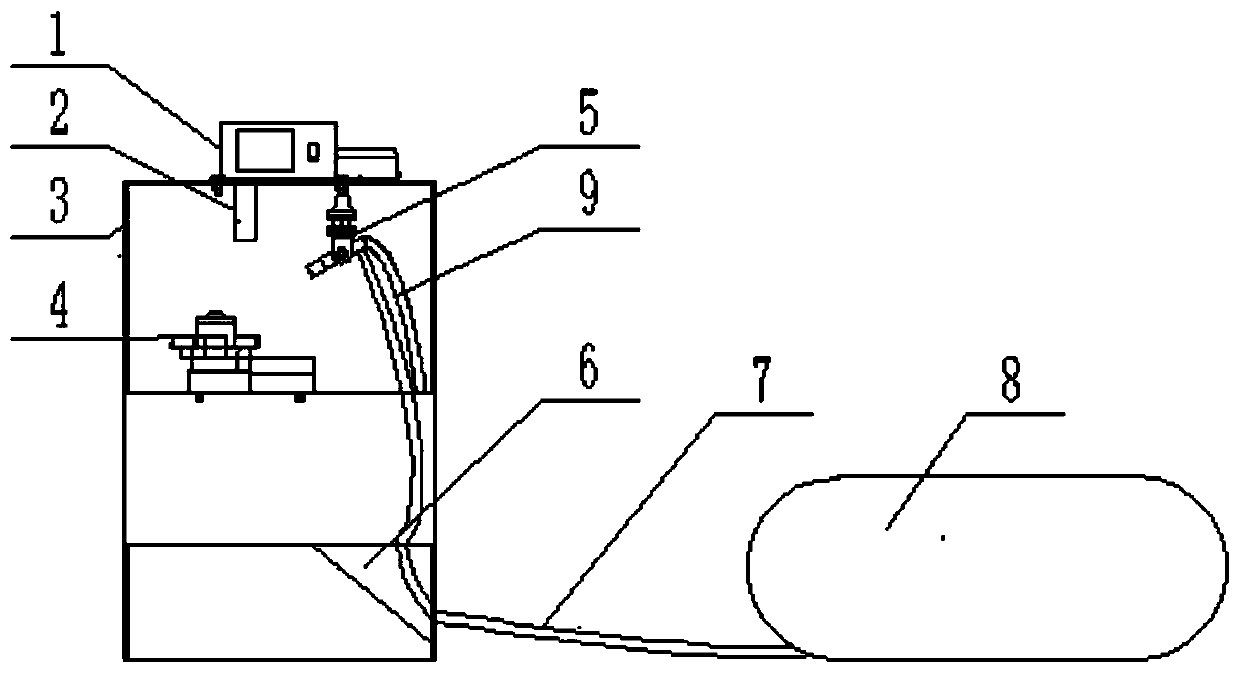

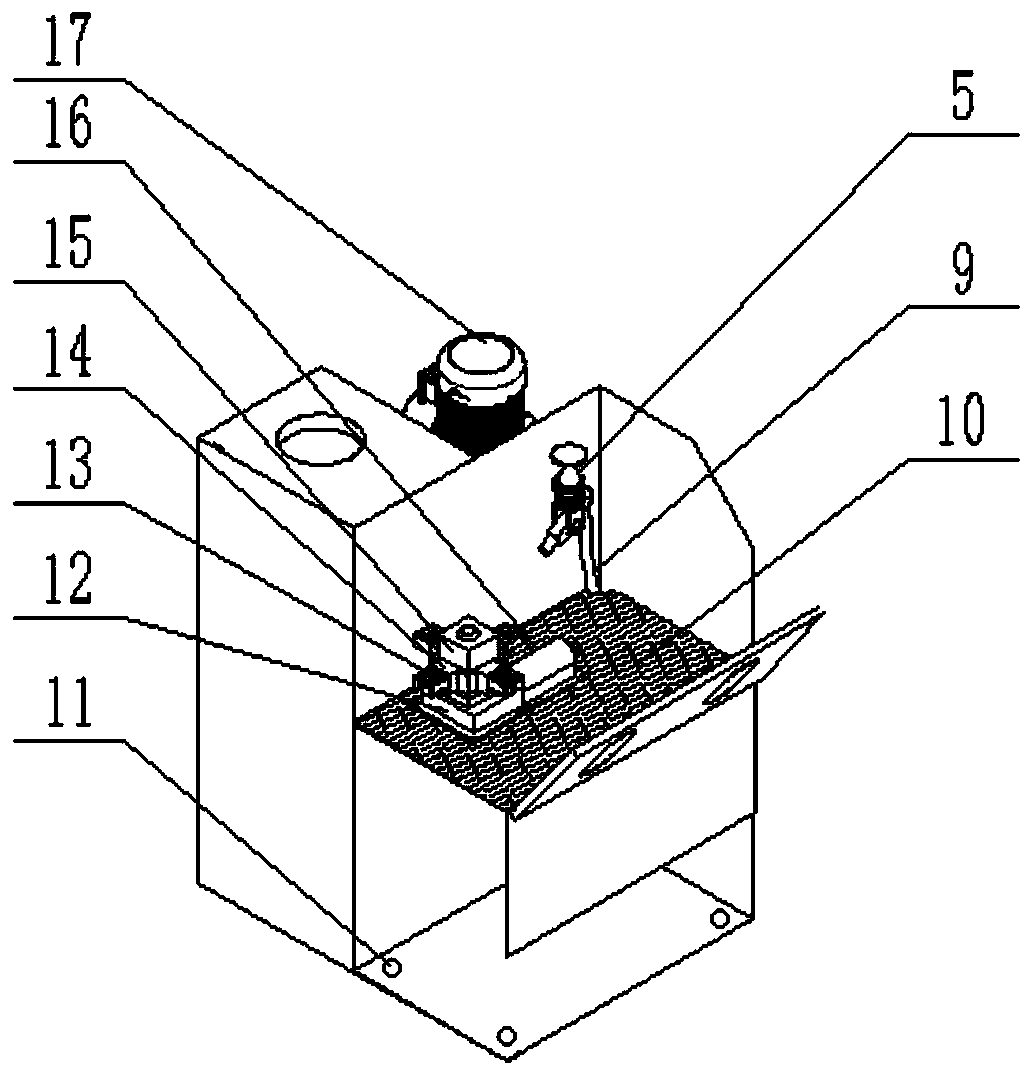

[0018] Figure 1 to Figure 7 It is an embodiment of the patent of the present invention, and the present invention realizes the automation of the whole working condition simulation by controlling the gravel erosion time of the testing machine and the rotation number of the rotary disc. The testing machine records the impact force and friction force of the gravel eroding to its surface when the workpiece is placed on the three-dimensional force sensor 13 by setting the rotary table 4 and the adjustable gravel spray gun 5, as well as the working conditions of the whole testing machine. Time flow, and then rely on data comparison and analysis to calibrate its performance.

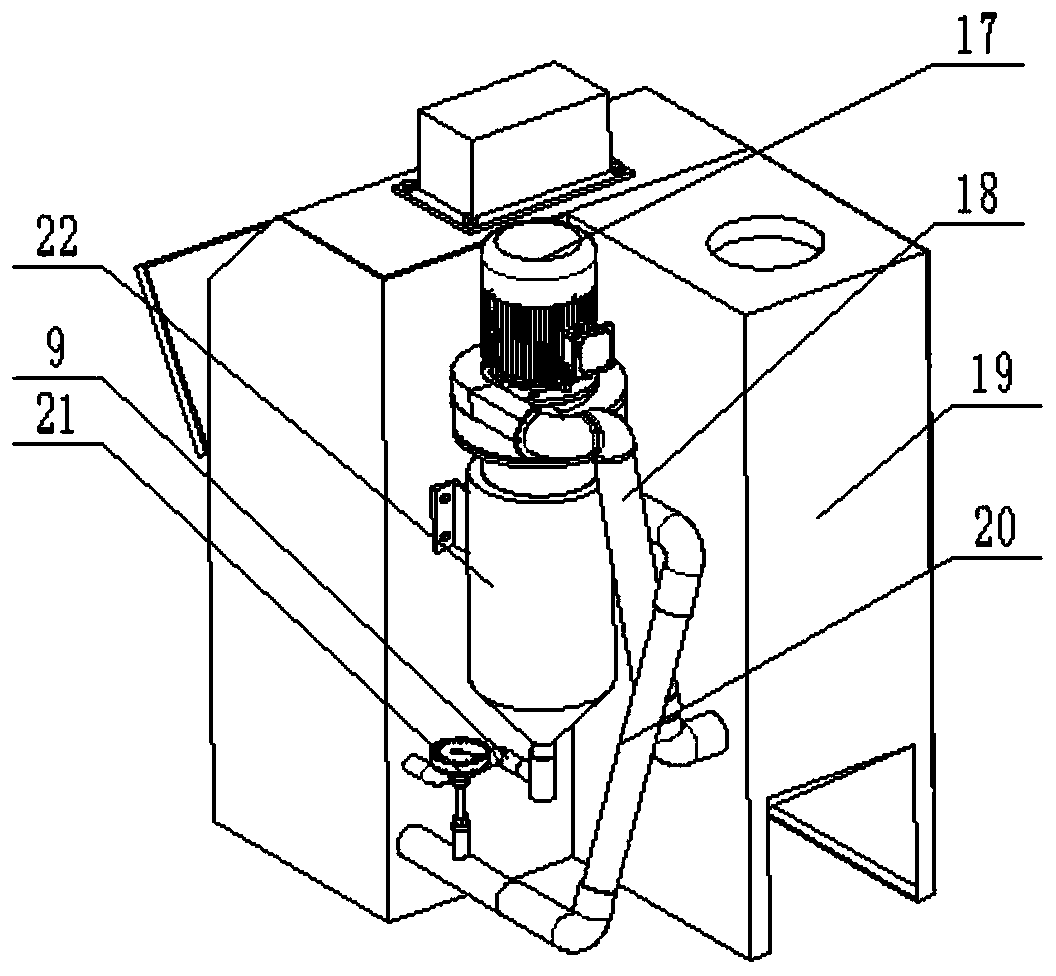

[0019] The sand blasting device consists of a gravel spray gun 5 installed on the top plate of the box body 3, a sand separation motor 17, a dust pipe 18, a dust box 19, a sand guide pipe 20, a tubular solid flow meter 21, a sand box 6, a pipeline 7 and an air pressure The machine consists of 8. The gravel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com