Method for coating graphene on tip of atomic force microscope probe

An atomic force microscope and probe tip technology, which is applied in scanning probe technology, scanning probe microscopy, measuring devices, etc., can solve the problems of low yield of atomic force microscope tips, and achieve strong practical and popularization value and yield. Improved, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

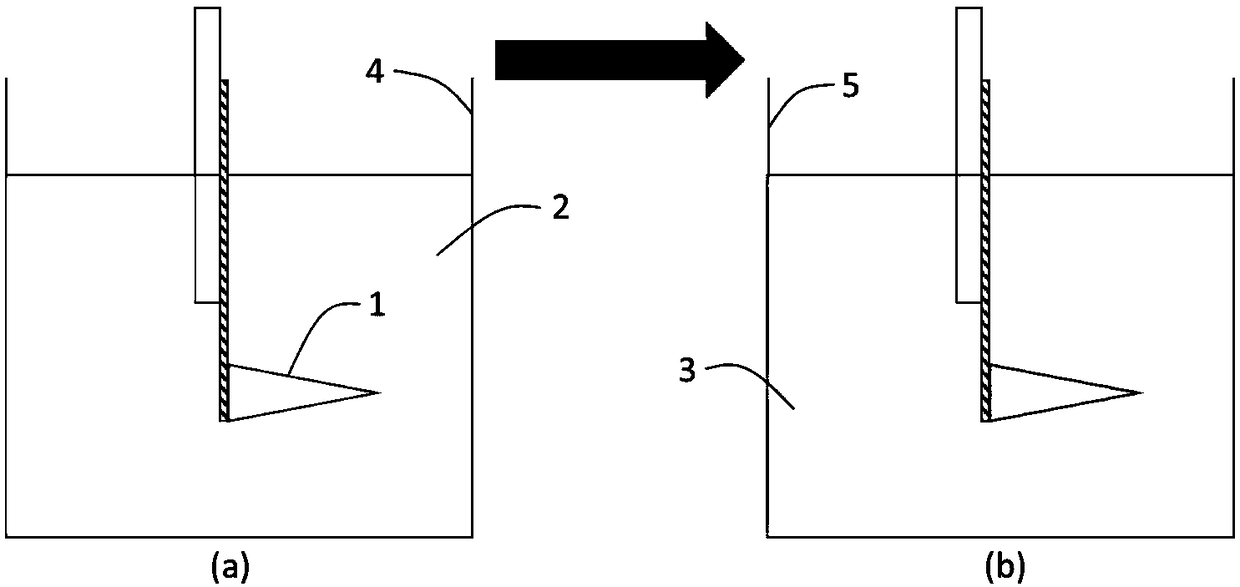

[0023] This embodiment provides a method for coating graphene on the tip of an atomic force microscope probe, and the schematic diagram of the method is as follows figure 1 shown; specifically:

[0024] (1) Poly-lysine modification: take 10 mL of poly-lysine aqueous solution 2 with a concentration of 0.001 mg / ml in the petri dish 4, and immerse the atomic force microscope probe in the poly-lysine solution 2 30 seconds, take out;

[0025] (2) Immerse graphene solution: get 10mL concentration and be that the graphene aqueous solution 3 of 1mg / ml is in petri dish 5, will immerse the atomic force microscope probe processed through step (1) in 3 for 30 seconds, take out, blow with nitrogen Do it and get it.

Embodiment 2

[0027] This embodiment provides a method for coating graphene on the probe tip of an atomic force microscope. Compared with Embodiment 1, the only difference is that the concentration of the poly-lysine aqueous solution is 0.01 mg / ml.

Embodiment 3

[0029] This embodiment provides a method for coating graphene on the tip of an atomic force microscope probe. Compared with Example 1, the only difference is that the concentration of the poly-lysine aqueous solution is 0.5mg / ml, and the The concentration of graphene solution is 2mg / ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com