Preparation method of laminated structure of photovoltaic assembly, laminated structure and photovoltaic assembly

A laminated structure and photovoltaic module technology, applied in photovoltaic power generation, coatings, electrical components, etc., can solve the problems of non-compliance with green environmental protection standards, large environmental pollution, heavy weight, etc., achieve beautiful appearance and reduce energy consumption , to ensure the effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

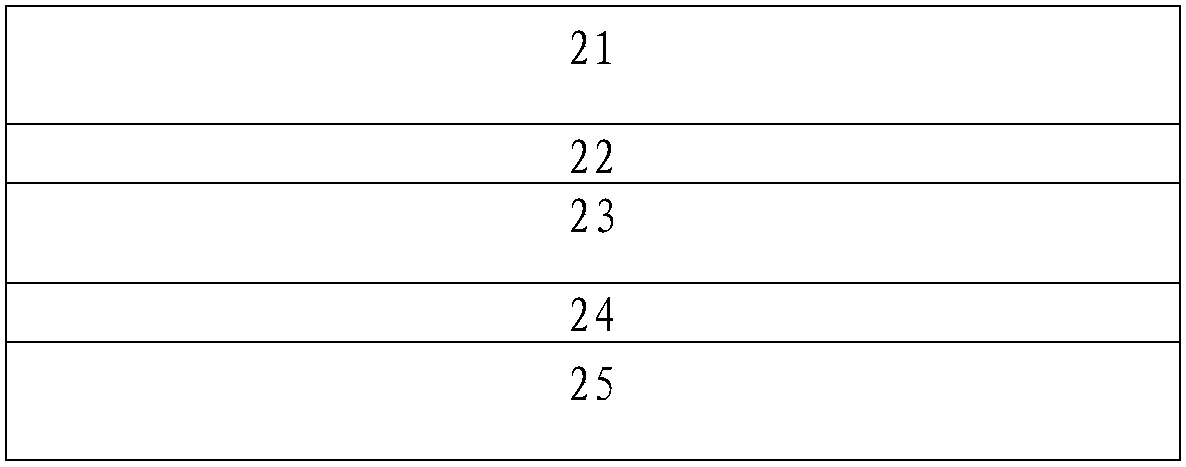

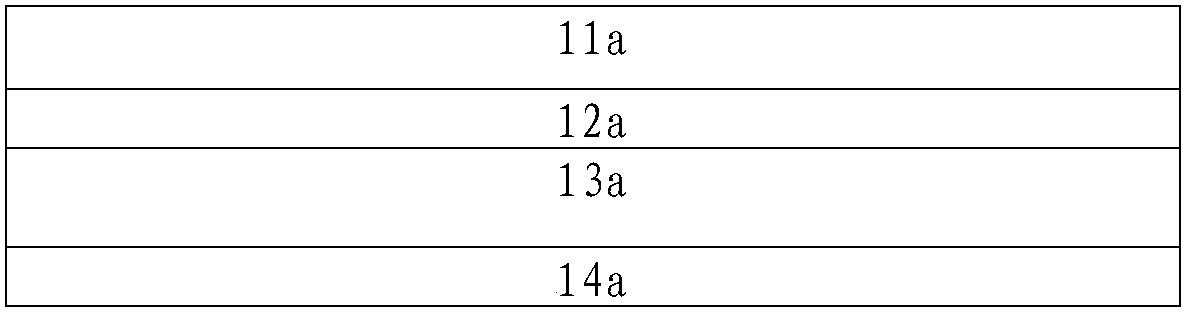

[0057] See figure 2 As shown, a laminated structure of a photovoltaic module, the laminated structure includes a first encapsulation layer 11a, a solar cell string 13a and a second encapsulation layer 14a, wherein,

[0058] Preferably, in order to further enhance weather resistance, the laminated structure includes a fluoroplastic film layer, and the fluoroplastic film layer is located above the first encapsulation layer. Preferably, in order to provide toughness protection for the solar cell strings, the laminated structure includes an encapsulation film layer, and the encapsulation film layer can be separately arranged between the first encapsulation layer and the solar cell strings or between the solar cell strings and the second encapsulation layer, It can also be arranged between the first encapsulation layer and the solar battery string and between the solar battery string and the second encapsulation layer at the same time. Further preferably, the encapsulation film l...

Embodiment 2

[0085] See image 3 As shown, in this embodiment 2, the laminated structure includes a fluoroplastic film layer 11b, a first encapsulation layer 12b, a first EVA layer 13b, a solar cell string 14b and a second encapsulation layer 15b, and the fluoroplastic film layer 11b is located at the second On the top of an encapsulation layer 12b, other technical solutions of this embodiment 2 are the same as those of the above-mentioned embodiment 1.

Embodiment 3

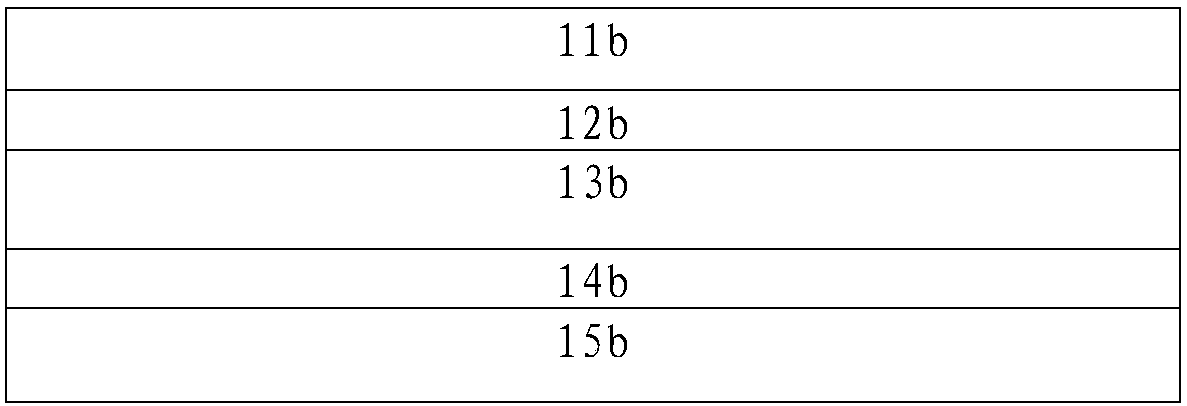

[0087] See Figure 4 As shown, in this embodiment 3, the laminated structure includes a first encapsulation layer 11c, a first EVA layer 12c, a solar cell string 13c, a second encapsulation layer 14c and a backplane layer 15c, and the backplane layer 15c is located in the second encapsulation layer Below the layer 14c, the rest of the technical solutions of the third embodiment are the same as those of the first embodiment above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight per unit area | aaaaa | aaaaa |

| Monofilament diameter | aaaaa | aaaaa |

| Monofilament diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com