RS485-based remote LED control system

A RS485, control system technology, applied in the field of lighting, can solve the problems of LED control without corresponding improvement and protection, unsuitable for long-distance control, and inability to realize remote transmission, etc., to save internal space and simple structure , Strong anti-interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

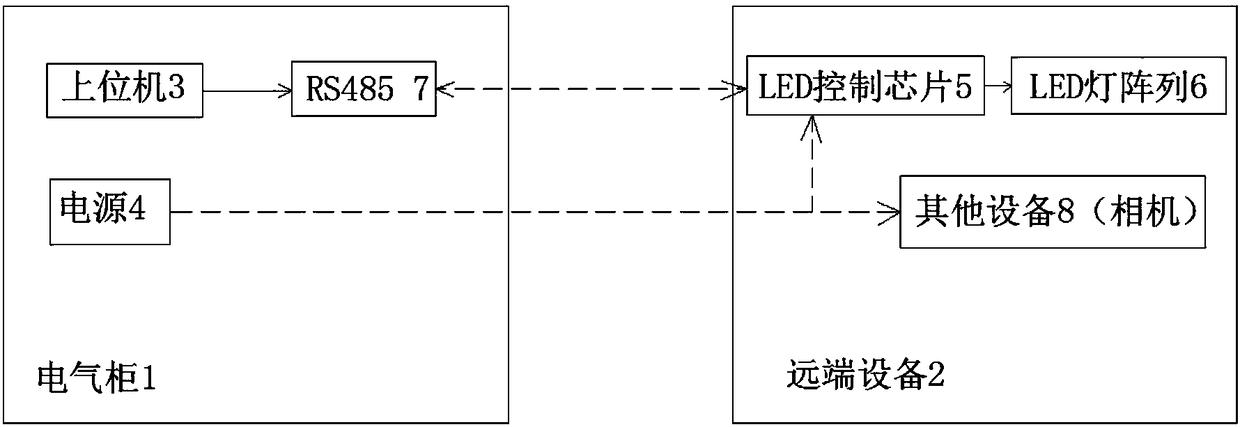

[0014] see as figure 1 As shown, the technical solution adopted in this specific embodiment is: it includes an electrical cabinet 1 and a remote device 2; wherein the electrical cabinet 1 is provided with a host computer 3, a power supply 4 and RS485 7; wherein the remote device 2 includes an LED control Chip 5 and LED light array 6; both ends of RS485 7 are connected to host computer 3 and LED control chip 5 respectively; said host computer 3 is connected to LED control chip 5 through RS485 7, and LED control chip 5 is connected to LED array 6 ; The power supply 4 is connected to the LED control chip 5 .

[0015] Further, the remote device 2 further includes other devices 8, and the power supply 4 is connected to the other devices 8; the other devices are cameras.

[0016] The working principle of this specific embodiment: through the software in the upper computer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com