Method for improving ovalbumin emulsibility through composite modifying

An ovalbumin and compound modification technology, which is applied in the field of compound modification to improve the emulsification of ovalbumin, can solve the problems of difficulty in controlling reaction conditions, residual toxic components, complicated reactions, etc. Conditionally controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

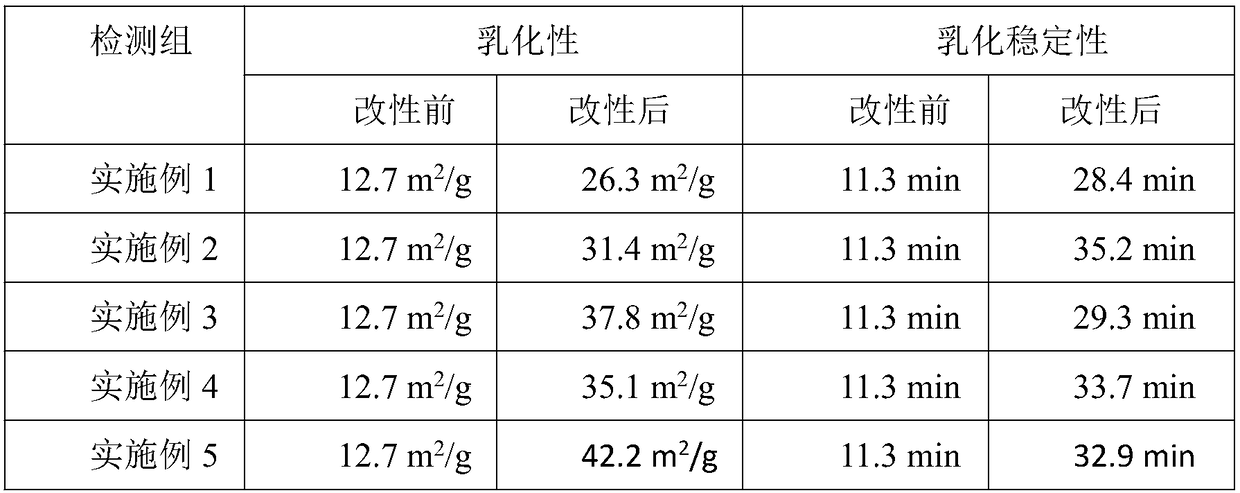

Examples

Embodiment 1

[0030] (1) Preparation of ovalbumin solution: dissolve ovalbumin in 0.01mol / L, pH 7.0 phosphate buffer solution to prepare a protein solution with a mass concentration of 0.5%, fully dissolve to obtain an ovalbumin solution;

[0031] (2) Preparation of liposomes: using the reverse evaporation method, using soybean lecithin as the wall material and cholesterol as the auxiliary wall material, the mass ratio of soybean lecithin to cholesterol is 20:1, and the preliminary liposome dispersion is prepared ;

[0032] (3) liposome particle size control: adopt micro-fluidic method to process preliminary liposome dispersion liquid, processing condition is 100MPa, circulates 8 times, obtains the liposome dispersion liquid after processing;

[0033] (4) Compounding of ovalbumin and liposomes: mix the ovalbumin solution and the treated liposome dispersion at a mass ratio of ovalbumin and soybean lecithin of 10:1, stir well until uniform, and place at 4°C for 24 hours , to obtain ovalbumin...

Embodiment 2

[0036] (1) Preparation of ovalbumin solution: dissolve ovalbumin in 0.01mol / L, pH 7.0 phosphate buffer to prepare a protein solution with a mass concentration of 1.0%, fully dissolve to obtain an ovalbumin solution;

[0037] (2) Preparation of liposomes: using the reverse evaporation method, using soybean lecithin as the wall material and cholesterol as the auxiliary wall material, the mass ratio of soybean lecithin to cholesterol is 15:1, and the preliminary liposome dispersion is prepared ;

[0038] (3) liposome particle size control: adopt micro-fluidic method to process preliminary liposome dispersion liquid, processing condition is 110MPa, circulates 6 times, obtains the liposome dispersion liquid after processing;

[0039] (4) Compounding of ovalbumin and liposomes: mix the ovalbumin solution and the treated liposome dispersion at a mass ratio of ovalbumin to soybean lecithin of 10:5, stir well until uniform, and place at 2°C for 28 hours , to obtain ovalbumin and lipos...

Embodiment 3

[0042] (1) Preparation of ovalbumin solution: dissolve ovalbumin in 0.01mol / L, pH 7.0 phosphate buffer to prepare a protein solution with a mass concentration of 1.5%, fully dissolve to obtain an ovalbumin solution;

[0043] (2) Preparation of liposomes: using the reverse evaporation method, using soybean lecithin as the wall material, and cholesterol as the auxiliary wall material, the mass ratio of soybean lecithin to cholesterol is 10:1, and the preliminary liposome dispersion is prepared ;

[0044] (3) liposome particle size control: adopt micro-fluidic method to process preliminary liposome dispersion liquid, processing condition is 125MPa, circulates 5 times, obtains the liposome dispersion liquid after processing;

[0045] (4) Compounding of ovalbumin and liposomes: mix the ovalbumin solution and the treated liposome dispersion at a mass ratio of ovalbumin and soybean lecithin of 10:10, stir well until uniform, and place at 6°C for 20 hours , to obtain ovalbumin and li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com