Preparation method of hydrophilic activated carbon

An activated carbon and hydrophilic technology, applied in the field of preparation of hydrophilic activated carbon, can solve the problems of activated carbon pore structure damage, activated carbon quality loss, etc., and achieve the effects of increased micropore content, low production cost, and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

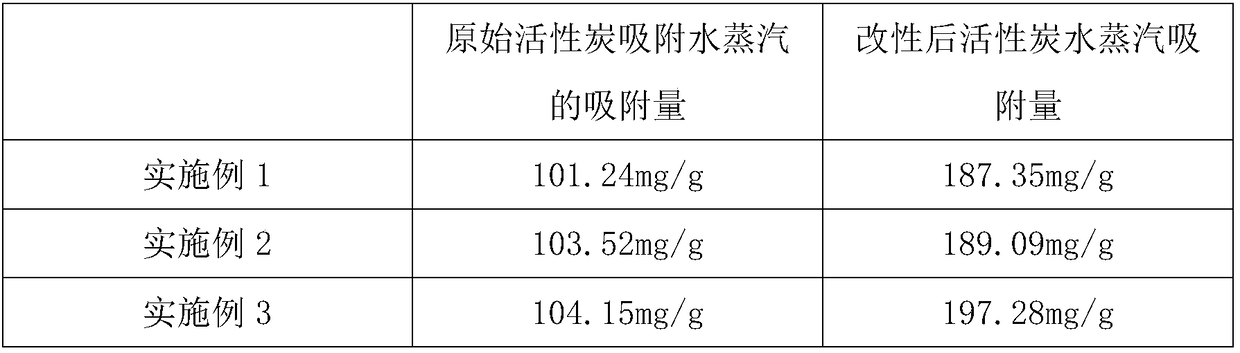

Embodiment 1

[0035] A preparation method for hydrophilic activated carbon, comprising the steps of:

[0036] Step 1, adding sodium polyacrylate to propylene glycol, mechanically stirring until completely dissolved, to obtain sodium polyacrylate alcohol solution;

[0037] Step 2, adding activated carbon to the sodium polyacrylate alcohol solution, adding a dispersant and stirring to form a stable suspension;

[0038] Step 3, sealing and stirring the suspension for 2 hours, and then distilling and reacting for 2 hours under reduced pressure to obtain prefabricated activated carbon;

[0039] Step 4, putting the prefabricated activated carbon into an oven for vacuum drying to obtain hydrophilic activated carbon.

[0040] The concentration of sodium polyacrylate in propylene glycol in the step 1 is 20g / L, and the stirring speed of the mechanical stirring is 2000r / min.

[0041] The addition of activated carbon in the step 2 is 2.5 times of the quality of sodium polyacrylate, and the addition o...

Embodiment 2

[0053] A preparation method for hydrophilic activated carbon, comprising the steps of:

[0054] Step 1, adding sodium polyacrylate to propylene glycol, mechanically stirring until completely dissolved, to obtain sodium polyacrylate alcohol solution;

[0055] Step 2, adding activated carbon to the sodium polyacrylate alcohol solution, adding a dispersant and stirring to form a stable suspension;

[0056] Step 3, sealing and stirring the suspension for 4 hours, and then distilling and reacting for 4 hours under reduced pressure to obtain prefabricated activated carbon;

[0057] Step 4, putting the prefabricated activated carbon into an oven for vacuum drying to obtain hydrophilic activated carbon.

[0058] The concentration of sodium polyacrylate in propylene glycol in the step 1 is 50g / L, and the stirring speed of the mechanical stirring is 3000r / min.

[0059] The addition of activated carbon in the step 2 is 5.5 times of the quality of sodium polyacrylate, and the addition o...

Embodiment 3

[0071] A preparation method for hydrophilic activated carbon, comprising the steps of:

[0072] Step 1, adding sodium polyacrylate to propylene glycol, mechanically stirring until completely dissolved, to obtain sodium polyacrylate alcohol solution;

[0073] Step 2, adding activated carbon to the sodium polyacrylate alcohol solution, adding a dispersant and stirring to form a stable suspension;

[0074] Step 3, sealing and stirring the suspension for 3 hours, then distilling and reacting for 3 hours under reduced pressure to obtain prefabricated activated carbon;

[0075] Step 4, putting the prefabricated activated carbon into an oven for vacuum drying to obtain hydrophilic activated carbon.

[0076] The concentration of sodium polyacrylate in propylene glycol in the step 1 is 40g / L, and the stirring speed of the mechanical stirring is 2500r / min.

[0077] The addition of activated carbon in the step 2 is 4.5 times of the quality of sodium polyacrylate, and the addition of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com