Semi-automatic glasses rubber frame machining machine

A glue frame machine and semi-automatic technology, which is applied in the direction of metal processing machinery parts, metal processing equipment, workpieces, etc., can solve the problems of low processing efficiency, time-consuming and labor-intensive, and heavy labor, so as to improve production efficiency, reduce quantity, and reduce labor. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

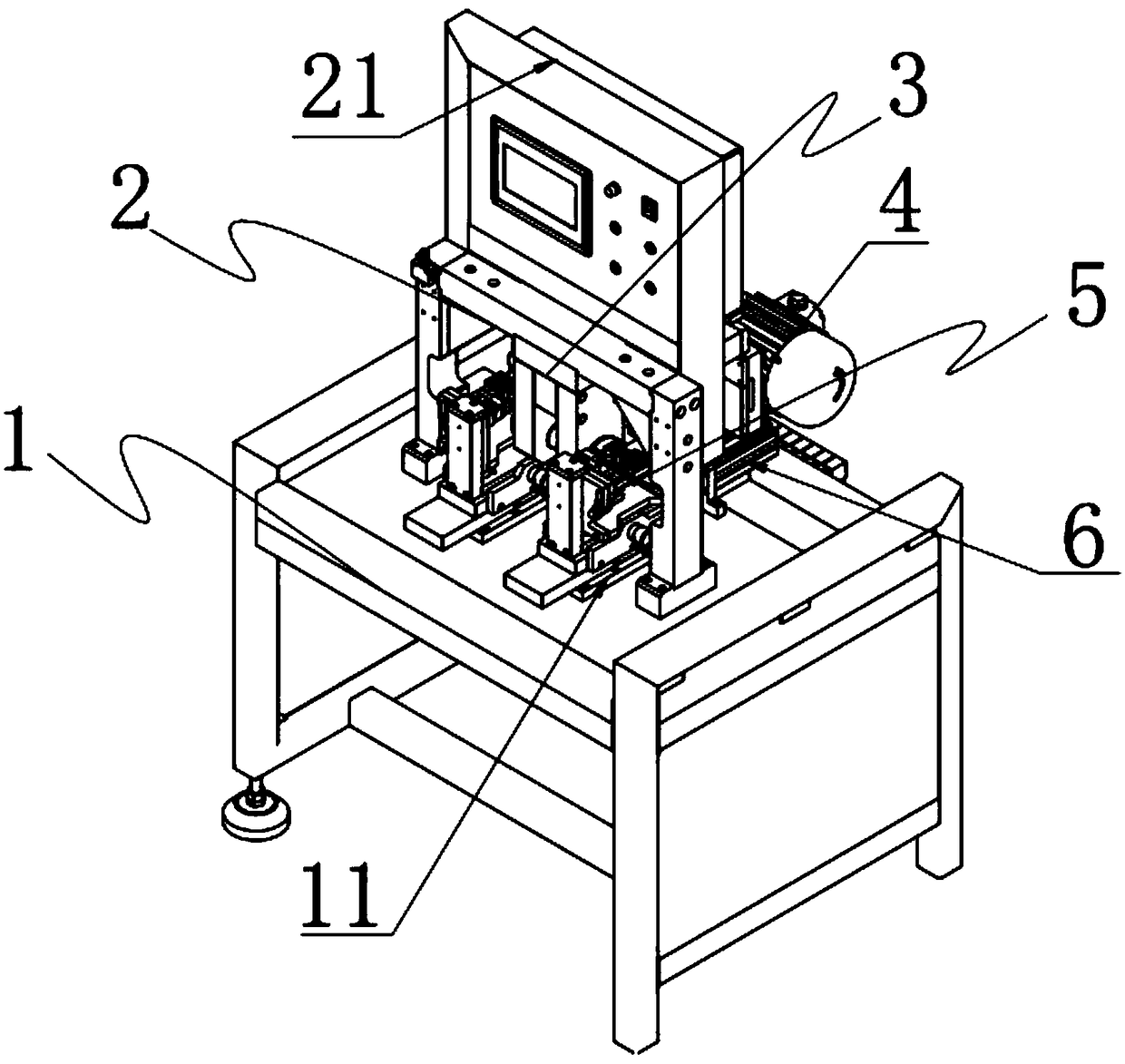

[0027] For a kind of semi-automatic processing glasses glue frame machine provided by Embodiment 1 of the present invention, please refer to figure 1 As shown, it includes a frame 1, the top of the frame 1 is provided with a support 2 and a motor 4 that provides power, and the bottom of the support 2 is connected with a milling cutter assembly 3; the frame 2 is located on the milling cutter assembly 3 Both sides are respectively provided with base plate 11; Described base plate is provided with linear guide rail; Described linear guide rail is provided with the locating fixture 5 that is connected with its sliding fit, and locating fixture can accomplish forward and backward movement along linear guide rail; Each described locating fixture 5 are all corresponding to the milling cutter assembly 3, so that the positioning fixtures on both sides can work at the same time and improve work efficiency; the positioning fixture 5 is provided with an inductor electrically connected to i...

Embodiment 2

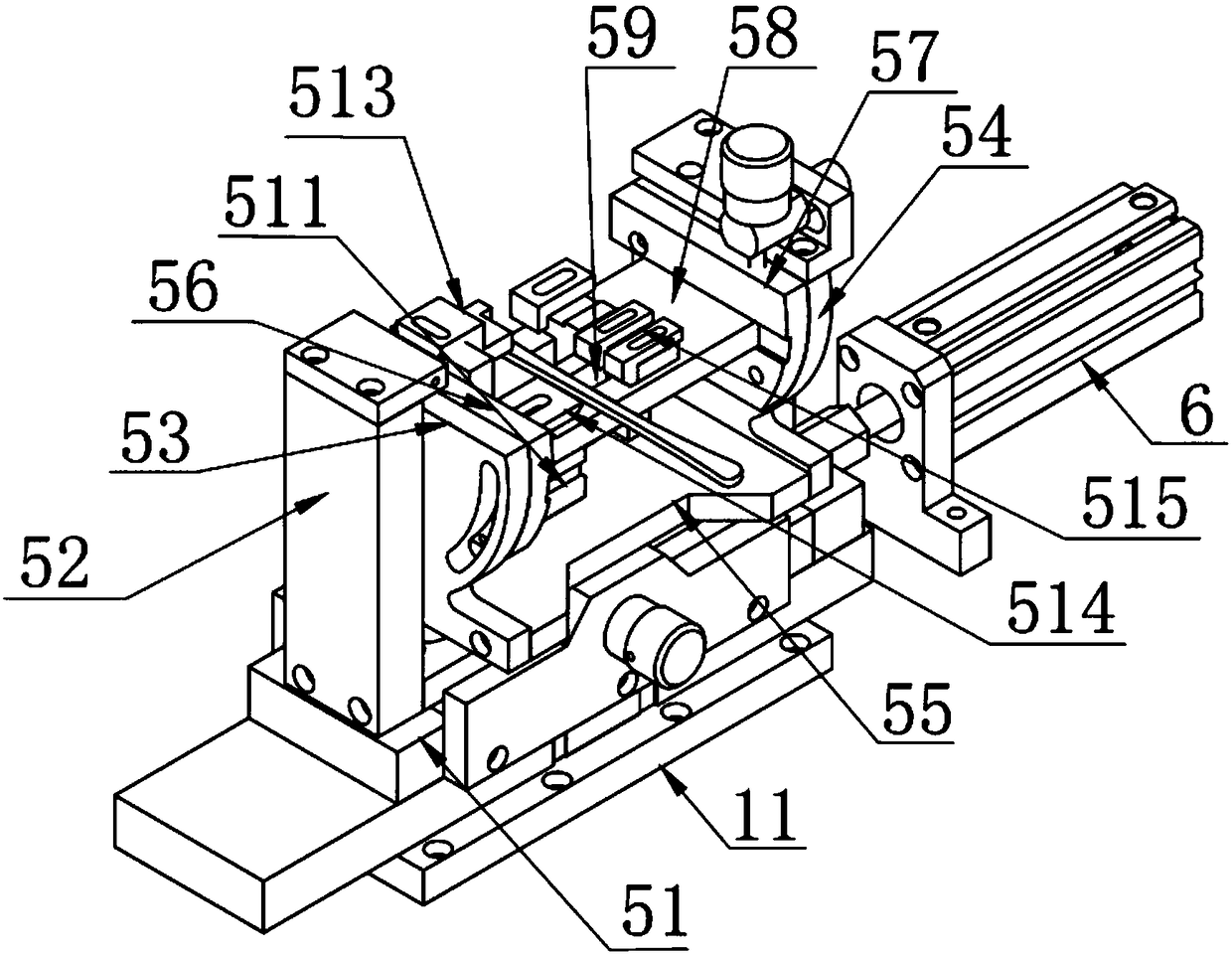

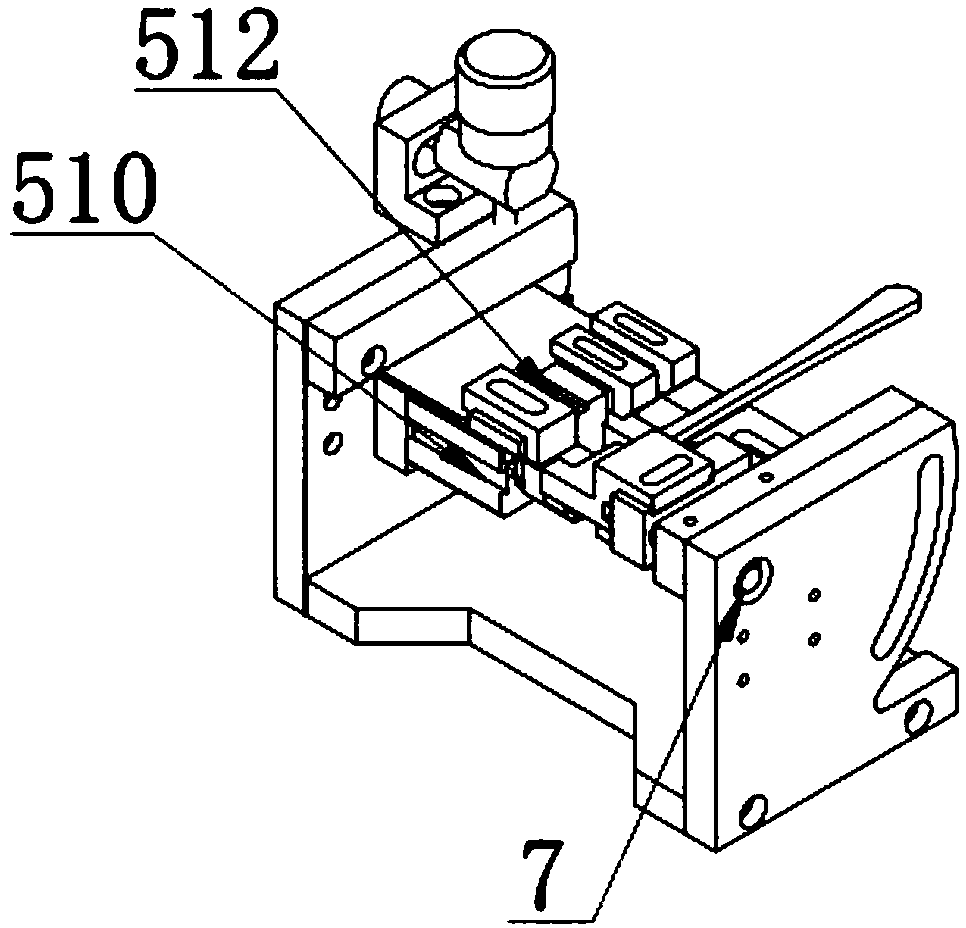

[0030] A kind of semi-automatic processing glasses frame machine provided by Embodiment 2 of the present invention is basically the same as Embodiment 1, the difference is that please refer to figure 2 and image 3 As shown, the positioning fixture 5 includes a base 51 that is slidingly connected to the guide rail, and the top of the base 51 is connected with a micrometer mounting plate 52 near the two ends; the two opposite sides of the micrometer mounting plate 52 are The first rotating shaft supporting plate 53 and the second rotating shaft supporting plate 54 are respectively connected, and the bottom of the first rotating shaft supporting plate 53 and the second rotating shaft supporting plate 54 is connected with an angle adjusting plate 55, and the angle adjusting Both ends of the plate 55 are vertically connected to the first rotating shaft supporting plate 53 and the second rotating shaft supporting plate 54 respectively; A first product placement support plate 56 a...

Embodiment 3

[0033] A kind of semi-automatic processing glasses frame machine provided by Embodiment 3 of the present invention is basically the same as Embodiment 2, the difference is that please continue to refer to figure 2 and image 3 As shown, the two micrometer mounting plates 52 are rotationally connected with the first rotating shaft supporting plate 53 and the second rotating shaft supporting plate 54; the first rotating shaft supporting plate 53 and the second rotating shaft supporting plate 53 Bearings 7 are arranged on the shaft support plates 54, and a rotating shaft is sleeved in the bearings, and the other end of the rotating shaft is connected to the micrometer mounting plate 52 in rotation; it plays a role of rotation and achieves the effect of angle adjustment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap