Large-scale biomass and waste pyrolysis furnace

A biomass and pyrolysis furnace technology, used in coke ovens, indirect heating dry distillation, special forms of dry distillation, etc., can solve the problems that the pyrolyzer cannot be self-heating, hinder heat transfer, etc., and achieves expanded adaptability, less heat, The effect of a large heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

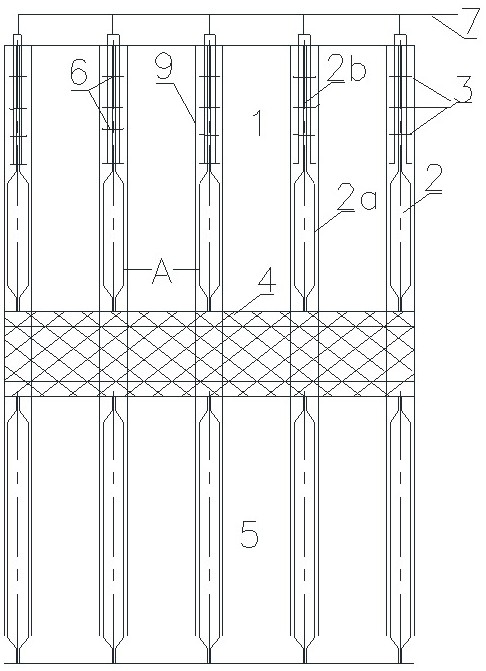

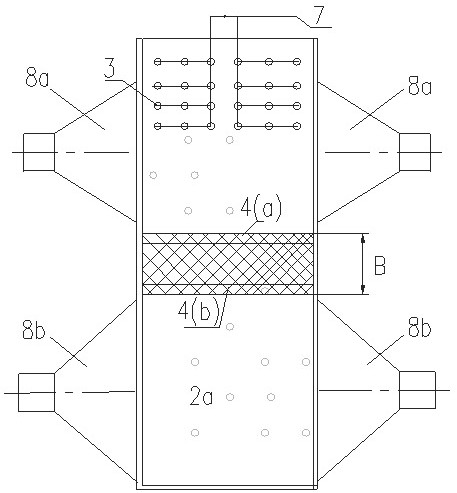

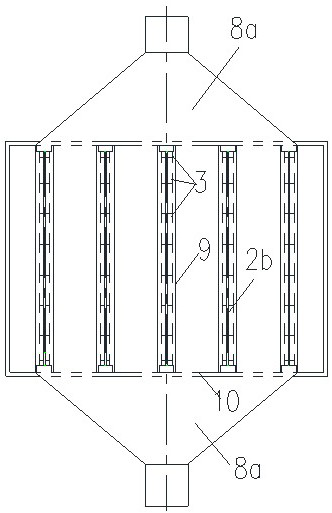

[0060] figure 1 Shows an implementation of a large biomass and waste pyrolysis furnace cavity provided by the present invention, figure 2 The relationship between the layout of the air flow and the position of the heating surface is shown. image 3 with Figure 4 The top view is used to further explain the relationship between the arrangement of the air flow in the preheating zone and the pyrolysis zone and the position of the heating surface. The large-scale pyrolysis furnace of this specific embodiment includes a preheating section nozzle area 1; a heating chamber 2 and heating surfaces 2a on both sides thereof; a nozzle group 3 and a pipe 7 for feeding hot air; the interface between the preheating area and the pyrolysis area 4 is composed of biomass and waste materials; the upper part is the preheating zone temperature control interface 4a; the lower part is the pyrolysis zone temperature control interface 4b; the pyrolysis zone 5; the nozzle holder 6 in the preheating zone...

Embodiment 2

[0065] For a certain batch of sludge treatment tasks of 105 tons / day, after drying, the moisture content is still as high as 45%. The large-scale pyrolysis furnace adopts the pyrolysis ( figure 1 ), the sludge is fed to the preheating section 1 by the cooperation of the uniform blanking mechanism and the heating surface cleaning mechanism 9 configured in the system; the generated water vapor is guided and discharged by the water vapor outlet area 8a, according to formulas (1) and (2) ) Controlling the hot flue gas flow rate of 350°C from the nozzle 3 and the pumping volume of the water vapor outlet area 8a, so that the temperature at the temperature control interface 4a of the preheating zone is controlled at about 95°C. There is a distance A between the heating surface at the lower edge of the water vapor outlet area 8a away from 4a. The preheated and dried material descends to the pyrolysis zone 5. The heating chamber inside the heating surface 2a of the pyrolysis zone is fe...

Embodiment 3

[0067] A certain batch of reed straw harvested in summer has a moisture content of up to 52%, a processing capacity of 100 tons / day, and a maximum particle size of 30 mm after crushing. The large pyrolysis furnace of the present invention is used for pyrolysis ( figure 1 ), the broken reed straw is fed to the preheating section 1 by the cooperation of the uniform blanking mechanism (such as the uniform blanking mechanism disclosed in Chinese invention patent 201410412201.2) and the heating surface cleaning mechanism 9 configured in the system; the nozzle 3 sprays 380 The hot flue gas at ℃ directly heats the straw, and the generated water vapor is guided and discharged by the water vapor outlet area 8a. According to formulas (1) and (2), the flow rate of the hot flue gas ejected from the nozzle 3 and the exhaust volume of the outlet area 8a are controlled. The temperature at the temperature control interface 4a of the preheating zone is controlled at about 95°C. The distance bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com