A production process of aluminum alloy medium-thick plate applied to tablet computer backplane

A tablet computer and production process technology, applied in the field of aluminum alloy plate processing, can solve the problems of high economic cost, inability to guarantee plate uniformity and performance consistency, and low production efficiency, so as to improve production efficiency and ensure uniformity and performance Consistency, good punchable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

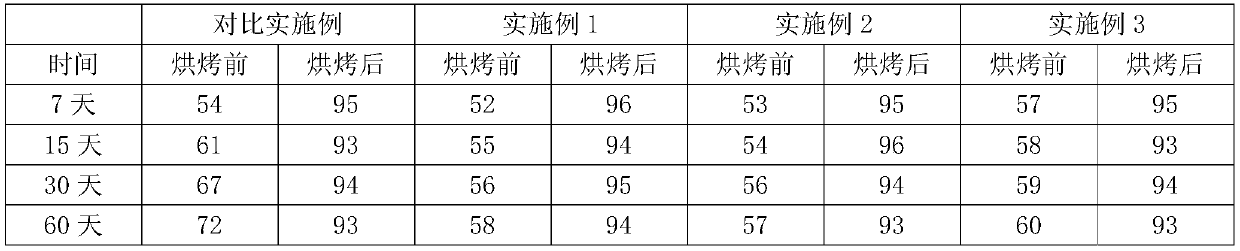

Examples

Embodiment 1

[0023] A production process of aluminum alloy medium and thick plates applied to the back plate of tablet computers is to put the aluminum alloy plate into a solid solution heat treatment furnace, heat it at 530°C for 8 minutes, and then carry out water cooling, and then put the aluminum alloy plate after water cooling in Put it into an air resistance furnace with a temperature of 200°C for pre-aging treatment within 3 hours. When the temperature of the aluminum alloy sheet reaches 120°C, take out the aluminum alloy sheet, and use a fan to cool the aluminum alloy sheet within 1 hour until the temperature is lower than 60°C. ℃, tested after cooling, and the finished product is obtained;

[0024] Wherein, the model of the aluminum alloy plate is 6463 aluminum alloy plate; the chemical composition of the 6463 aluminum alloy plate includes the following components in weight percentage: Si=0.3%, Fe≤0.10%, Cu≤0.05%, Mn≤ 0.05%, Mg=0.45%, Cr≤0.05%, Zn≤0.05%, Ti≤0.05%; other individual...

Embodiment 2

[0030] A production process of aluminum alloy medium and thick plates applied to the backboard of tablet computers is to put the aluminum alloy plate into a solid solution heat treatment furnace, heat it at 540°C for 15 minutes, and then carry out water cooling, and put the water-cooled aluminum alloy plate in Put it into an air resistance furnace with a temperature of 300°C for pre-aging treatment within 3 hours. When the temperature of the aluminum alloy sheet reaches 140°C, take out the aluminum alloy sheet and use a fan to cool the aluminum alloy sheet within 1 hour until the temperature is lower than 60°C. ℃, tested after cooling, and the finished product is obtained;

[0031] Wherein, the model of the aluminum alloy plate is 6463 aluminum alloy plate; the chemical composition of the 6463 aluminum alloy plate includes the following components in weight percentage: Si=0.4%, Fe≤0.10%, Cu≤0.05%, Mn≤ 0.05%, Mg=0.55%, Cr≤0.05%, Zn≤0.05%, Ti≤0.05%; other individual elements≤0.0...

Embodiment 3

[0037] A production process of aluminum alloy medium and thick plates applied to the back plate of tablet computers is to put the aluminum alloy plate into a solid solution heat treatment furnace, heat it at 535°C for 10 minutes, and then carry out water cooling, and put the water-cooled aluminum alloy plate in Put it into an air resistance furnace with a temperature of 280°C for pre-aging treatment within 2 hours. When the temperature of the aluminum alloy sheet reaches 130°C, take out the aluminum alloy sheet and use a fan to cool the aluminum alloy sheet within 1 hour until the temperature is lower than 60°C. ℃, tested after cooling, and the finished product is obtained;

[0038]Wherein, the model of the aluminum alloy plate is 6463 aluminum alloy plate; the chemical composition of the 6463 aluminum alloy plate includes the following components in weight percentage: Si=0.35%, Fe≤0.10%, Cu≤0.05%, Mn≤ 0.05%, Mg=0.50%, Cr≤0.05%, Zn≤0.05%, Ti≤0.05%; other individual elements≤0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com