Substrate table system and method for improving growth uniformity of diamond film by using same

A diamond film and substrate table technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problem of unsatisfactory diamond film growth uniformity, difficult substrate temperature distribution, excessive metal impurities and other problems, to achieve the effects of easy timely control, efficient temperature distribution, and simple processing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

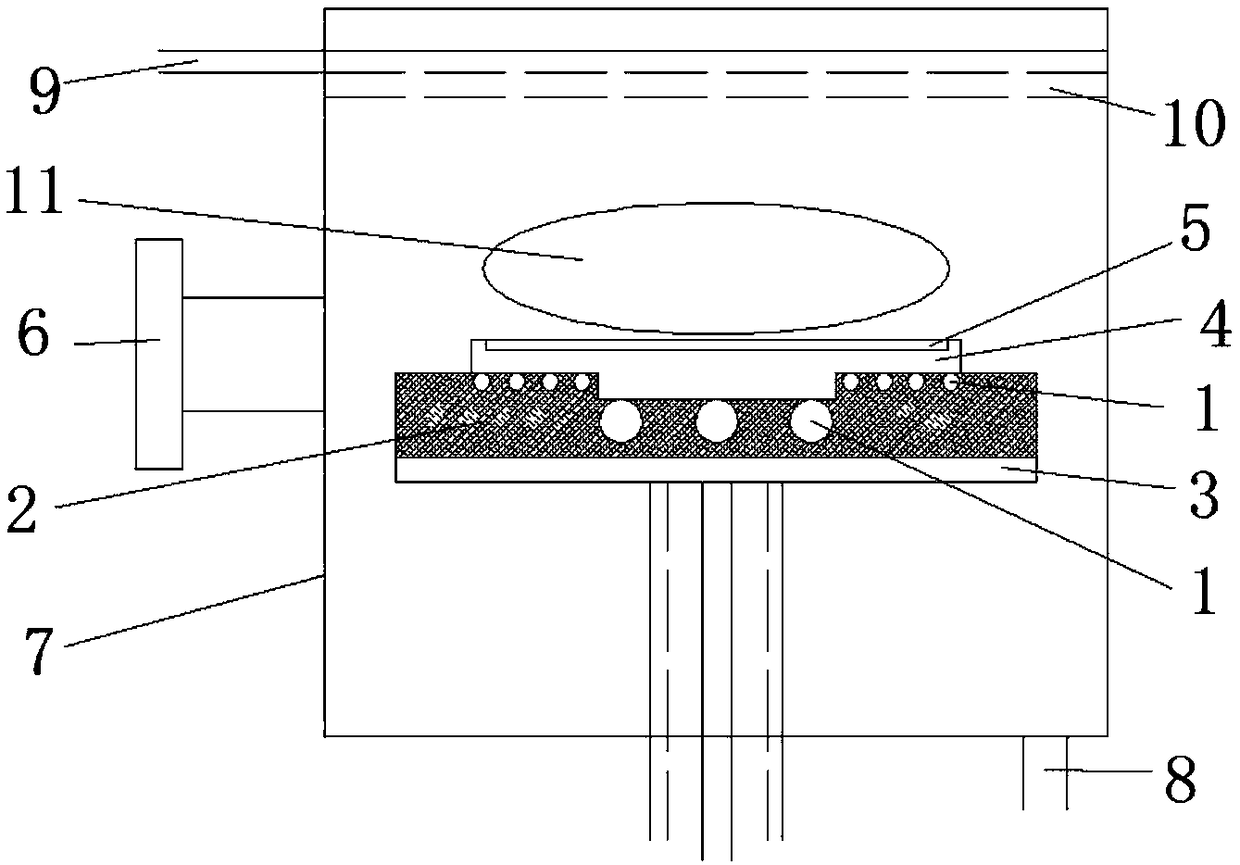

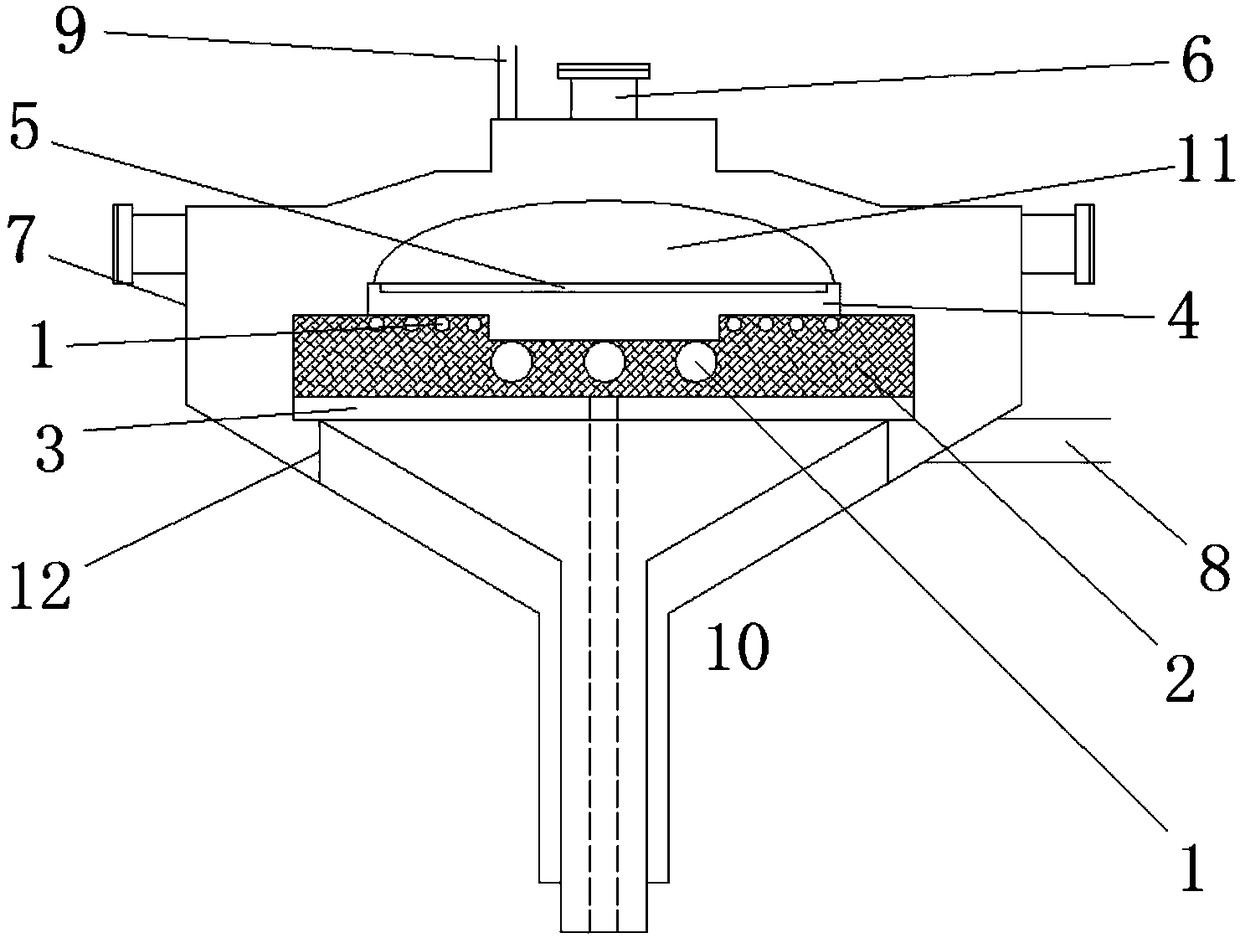

[0040] A method for improving the uniformity of diamond film growth, specifically comprising the steps of:

[0041] S100. Processing and assembly of the substrate stage system:

[0042] Choose cold water pipes 1 with a diameter of 8 mm, and arrange them in the central area where the substrate table support 3 connects to the substrate table 4 with a water pipe spacing of 2.5 mm. Choose cold water pipes 1 with a diameter of 5 mm and arrange them with a water pipe spacing of 4 mm. In other areas where the substrate stage support 3 is connected to the substrate stage 4, the proportion of the area where the 8mm water cooling tube 1 is arranged is 1 / 4 to 1 / 2 of the total area (the area of the substrate stage 4), and the 5mm water cooling tube 1 The proportion of the arranged area is 1 / 2 to 3 / 4 of the total area (the area of the substrate stage 4), and the gap between the water cooling tube 1 and the substrate stage support 3 is filled with brazing filler 2, wherein the brazing ...

Embodiment 2

[0048] A method for improving the uniformity of diamond film growth, specifically comprising the steps of:

[0049] S100. Processing and assembly of the substrate stage system:

[0050] Choose cold water pipes 1 with a diameter of 10mm, and arrange them in the central area where the substrate table support 3 and substrate table 4 are connected with a water pipe spacing of 1.5mm, and choose cold water pipes 1 with a diameter of 6mm, and arrange them with a water pipe spacing of 3mm In other areas where the substrate stage bracket 3 is connected to the substrate stage 4, the proportion of the area where the 10mm water cooling tube 1 is arranged is 1 / 4 to 1 / 2 of the total area (the area of the substrate stage 4), and the 6mm water cooling tube 1 The proportion of the arranged area is 1 / 2 to 3 / 4 of the total area (the area of the substrate stage 4), and the gap between the water cooling tube 1 and the substrate stage support 3 is filled with brazing filler 2, wherein the brazi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com