Construction method of uplift pressure resisting concrete protection slab

A construction method and technology for protective panels, applied in the direction of coastline protection, can solve problems such as cracks, fractures, and instability of concrete protective panels, and achieve the effect of extending the service life, increasing the construction progress, and weakening the effects of scouring and soaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

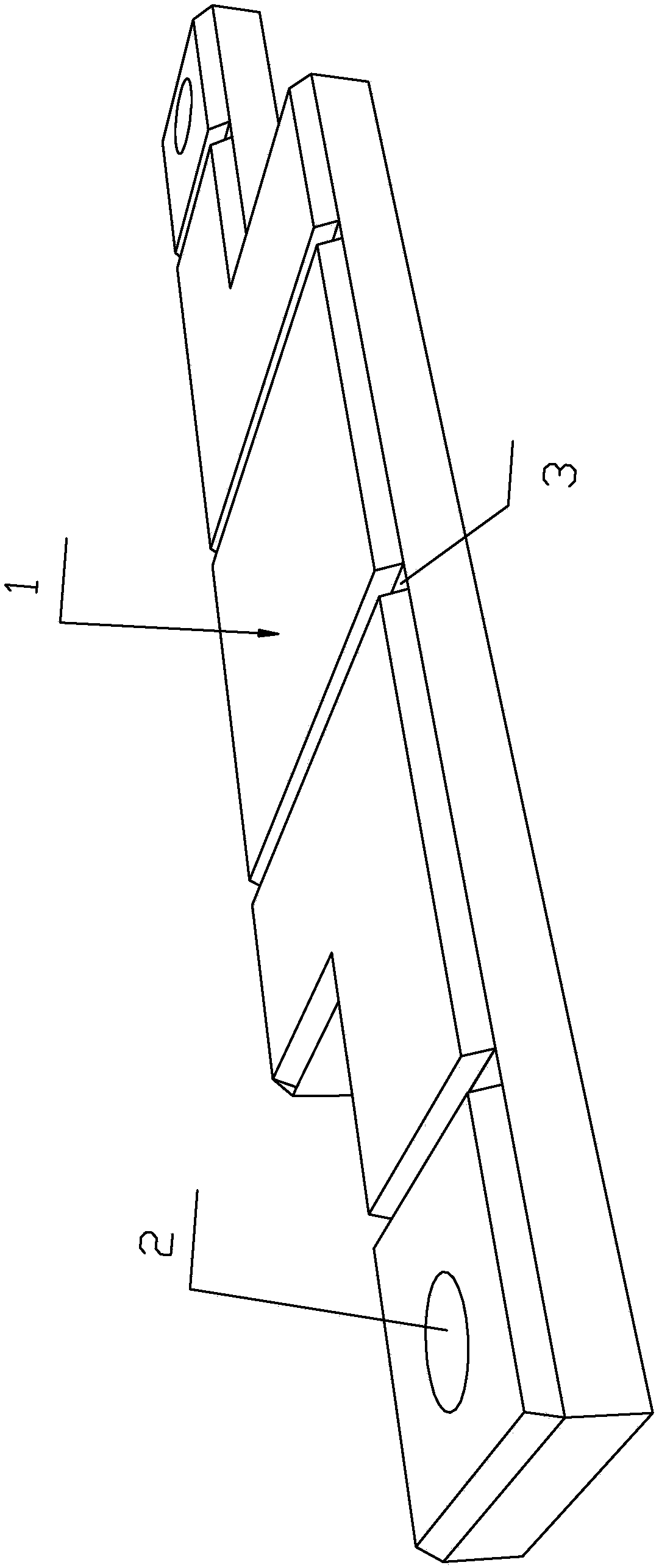

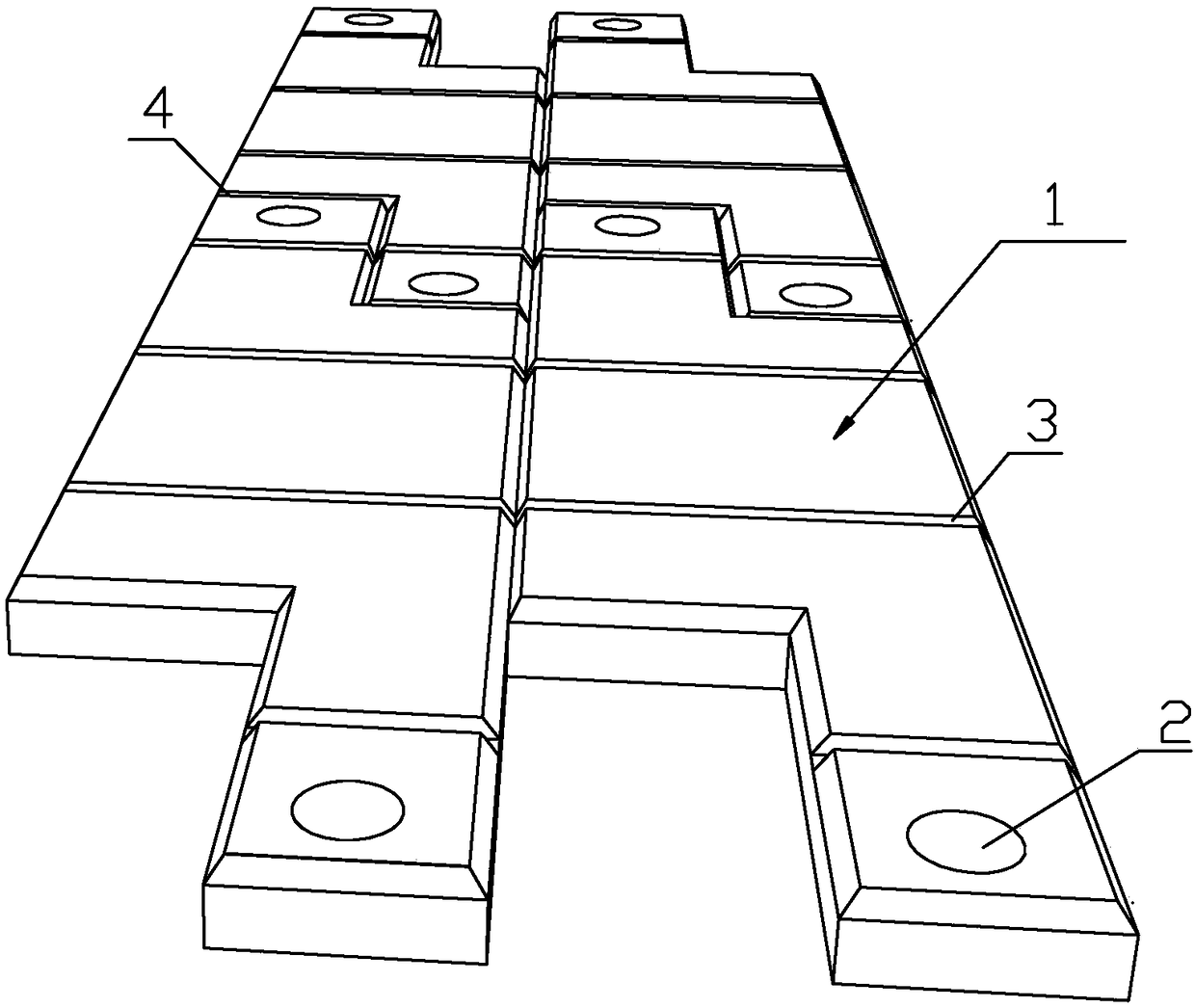

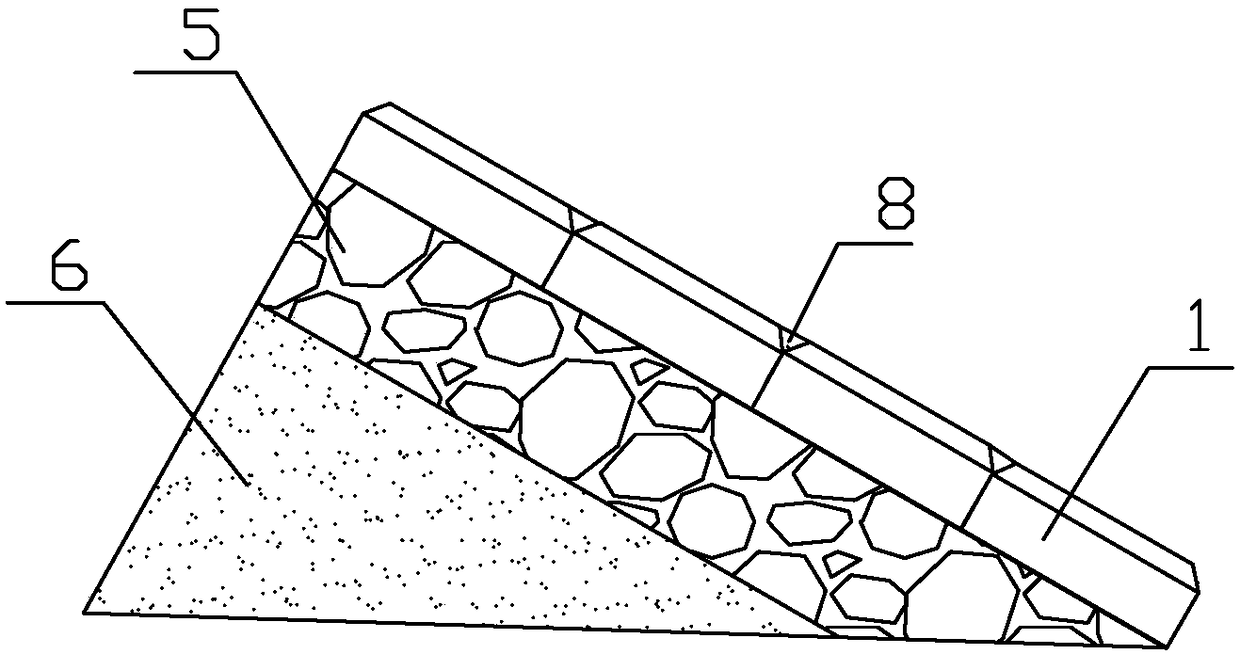

[0030] Such as Figure 1 to Figure 4 Shown, be the construction method of a kind of anti-floating force of the present invention concrete guard plate, comprise the steps:

[0031] a. Construction measurement and stakeout

[0032] Before construction, it is necessary to carry out lofting, and release the longitudinal joint position line of the concrete panel 1 on the plane of the cushion;

[0033] b. Base cleaning

[0034] Excavation shall be carried out according to the longitudinal joint position line determined by stakeout and the designed cushion thickness. During the excavation, the excavation shall be carried out in accordance with the principle of layered excavation from top to bottom, and inspection shall be carried out while excavating. , transport the excavated earth away;

[0035] c. Tamp the foundation and replace the cushion

[0036] Transport away the excavated earth from the foundation, instead of backfilling with the original soil, first compact the soil lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com