Aqueduct for water conservancy project

A technology for water conservancy projects and aqueducts, applied in water conservancy projects, artificial waterways, buildings, etc., can solve problems such as reduced service life, leakage at expansion joints, and easy corrosion, so as to improve service life, reduce impact force, and reduce impact force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

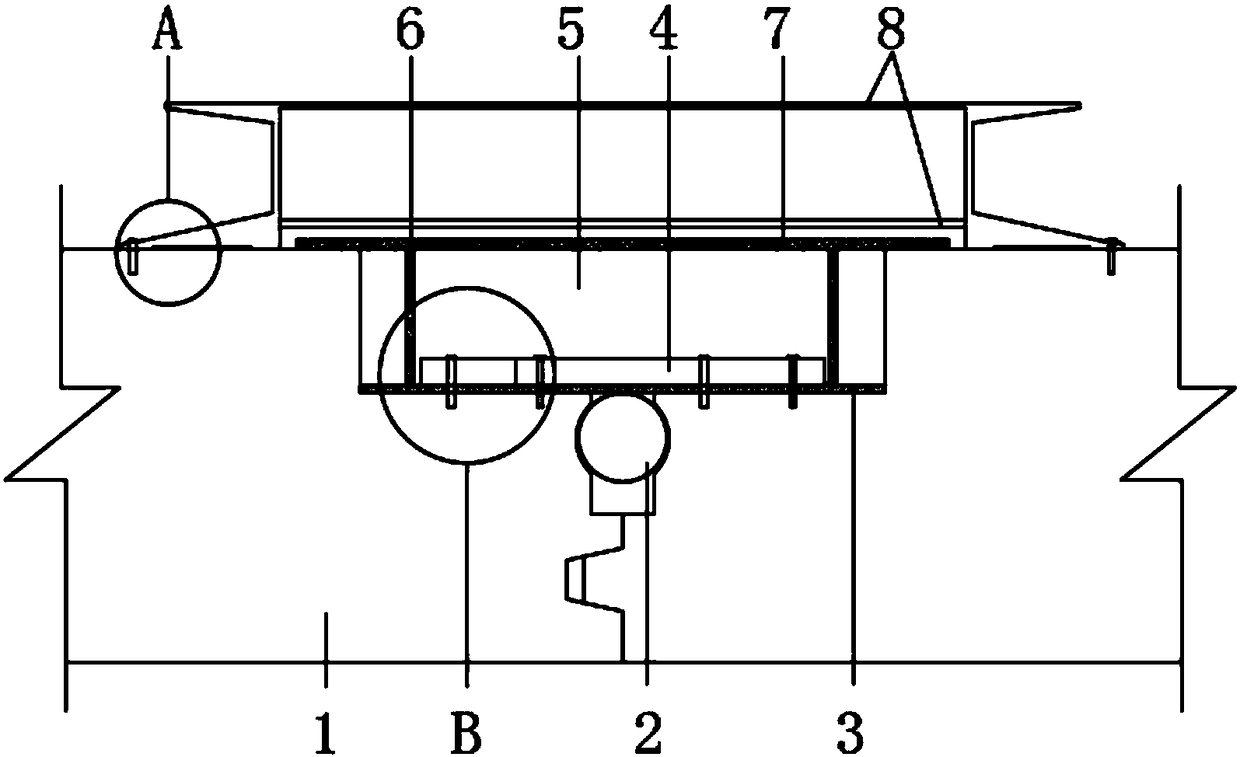

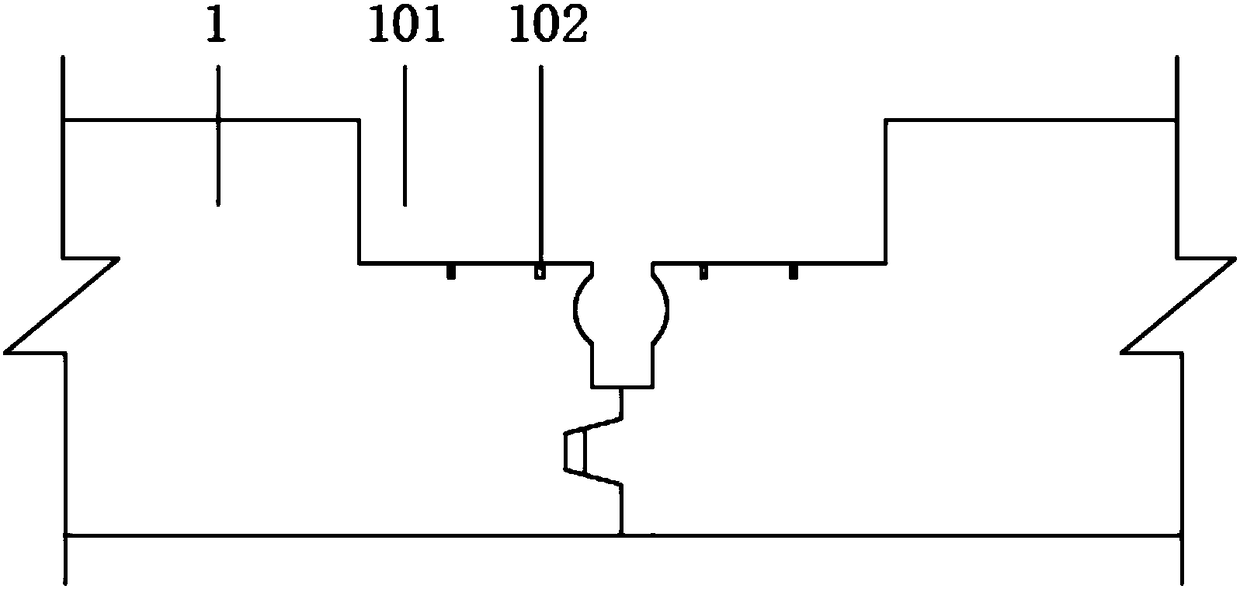

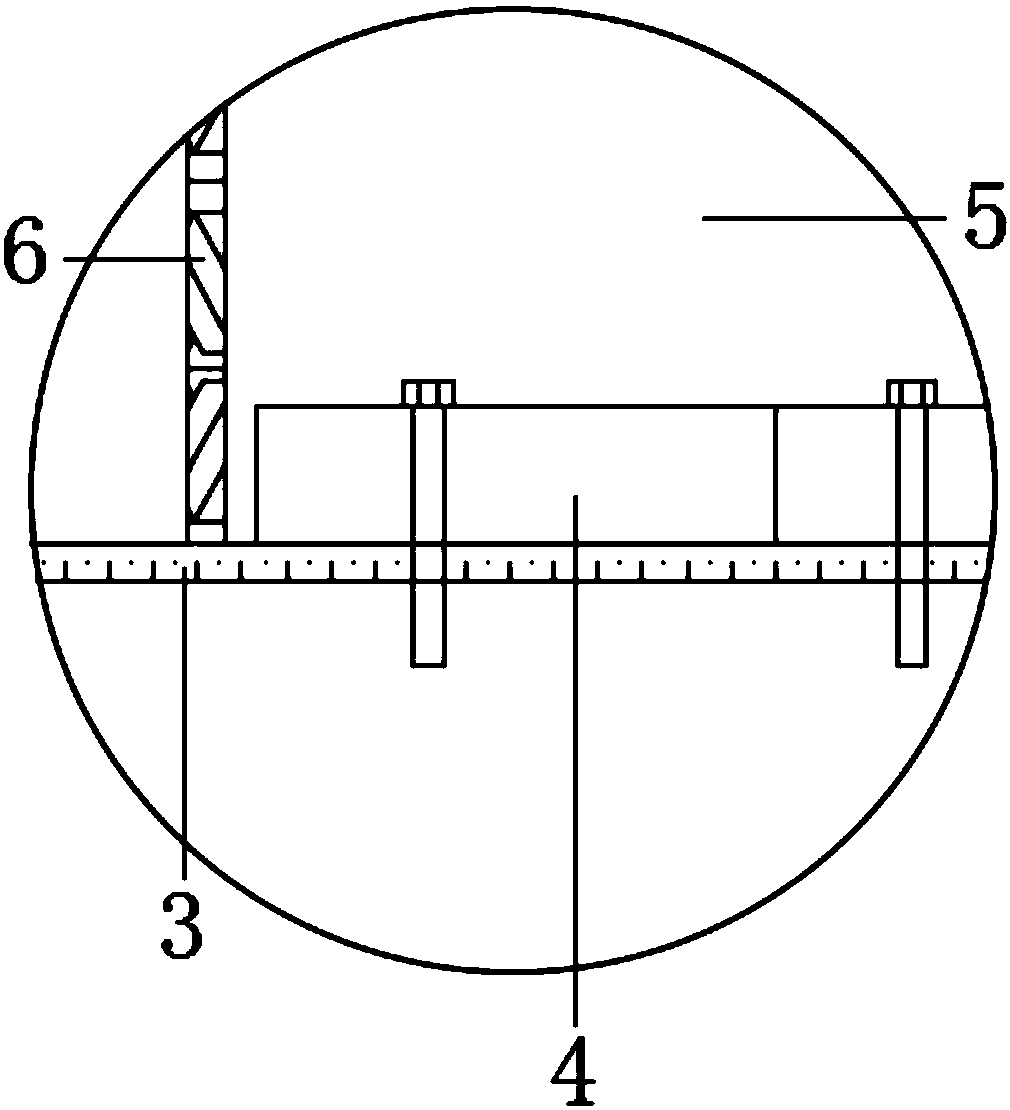

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034] The present invention provides an aqueduct for water conservancy projects, comprising an aqueduct body 1, a slot 101, a reserved hole 102 for expansion bolts, a glue stick 2, an EPDM composite GB waterstop 3, a stainless steel pressure plate 4, and a first pressure plate 401, the second pressing plate 402, rubber cushion 403, polymer mortar 5, GB flexible water stop plate 6, PCS flexible waterproof coating 7, protective cover 8, partition 801, sealing gasket 802 and filter screen 803; the aqueduct The front end of the body 1 is provided with a slot 101, and the bottom of the slot 101 is provided with a reserved hole 102, the glue stick 2 is inserted into the expansion joint between the two aqueduct bodies 1, and the aqueduct body 1 is slotted 101 The bottom of the EPDM composite GB waterstop 3 is pasted with an adhesive, and the EPDM composite GB waterstop 3 is fixed on the expansion joint through a 4mm thick st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com