Foundation pit supporting structure and construction method thereof

A foundation pit support and support structure technology, which is applied in foundation structure engineering, excavation, construction, etc., can solve the problem of low material utilization rate, achieve high material utilization rate, strong anti-overturning ability of support, and fast construction speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

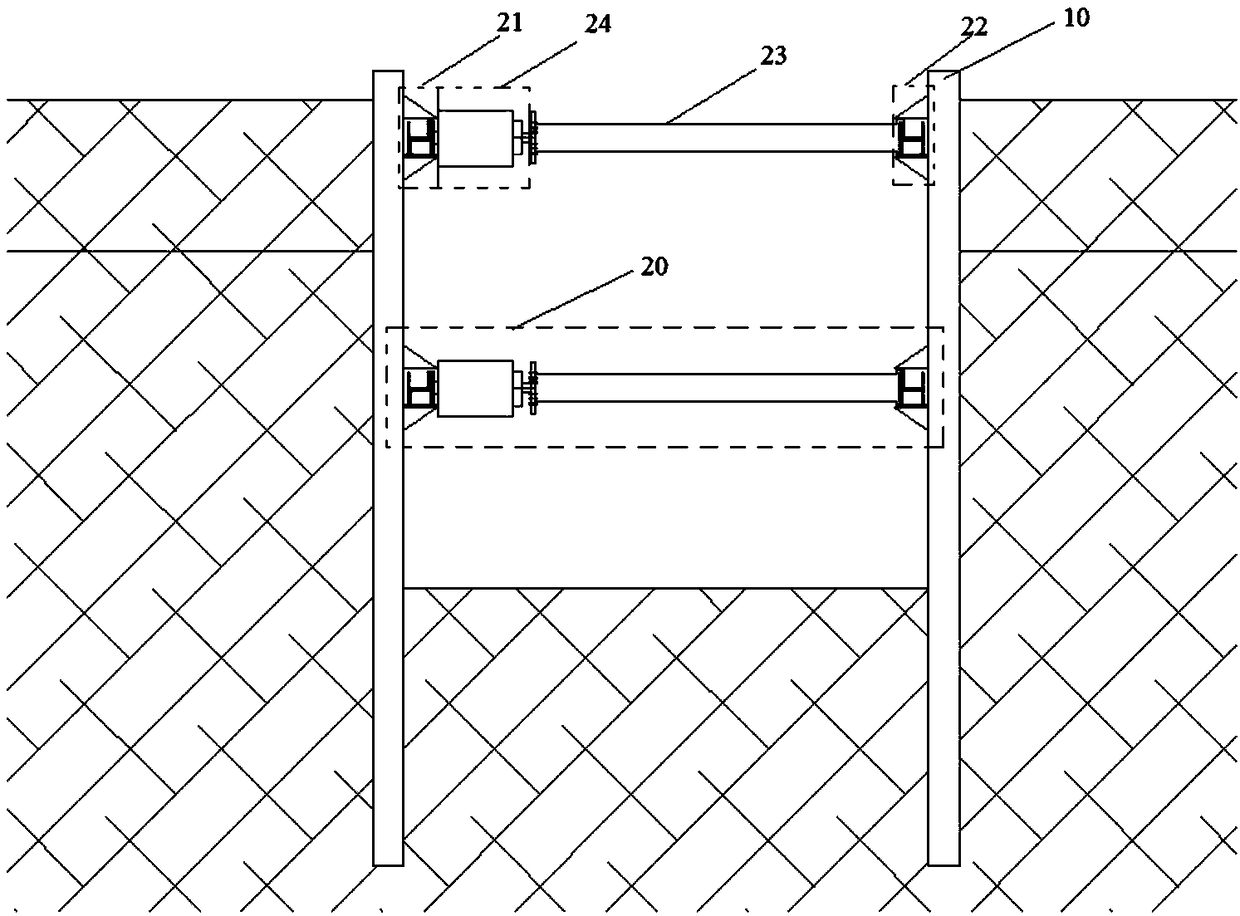

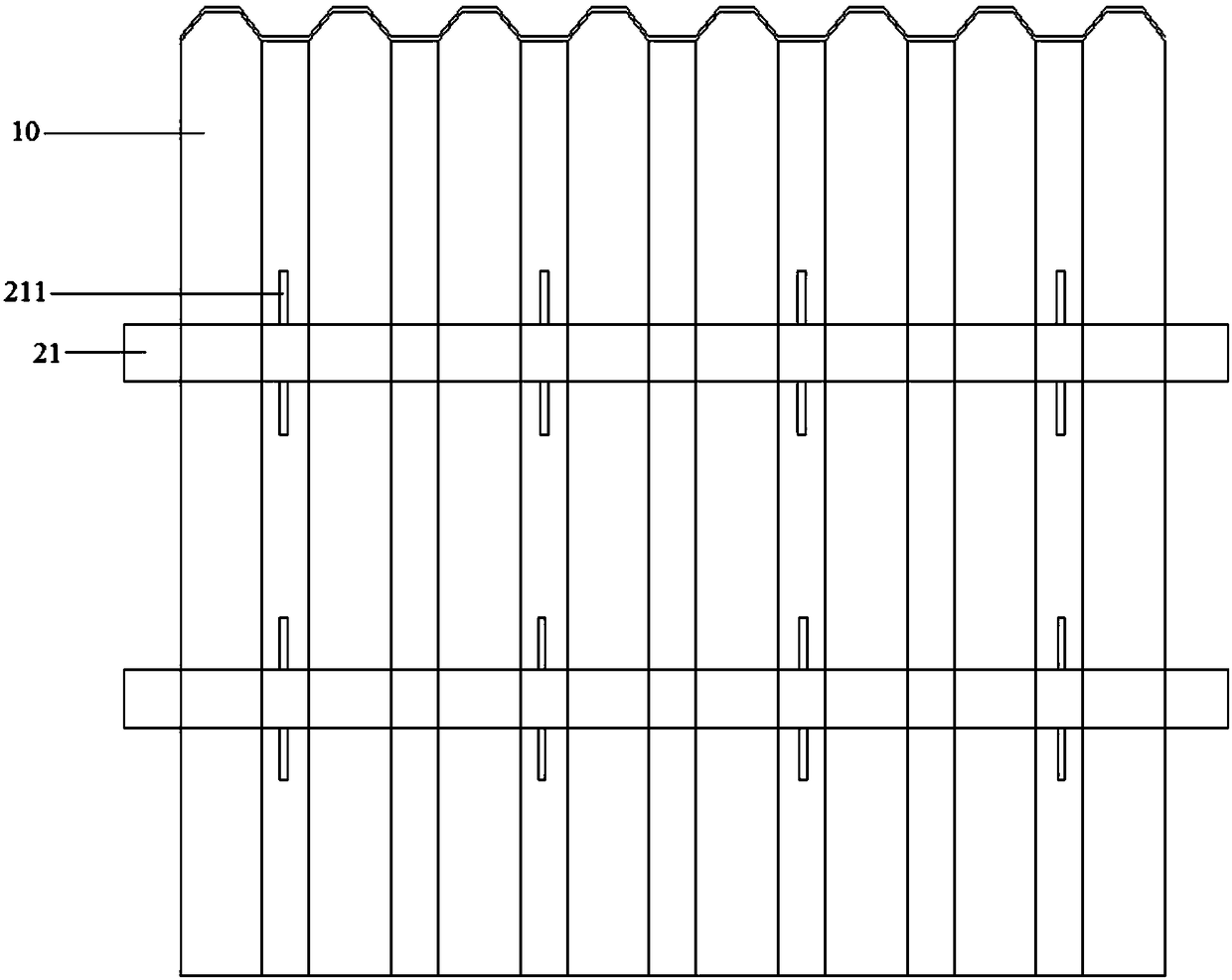

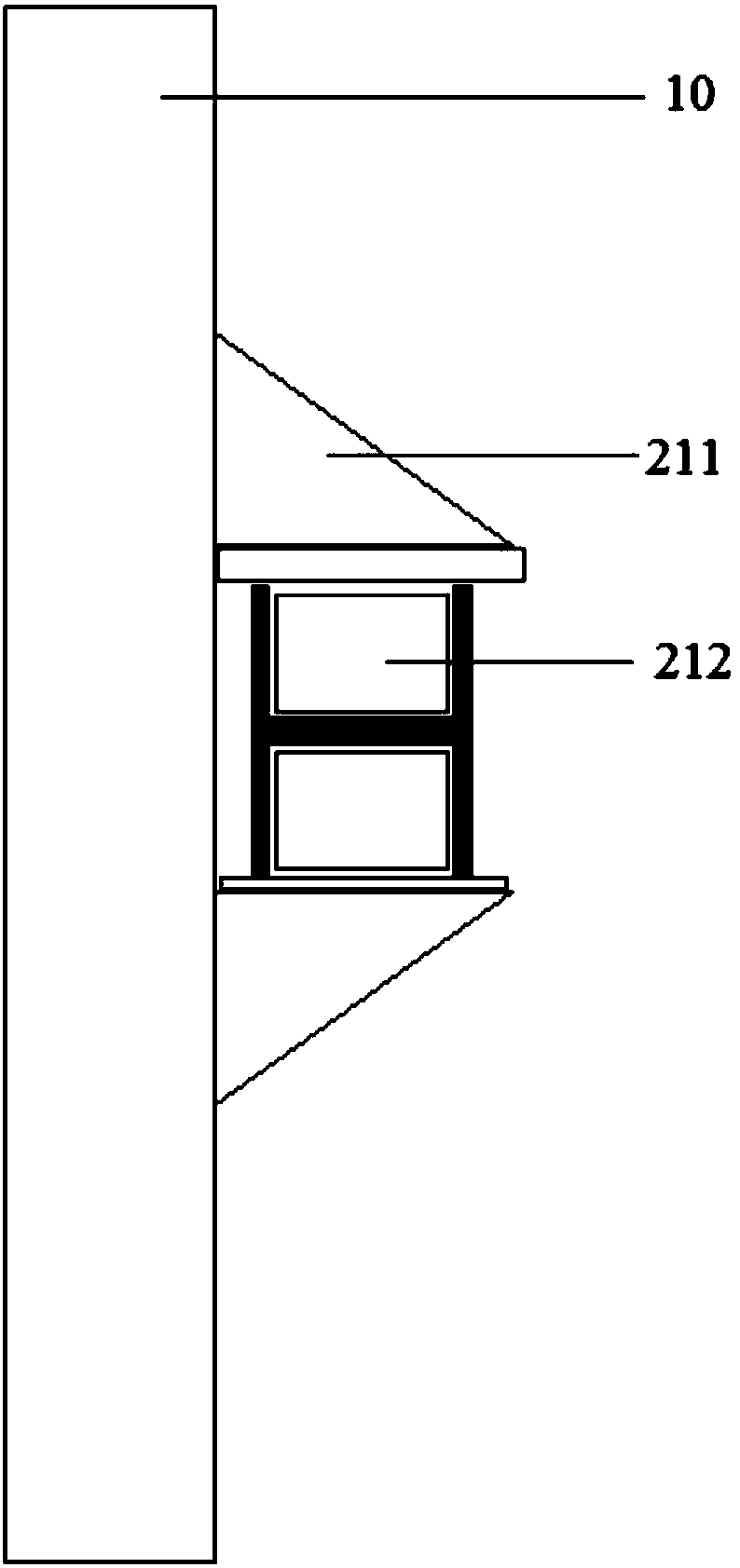

[0078] As a specific implementation of this embodiment, it specifically includes:

[0079] 1) According to the soil layer parameters provided by the geological exploration report, combined with the depth of the foundation pit, and considering the influence of various factors such as precipitation, determine the length of the steel sheet pile 10, the supporting waist beam, the internal supporting structure 23 and the length control device 24 with a force-increasing function. parameter. In the embodiment, transmission gear set 242 power gear 24210 teeth number Z 1 =20, modulus m 1 =2.5, steering gear 24211 tooth number Z 2 =60, modulus m 2 =2.5, transmission ratio i 1 = 3; Axial rotation gear 24213 teeth number Z 1 =2, modulus m 1 =3, power over gear 24214 tooth number Z 2 =100, modulus m 2 = 3, transmission ratio i 2 =50; power transmission gear 24215, plane transition gear 24218, and hydraulic rod homing power gear 24219 have 32 teeth Z, and modulus m is 7; hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com