A low-nitrogen high-efficiency burn-out w-flame boiler dominated by side walls with symmetrical combustion

A symmetrical and flame technology, which is applied in the field of W flame boiler combustion, low nitrogen and high efficiency burnout W flame boiler, and can solve the problems of increasing the cost of the boiler body and NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

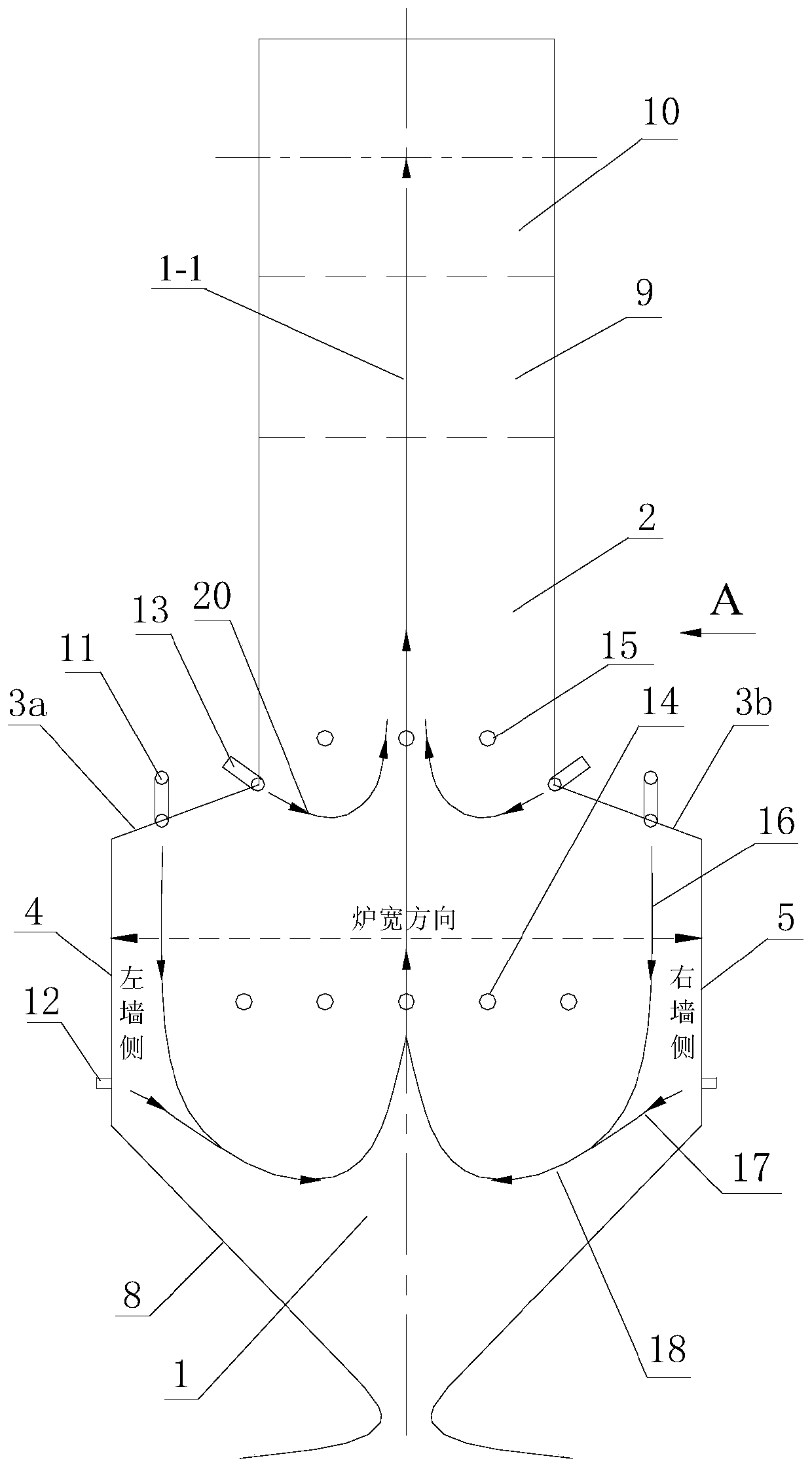

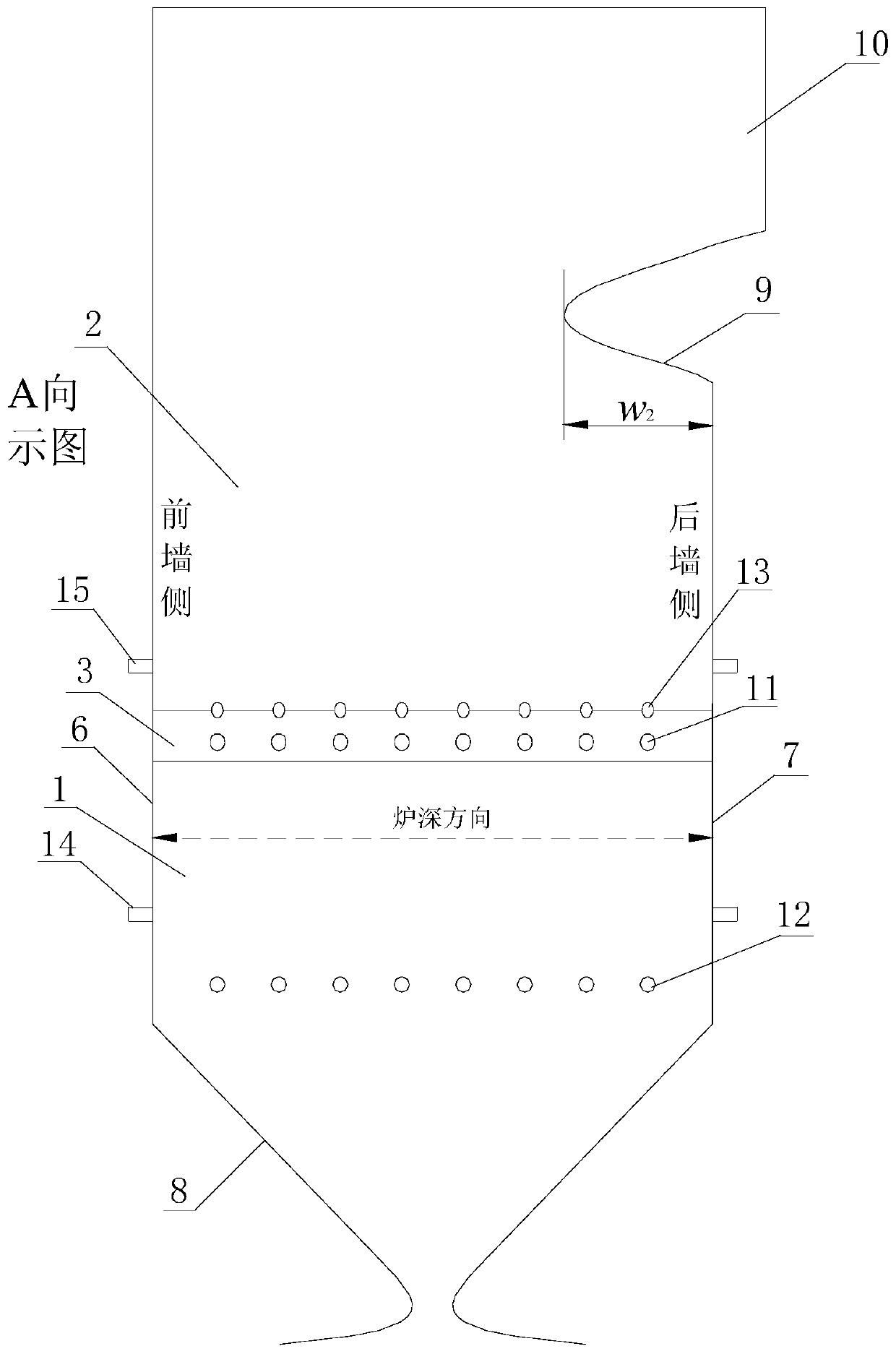

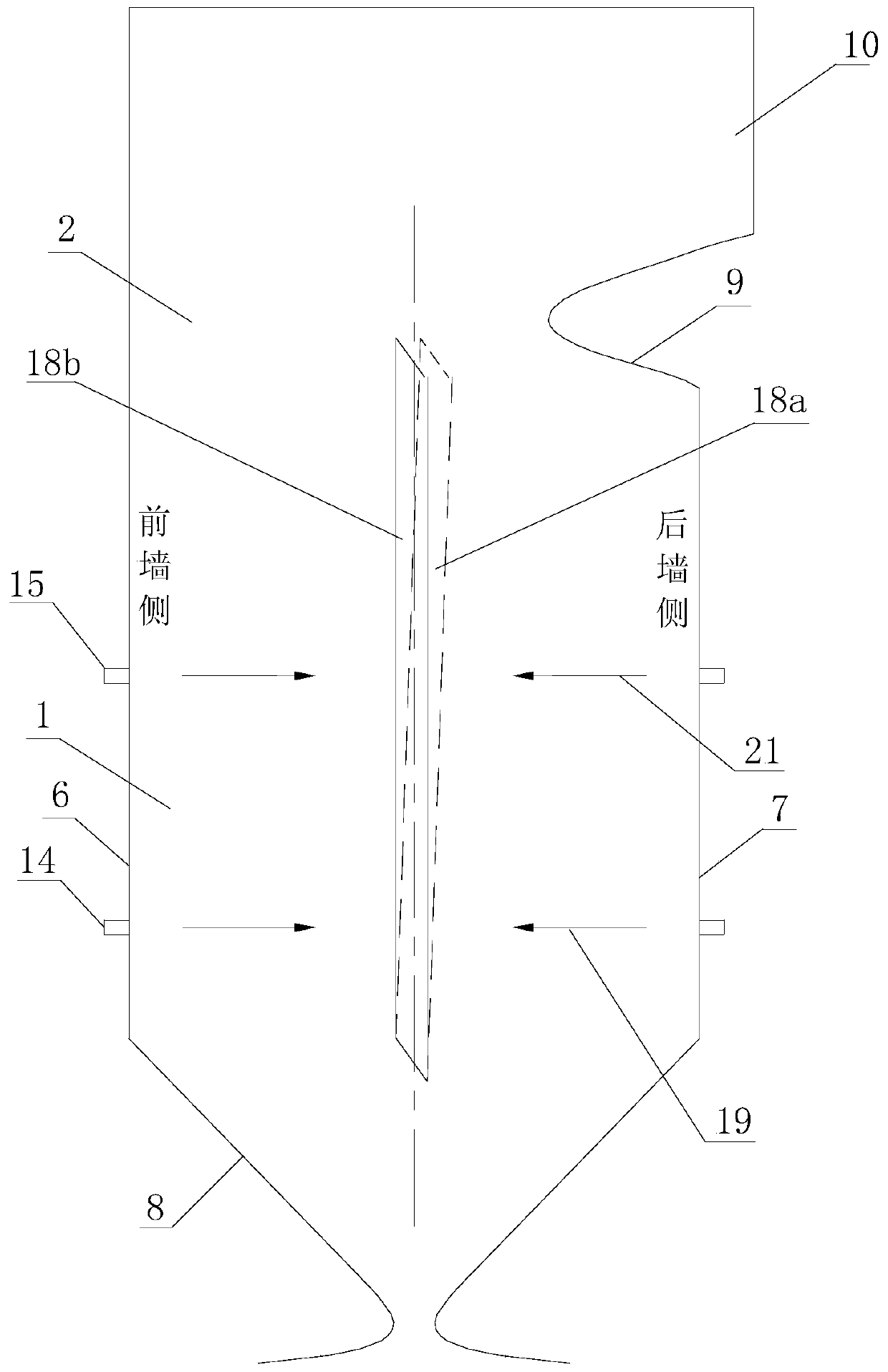

[0027] to combine Figure 1 ~ Figure 3 To illustrate this embodiment, the furnace of a low-nitrogen high-efficiency burn-out W flame boiler dominated by side walls and symmetrical combustion described in this embodiment is divided into a lower furnace 1 and an upper furnace 2, and the lower furnace 1 is composed of a furnace arch 3, a left furnace Wall 4, right wall 5, front wall 6, back wall 7 and cold ash hopper 8, the upper furnace 2 is composed of left wall 4, right wall 5, front wall 6, rear wall 7, flame angle 9 and furnace outlet 10, the flame angle 9 and the furnace outlet 10 are arranged on the rear wall 7 side of the upper furnace 2; the two furnace arches 3 located at the intersection of the upper furnace 1 and the lower furnace 2 are symmetrically arranged on the left wall 4 and the left furnace arch 3a and right furnace arch 3b on the side of the right wall 5; a plurality of arch burner nozzles 11 arranged in a "one" shape along the furnace depth direction and com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com