High-temperature-resistant high-wear-resistant nickel-based titanium carbide powder and preparation method thereof

A highly wear-resistant and high-temperature resistant technology, applied in coatings, metal material coating processes, melt spraying, etc., can solve the problem of decreased coating toughness, increased carbon content of the binder phase nickel-based alloys, and difficult coating performance. To meet the requirements of use and other issues, to achieve the effect of improving hardness and improving high temperature wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

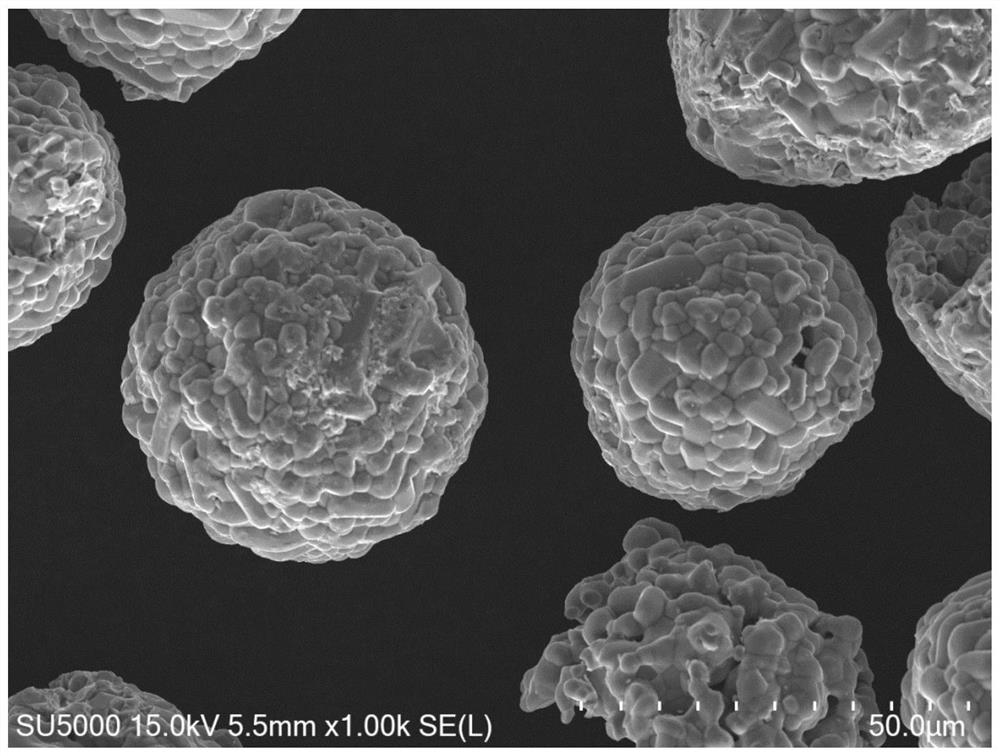

Image

Examples

Embodiment 1

[0021] 1) Weigh 75kg of TiC powder and 25kg of NiCrAlSiX powder, wherein Cr accounts for 20% of NiCrAlSiX, Al accounts for 8% of NiCrAlSiX, Si accounts for 1% of NiCrAlSiX, W+V accounts for 5% in total, and the balance is Ni;

[0022] 2) Mix the above two powders evenly, add deionized water to make a wet grinding medium, add 2.5 kg of polyvinyl alcohol as a binder, a small amount of antioxidant and defoamer, and ball mill for 48 hours to prepare a mixed slurry;

[0023] 3) The agglomerated powder was prepared by centrifugal spray drying, wherein the inlet temperature was 210°C, the outlet temperature was 110°C, the rotation speed of the atomizing disc was 12000 / min, and the feeding volume was 300ml / min;

[0024] 4) Heat the powder in a vacuum degumming furnace, the sintering temperature is 1330°C, keep it warm for 3 hours, and then cool it to below 150°C with the furnace;

[0025] 5) After sieving and grading the above-mentioned powder after being released from the furnace, a ...

Embodiment 2

[0028] 1) Weigh 50kg of TiC powder and 50kg of NiCrAlSiX powder, wherein Cr accounts for 23% of NiCrAlSiX, Al accounts for 10% of NiCrAlSiX, Si accounts for 1.8% of NiCrAlSiX, W+V accounts for 5% in total, and the balance is Ni;

[0029] 2) Mix the above two powders evenly, add deionized water to make a wet grinding medium, add 2.8 kg of polyvinyl alcohol as a binder, a small amount of antioxidant and defoamer, and ball mill for 48 hours to obtain a mixed slurry;

[0030] 3) The agglomerated powder was prepared by centrifugal spray drying, wherein the inlet temperature was 210°C, the outlet temperature was 110°C, the rotation speed of the atomizing disc was 12000 / min, and the feeding volume was 300ml / min;

[0031] 4) Heat the powder in a vacuum degumming furnace, the sintering temperature is 1325°C, keep it warm for 3 hours, and then cool it to below 150°C with the furnace;

[0032] 5) After sieving and grading the above-mentioned discharged powder, a powder suitable for spray...

Embodiment 3

[0035] 1) Weigh 60kg of TiC powder and 40kg of NiCrAlSiX powder, wherein Cr accounts for 23% of NiCrAlSiX, Al accounts for 10% of NiCrAlSiX, Si accounts for 1.8% of NiCrAlSiX, W+V accounts for 5% in total, and the balance is Ni;

[0036] 2) Mix the above two powders evenly, add deionized water to make a wet grinding medium, add 2.8 kg of polyvinyl alcohol as a binder, a small amount of antioxidant and defoamer, and ball mill for 48 hours to obtain a mixed slurry;

[0037] 3) The agglomerated powder was prepared by centrifugal spray drying, wherein the inlet temperature was 210°C, the outlet temperature was 110°C, the rotation speed of the atomizing disc was 12000 / min, and the feeding volume was 300ml / min;

[0038] 4) Heat the powder in a vacuum degumming furnace, the sintering temperature is 1330°C, keep it warm for 3 hours, and then cool it to below 150°C with the furnace;

[0039]5) After sieving and grading the above-mentioned discharged powder, a powder suitable for sprayi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com