Polypropylene composition and flame-retardant antistatic pipe

A polypropylene composition, flame retardant and antistatic technology, applied in the field of polymers, can solve the problems of poor flame retardancy, poor antistatic performance, and decline in mechanical and mechanical properties of pipe products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

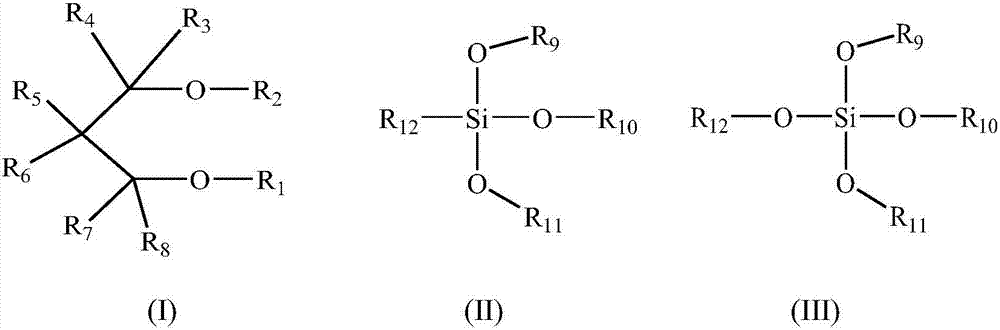

Method used

Image

Examples

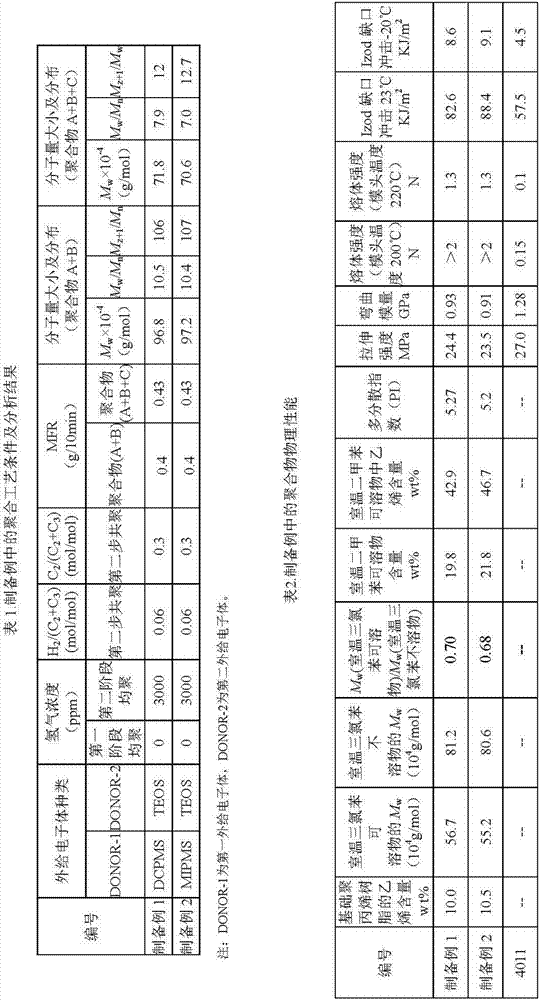

preparation example 1

[0094] This preparation example is used to illustrate the basic polypropylene resin provided by the present invention and its preparation method.

[0095] The propylene polymerization reaction is carried out on a polypropylene unit, and the main equipment of the unit includes a prepolymerization reactor, a first loop reactor, a second loop reactor and a third gas phase reactor. The polymerization method and steps are as follows.

[0096] (1) Prepolymerization reaction

[0097] The main catalyst (DQC-401 catalyst, provided by Sinopec Catalyst Company Beijing Aoda Branch), the cocatalyst (triethylaluminum), the first external electron donor (dicyclopentyl-dimethoxysilane, DCPMS) after 6 ℃, 20min after pre-contact, continuously into the continuous stirred tank prepolymerization reactor for prepolymerization reactor. The flow rate of triethylaluminum (TEA) entering the prepolymerization reactor is 6.33g / hr, the flow rate of dicyclopentyl-dimethoxysilane is 0.3g / hr, the flow rate...

preparation example 2

[0105] This preparation example is used to illustrate the basic polypropylene resin provided by the present invention and its preparation method.

[0106] The catalyst used in Preparation Example 2, pre-complexation, and polymerization process conditions are the same as those in Preparation Example 1. The difference with Preparation Example 1 is: the amount of hydrogen in the second reactor in the second stage becomes 13000ppm, and the hydrogen in the second step gas phase reactor 2 / (C 2 +C 3 ) was adjusted to 0.49 (mol / mol). The first external electron donor was changed to methyl-isopropyl-dimethoxysilane (MIPMS), and the amount added remained unchanged. The obtained polymer analysis results and polymer physical properties are listed in Table 1 and Table 2.

[0107] It can be seen from the results shown in Table 1 and Table 2 that the polypropylene material prepared according to the method of the present invention has high melt strength and relatively high high and low t...

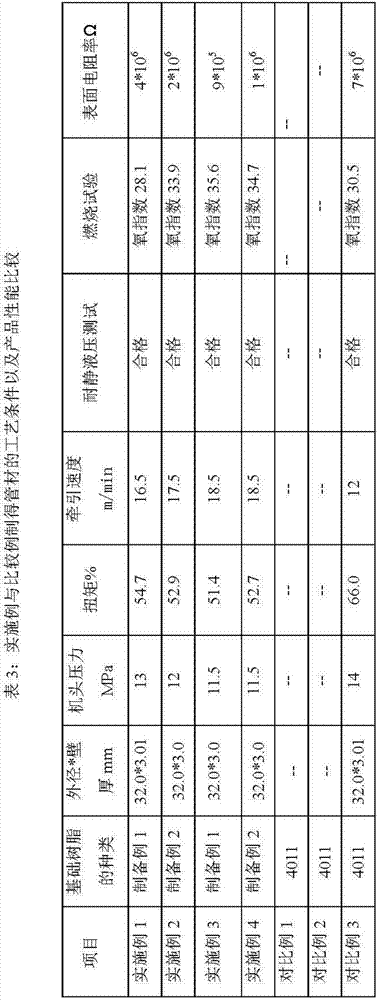

Embodiment 1

[0109] This example is used to illustrate the polypropylene composition and the flame-retardant and antistatic PP-H pipe provided by the present invention.

[0110] The polypropylene composition provided in this example contains Preparation Example 1, a halogen-free flame retardant, a conductive filler and a lubricant.

[0111] The halogen-free flame retardant is superfine aluminum hydroxide by precipitation method, produced by Jinan Taixing Company, with a particle size of 500-800nm.

[0112] The conductive filler is acetylene carbon black, purchased from Tianjin Lihuajin Chemical Co., Ltd.;

[0113] The lubricant is a PEG lubricant produced by Clariant, Switzerland, with a weight-average molecular weight of 10,000.

[0114] (1) Preparation of polypropylene composition:

[0115] The above-mentioned components were weighed and mixed according to the proportion, wherein the preparation example 1 was 100kg, the halogen-free flame retardant was 40kg, the conductive filler was 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com