Automatic production equipment control system and control method for realizing chip filling

A technology of production equipment and control system, which is applied in the control system and control field of automatic production equipment for realizing chip filling, and can solve the problems of single key, hidden danger and error-prone.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

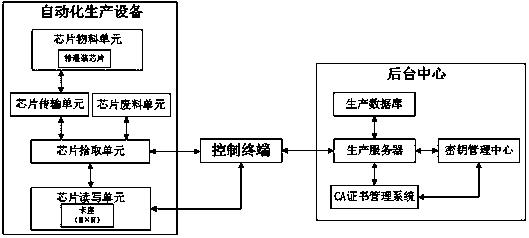

[0063] Such as figure 1 As shown, an automatic production equipment control system for chip filling, including automatic production equipment, a control terminal and a background center;

[0064] The automated production equipment includes a chip material unit, a chip transfer unit, a chip waste unit, a chip pick-up unit, and a chip read-write unit; the chip material unit includes chips to be filled; the chip read-write unit includes M×N cards seat, M represents the number of decks in one row in the chip read-write unit, and N represents the number of decks in a row in the chip read-write unit; the background center includes a production database, a production server, and is used to generate chip numbers CA certificate management system for certificates and key management center for generating chip keys;

[0065] The material unit is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com