PCB and PCBA

A groove bottom and solder paste technology, which is applied to printed circuits, printed circuits connected with non-printed electrical components, electrical components, etc., can solve problems such as virtual soldering, large amount of solder paste 4', and poor control of the amount , to achieve the effect of ensuring the overall structural strength, improving heat dissipation efficiency, and increasing installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a PCB 1, including a first groove 2 and a second groove 3, wherein the first groove 2 is a non-metallized groove, which is set on one side of the PCB 1, and the second groove 3 The groove bottom of the first groove 2 is opened, the groove bottom and the groove wall of the second groove 3 are metallized, and the solder paste 4 is arranged in the second groove 3 .

[0042] In this embodiment, the PCB 1 is formed by pressing three core boards, but the number is not limited thereto, for example, two or four core boards can also be formed by pressing together. Before pressing, at least one prepreg is stacked between two adjacent core boards, and the number of prepregs is selected according to the actual pressing situation.

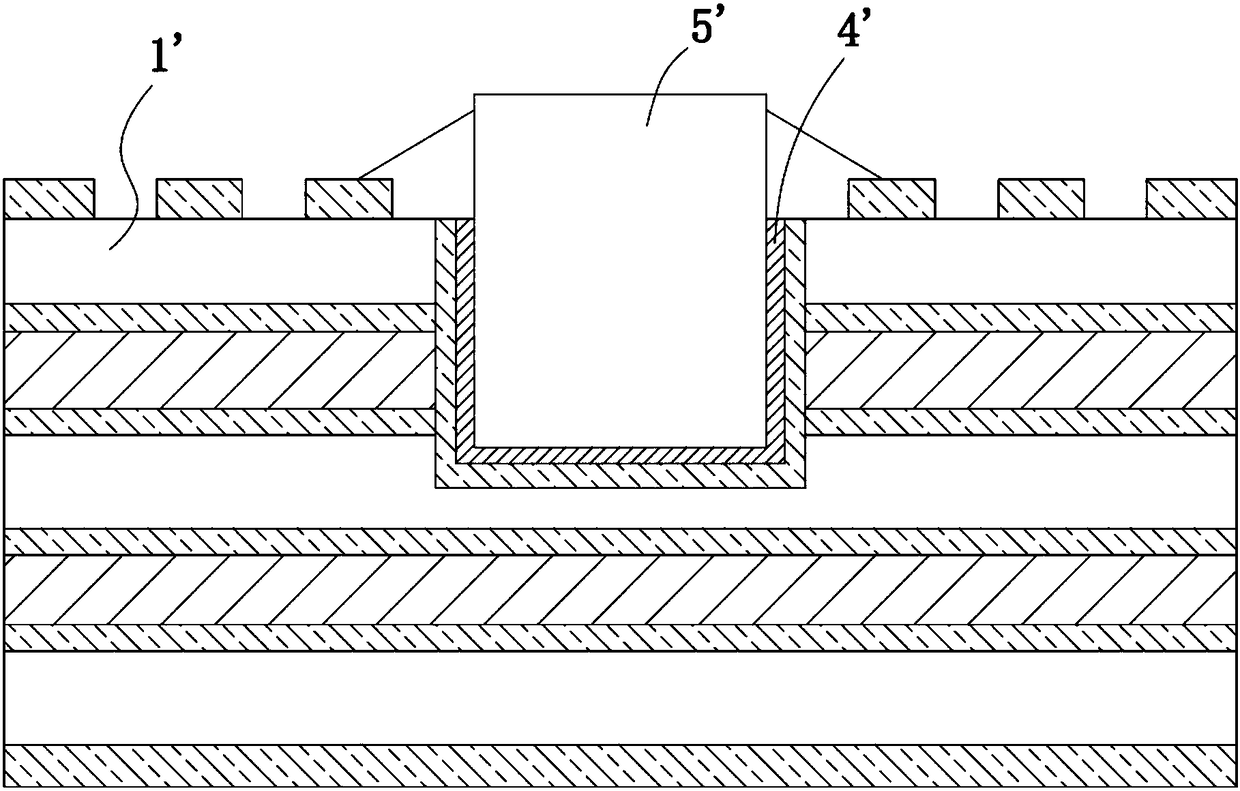

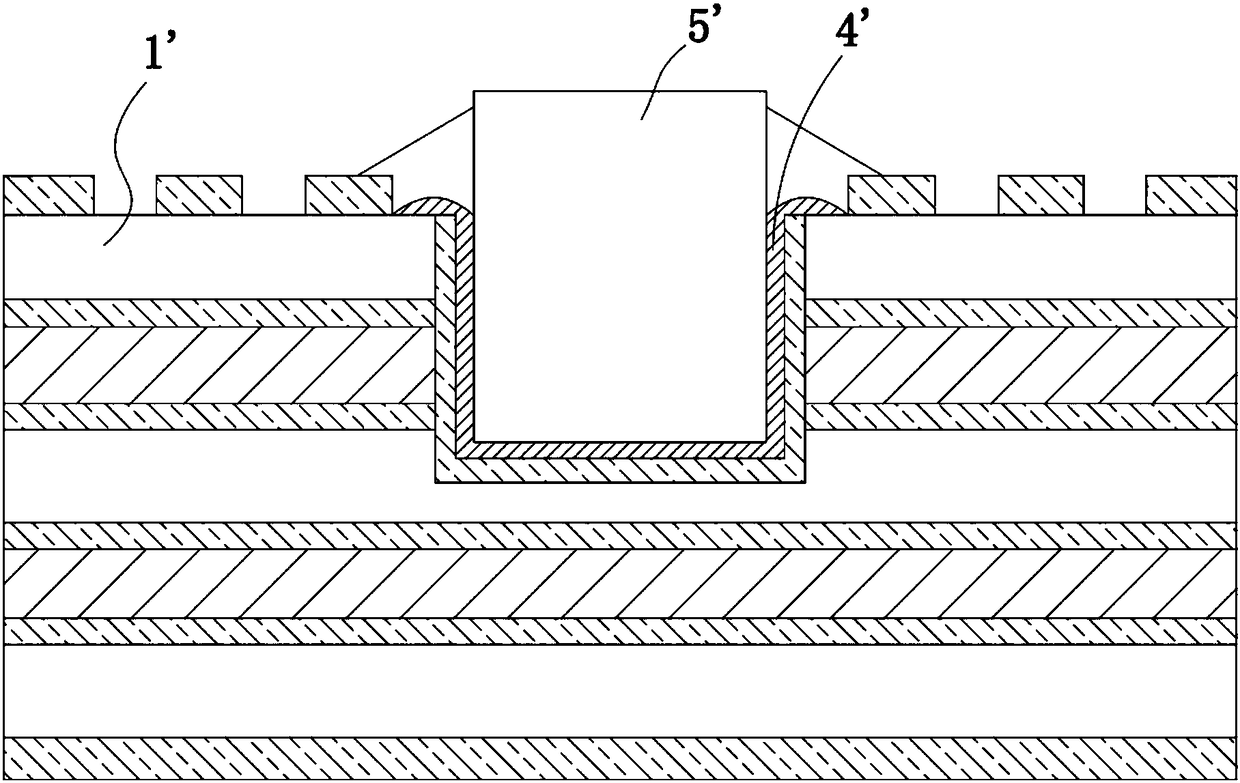

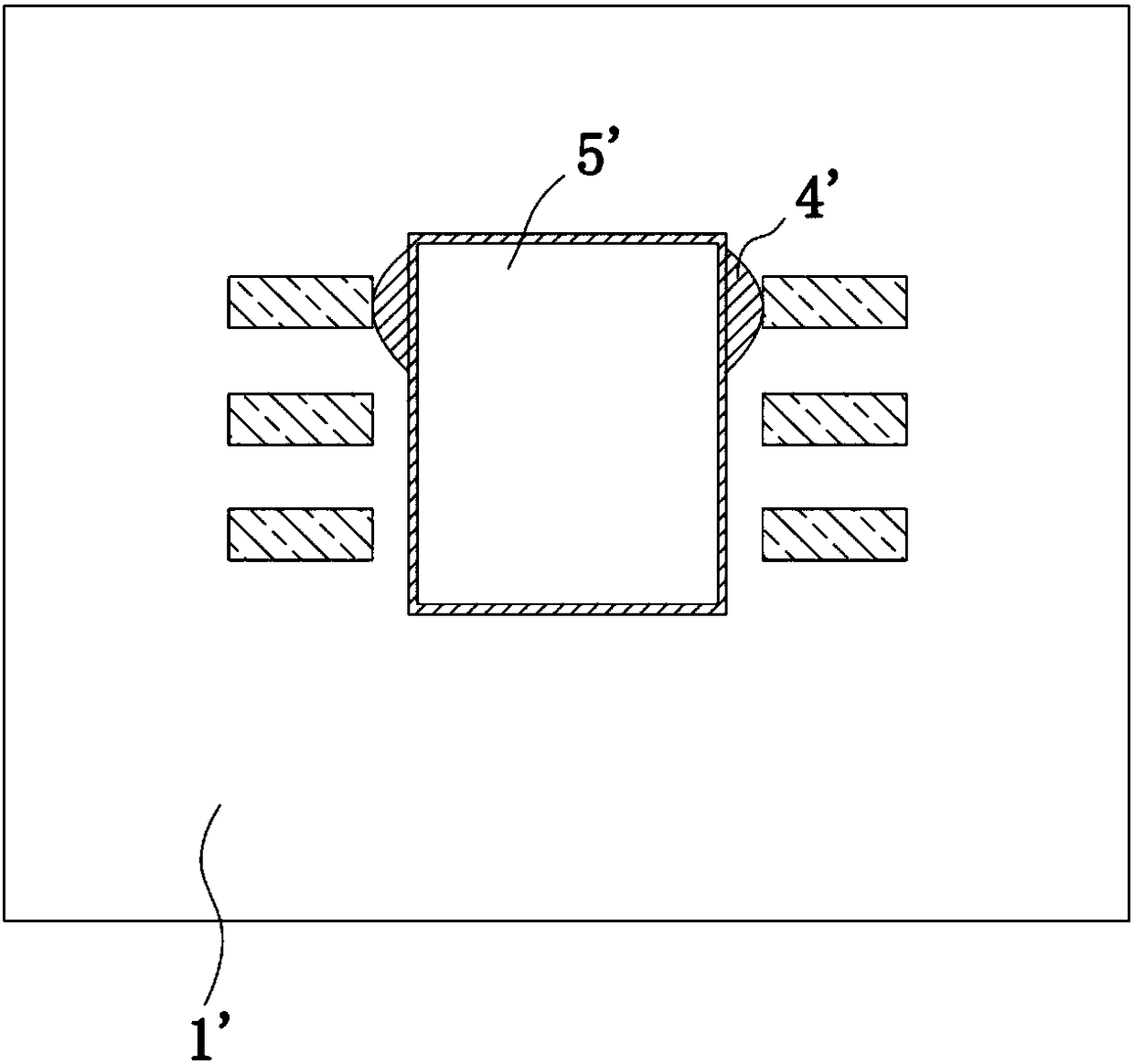

[0043] This embodiment also provides a PCBA (Printed Circuit Board+Assembly), such as Figure 4-Figure 6 As shown, the PCBA includes components 5 and the PCB 1 provided in this embodiment. The components 5 are welded in the seco...

Embodiment 2

[0069] This embodiment provides a PCB 1 , which is basically the same as the first embodiment, and for the sake of brevity, only the differences between this embodiment and the first embodiment will be described. The structure of the first groove 2 in this embodiment is different from the first embodiment.

[0070] Such as Figure 7 As shown, the first groove 2 includes a middle groove 21 and several extension grooves 22, the second groove 3 is set at the groove bottom of the middle groove 21, and the horizontal cross-sectional area of the second groove 3 is smaller than the horizontal cross-sectional area of the middle groove 21 , a number of extension grooves 22 are arranged at intervals around the middle groove 21 and are all connected to the middle groove 21. The opening positions of the extension grooves 22 are selected according to the distribution of the circuit patterns on the surface layer of the PCB. Specifically, the extension grooves 22 avoid The circuit patte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com