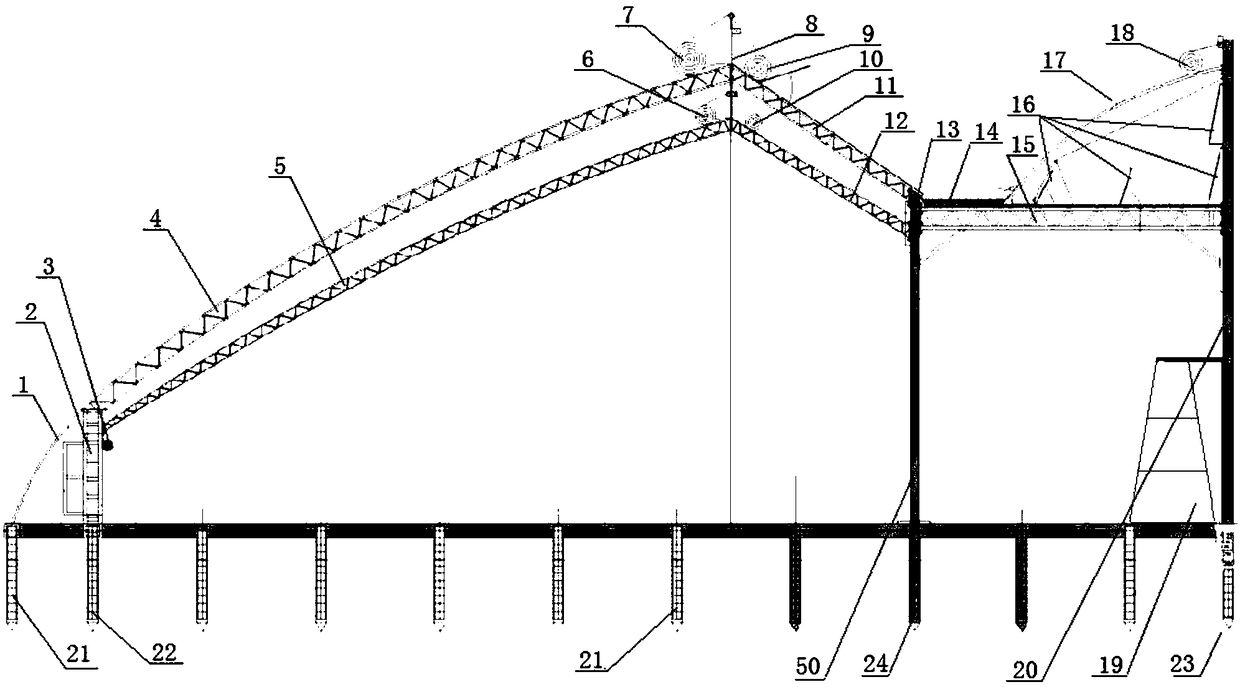

Super-span superposed high-energy greenhouse and setup method thereof

A super-span stacked, greenhouse technology, applied in agricultural facilities and solar greenhouses, can solve the problems of low light transmittance, insufficient heat storage energy, and energy consumption of thermal insulation blankets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0120] Embodiment 3, the difference between this embodiment and Embodiment 2 is that the distance between the adjacent outer arches 4 and the adjacent inner arches 5 is 3m, and between the adjacent outer arches 4 Two auxiliary arches with a distance of 1m are respectively arranged between the adjacent inner arches 5, the lower ends of the auxiliary arches are fixedly connected with the first front ground beam 51 or the facade window frame 2, and the upper ends are connected with the insulation quilt pull-up frame. 8 fixed connections, the middle and longitudinal beams 35 fixed connections.

[0121] The distance between the adjacent outer rear slopes 11 and the adjacent inner rear slopes 12 is 3m, and the adjacent outer rear slopes 11 and the adjacent inner rear slopes 12 are respectively set Two auxiliary rear slope frames with a distance of 1m, the lower end of the auxiliary rear slope frame is fixedly connected with the rear roof frame, the upper end is fixedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com