Glaze spraying device for ceramic products

A ceramic product and glaze spraying technology, which is applied in the field of ceramic product glaze spraying device, can solve the problems of high manufacturing cost and low manufacturing cost, and achieve the effects of low manufacturing cost, easy manufacturing and realization, and scientific and reasonable structure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

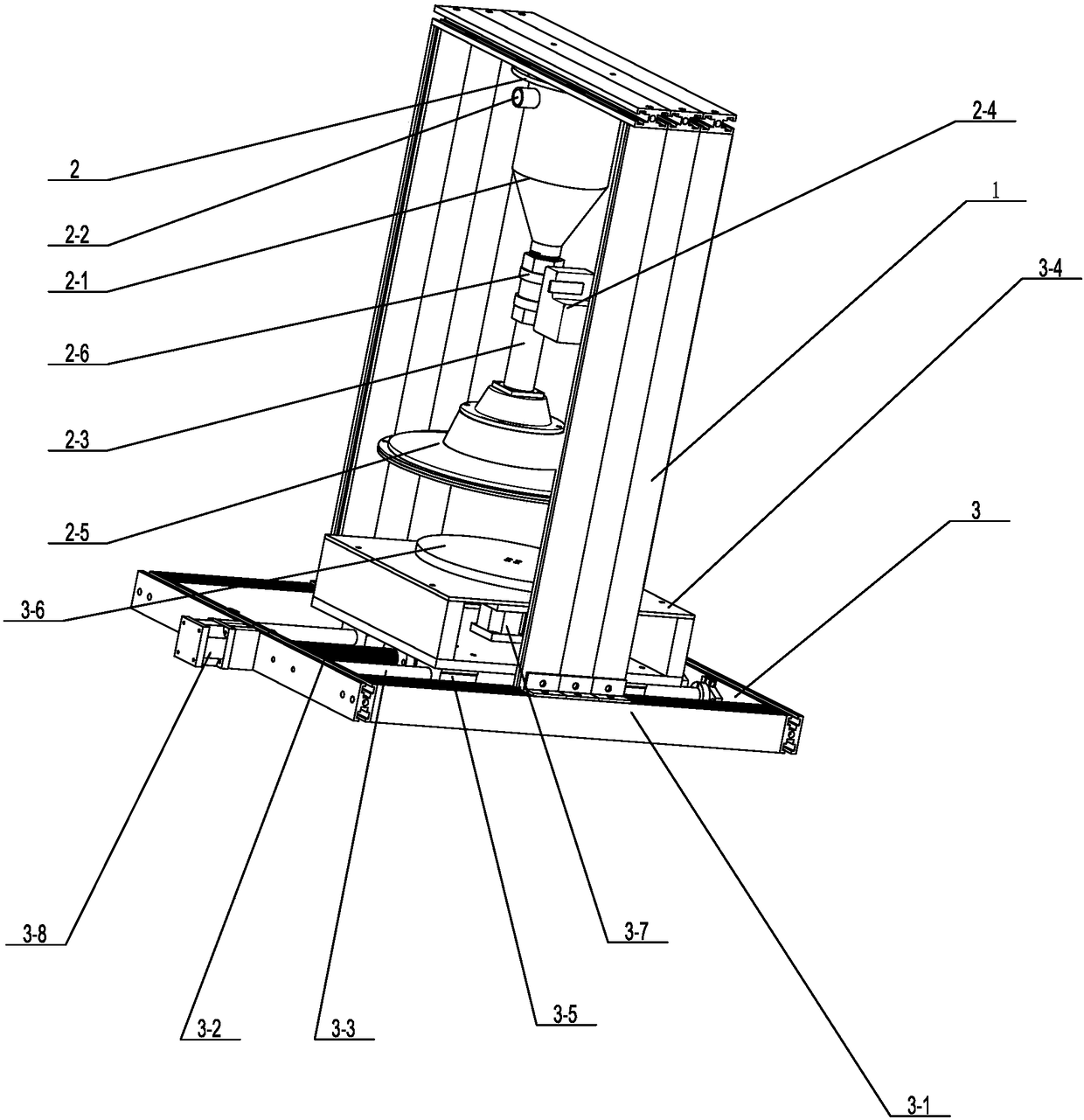

[0016] Such as figure 1 A specific embodiment of the present invention is proposed as shown in the figure. The glaze spraying device for ceramic products includes a frame-shaped, vertically arranged gantry crane 1. In this embodiment, the gantry crane 1 is set as a rectangular parallelepiped frame. The gantry crane 1 is equipped with an automatic glaze sprayer. Mechanism 2 and workbench rotation mechanism 3; the automatic glaze spraying mechanism 2 includes a glaze storage cylinder 2-1 fixed on the top of the gantry crane 1. In this implementation, the glaze storage cylinder 2-1 is fixed on the top of the gantry crane 1 through a bolt set. The upper end of the glaze storage cylinder 2-1 is provided with a glaze filling interface 2-2, the glaze filling interface 2-2 is connected to the glaze supply system, and the bottom end of the glaze storage cylinder 2-1 is connected to the A glaze conveying pipe 2-3, the glaze conveying pipe 2-3 is set vertically downward, and a control va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com