Simple-to-splice waterproof wood floor and manufacturing technology

A technology for manufacturing process and wooden floor, which is applied in the field of waterproof wooden floor and manufacturing process, can solve the problems of high cost and complicated method, and achieve the effects of low VOC, improved mechanical strength and improved mold release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

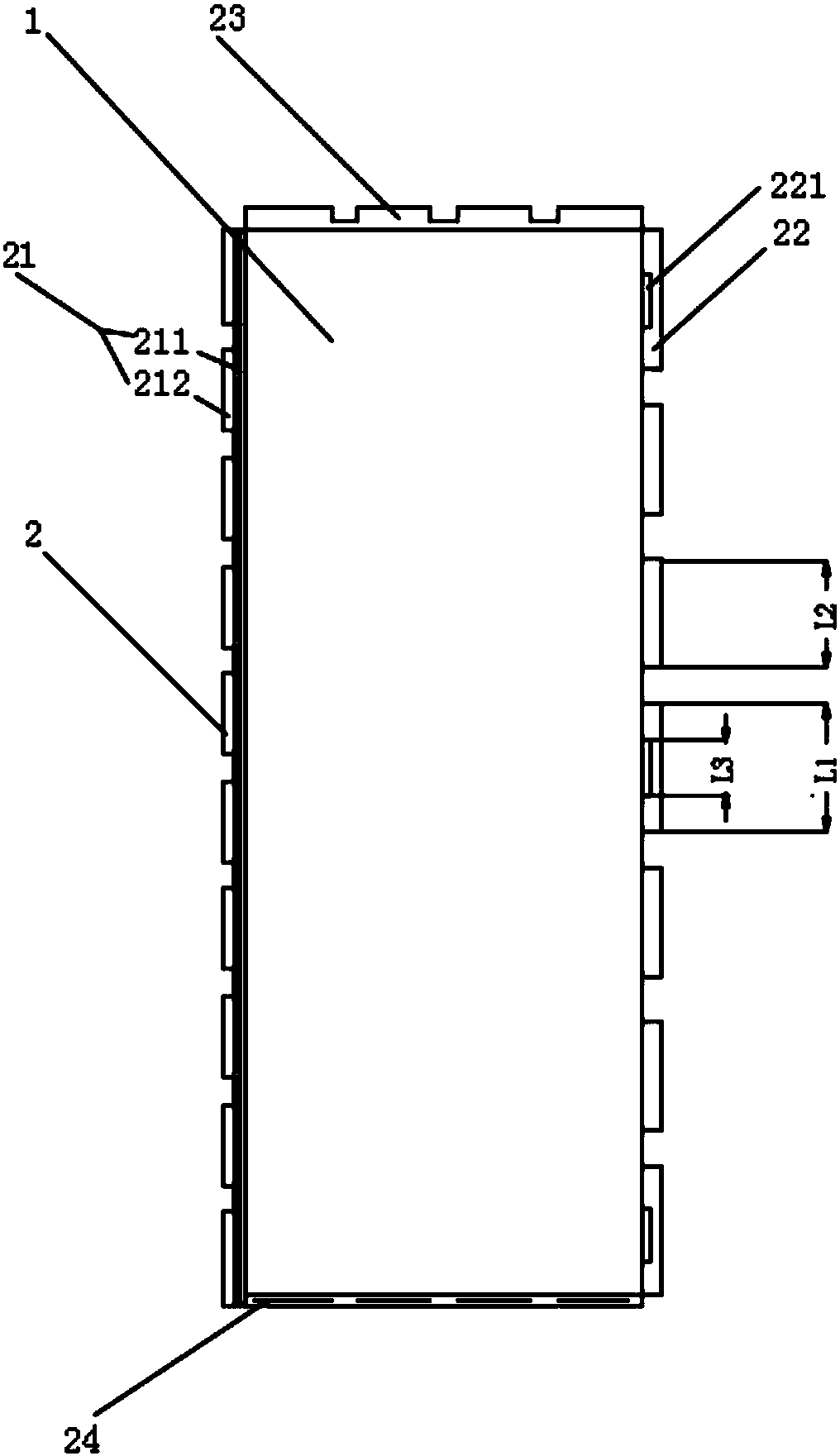

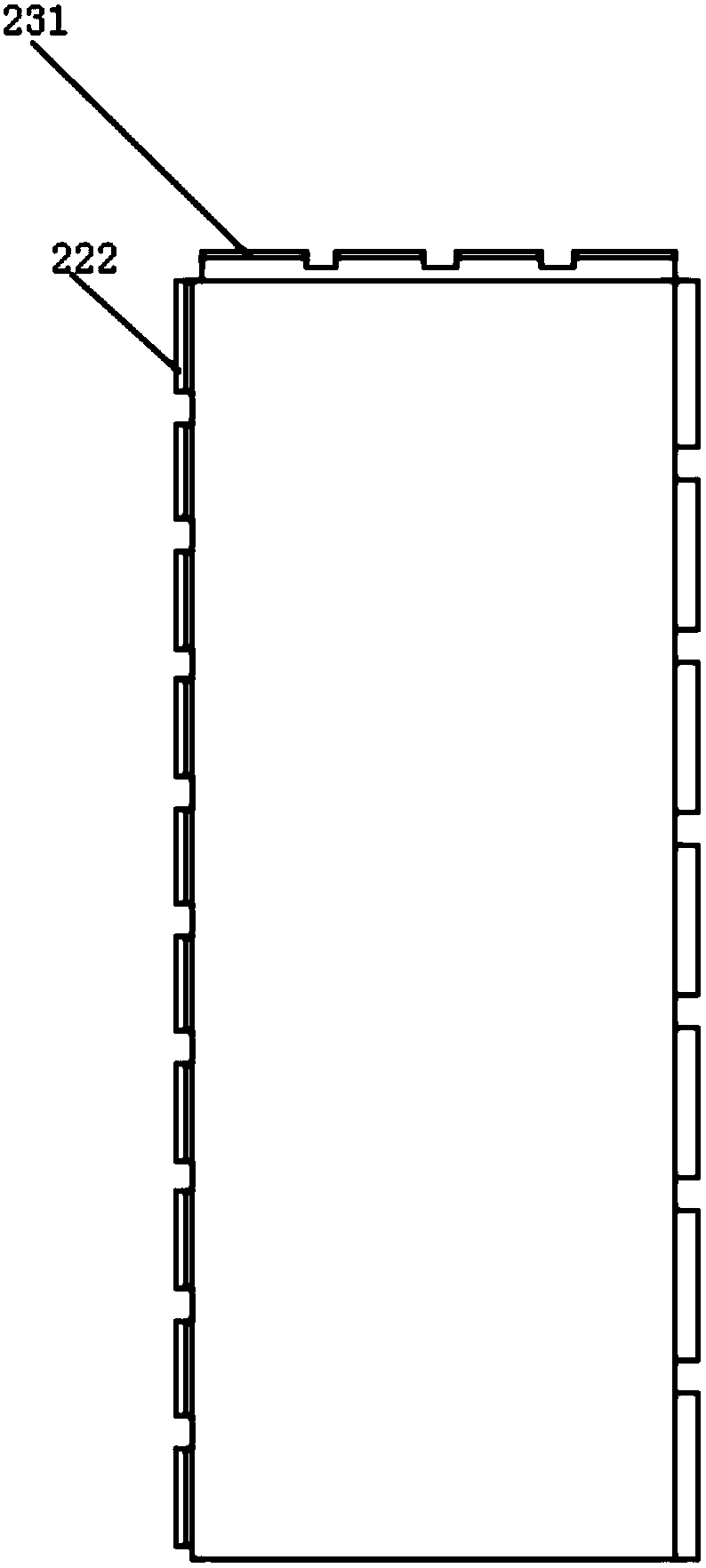

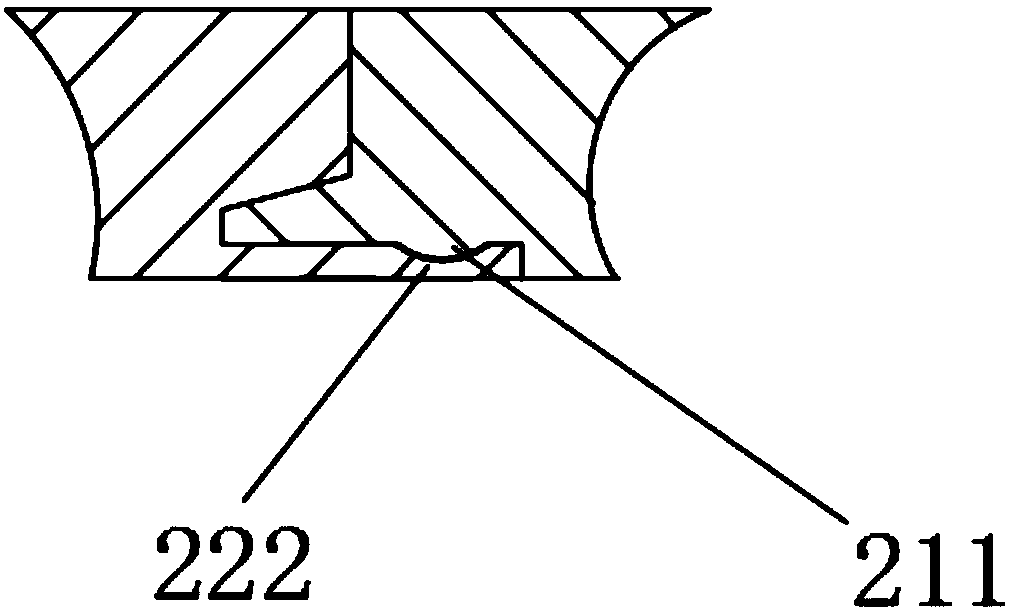

[0043] Roll-coat the two-component polyurethane adhesive on the upper and lower surfaces of the low-density particle board, and the application amount is 100g / m 2 , a layer of LVT veneer is pasted on the upper surface, a layer of PVC veneer is pasted on the lower surface, and the pressure on the cold press is 30kg / cm 2 Carry out cold pressing and lamination for 4h. Saw and cut for health preservation, open T-shaped groove, put it in the injection mold, at the temperature of 180-190°C, the time is 22s, and the injection pressure is 80kg / cm 2 Lower the polypropylene frame with injection molded edge banding and locking fasteners to obtain a waterproof wooden floor 1, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 shown.

Embodiment 2

[0045] Roll-coat the two-component polyurethane adhesive on the upper and lower surfaces of the high-density particle board, and the application amount is 90g / m 2 , a layer of LVT veneer is pasted on the upper surface, a layer of PVC veneer is pasted on the lower surface, and the pressure on the cold press is 27kg / cm 2 Carry out cold pressing and lamination for 8 hours. Saw and cut for health preservation, open T-shaped groove, put it in the injection mold, at the temperature of 210-220°C, the time is 22s, and the injection pressure is 70kg / cm 2 Lower the ABS frame with injection molded edge banding and locking fasteners to get waterproof wooden floor 2, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 shown.

Embodiment 3

[0047] Roll-coat two-component polyurethane adhesive on the upper and lower surfaces of the low-density board, and the construction amount is 100g / m2 2 , a layer of LVT veneer is pasted on the upper surface, a layer of PVC veneer is pasted on the lower surface, and the pressure on the cold press is 30kg / cm 2 Carry out cold pressing and lamination for 6h. Saw and cut for health preservation, open T-shaped groove, put it in the injection mold, at a temperature of 180-190°C, for 22s, and an injection pressure of 60kg / cm 2 Lower the PVC frame with injection molded edge banding and buckle to get waterproof wooden floor 3, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com