A method for the preparation of graphene oxide film assisted by gas stripping

A graphene film and fossil technology, applied in the field of gas-assisted rapid film formation, can solve the problems of time-consuming, toxic hydrogen iodide, and difficult transfer of graphene oxide film, etc., and achieve the effect of simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Add graphene oxide and ferric chloride to 50ml of deionized water, and disperse evenly. The resulting dispersion has a concentration of graphene oxide of 0.5ug / ml and a concentration of ferric chloride of 5mg / ml;

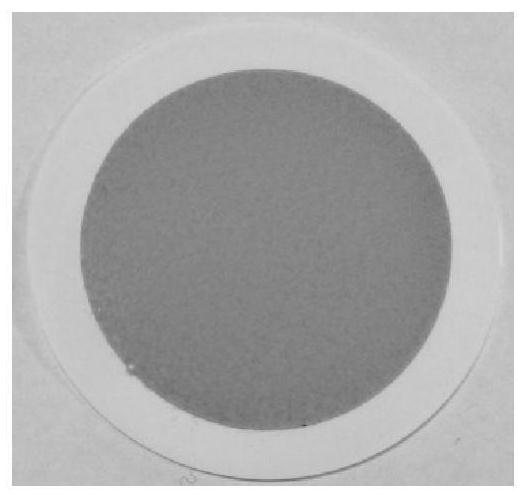

[0020] 2. Suction filter the above dispersion liquid to form a membrane. The pore size of the filter paper is 0.22um. See figure 1 ;

[0021] 3. Dry the above-mentioned filter paper with graphene oxide, and at this time, ferric chloride will recrystallize and separate out;

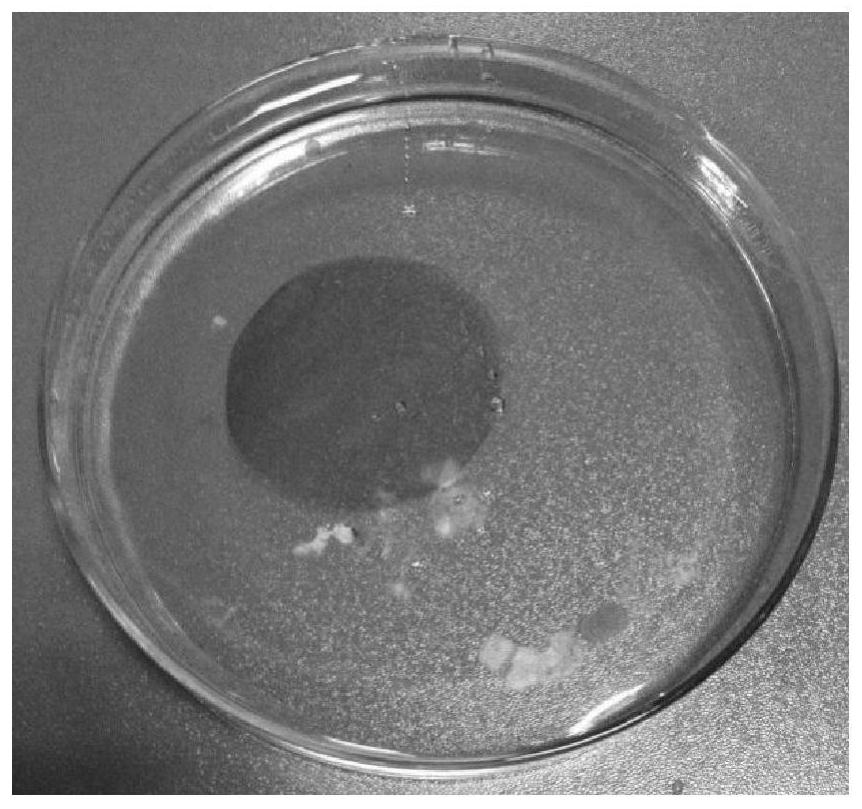

[0022] 4. Put the dried filter paper into the solution of hydrogen peroxide. At this time, the hydrogen peroxide will generate oxygen under the catalysis of ferric chloride, thereby peeling off the graphene oxide from the filter paper. See figure 2 , the graphene oxide film is complete;

[0023] 5. Put the target substrate in the above-mentioned hydrogen peroxide solution, pick up the graphene oxide film, and realize the transfer process.

Embodiment 2

[0025] The specific method is the same as in Example 1, except that the concentration of graphene oxide is 10 ug / ml, and the concentration of ferric chloride is 0.5 mg / ml.

Embodiment 3

[0027] The specific method is the same as in Example 1, except that the concentration of graphene oxide is 20ug / ml, and the concentration of ferric chloride is 10mg / ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com