A method and product for improving the microstructure and mercury removal performance of magnetic beads in fly ash

A technology with microstructure and mercury removal performance, applied in chemical instruments and methods, other chemical processes, physical/chemical process catalysts, etc., can solve problems such as easy agglomeration of active substances, limited loading of active substances, and decreased catalytic activity. Achieve the effects of improving the microstructure of magnetic beads, improving adsorption performance, and saving dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method of improving the microstructure and mercury removal performance of magnetic beads in fly ash according to this embodiment, the specific steps of the method are as follows:

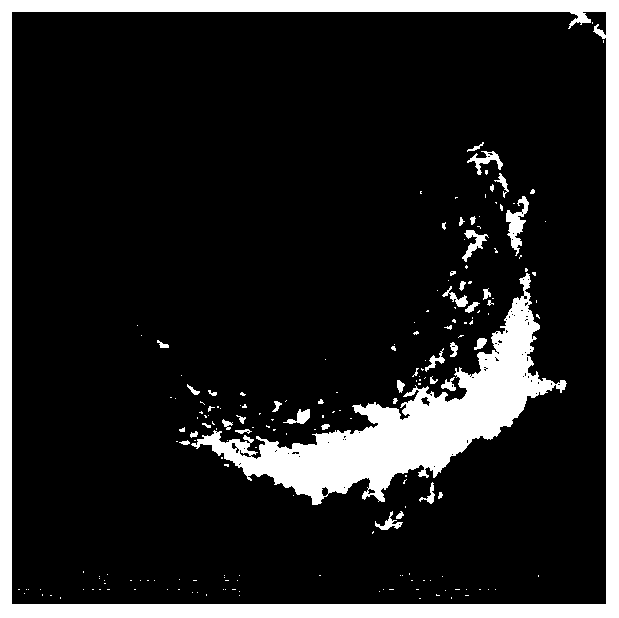

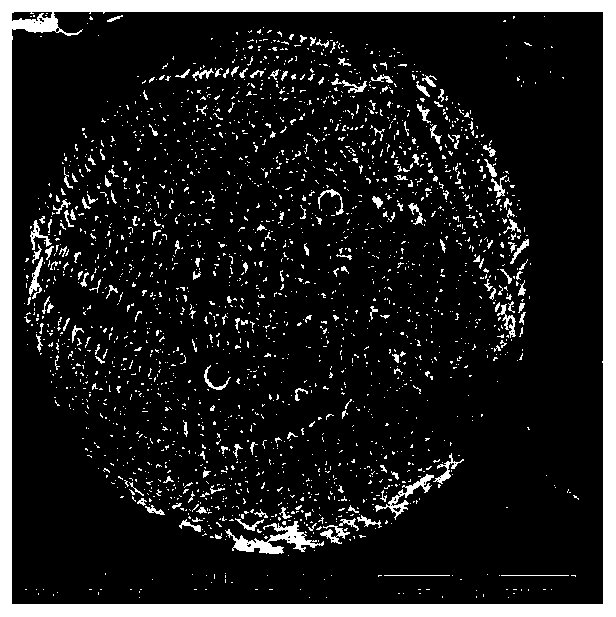

[0042] (1) Magnetic beads are separated from the fly ash by a magnetic separator, and the magnetic beads with a suitable particle size are screened out as a carrier with a 200-mesh standard after grinding;

[0043] (2) The chemical composition of the magnetic beads was tested by XRF. The silicon content in the magnetic beads was 27.8%, and the aluminum content was 20.4%. Weigh 2g of magnetic beads and place them in a polytetrafluoroethylene container;

[0044] (3) According to the ratio of HF solution to magnetic beads is 15ml / g, add 30ml concentration of 5% HF solution;

[0045] (4) Mechanical stirring for 20 minutes;

[0046] (5) Filter out the magnetic bead particles impregnated with HF solution, and wash several times with deionized water;

[0047] (6) Dry at 105° C. for 12 hours to ...

Embodiment 2

[0051] A method of improving the microstructure and mercury removal performance of magnetic beads in fly ash according to this embodiment, the specific steps of the method are as follows:

[0052] (1) Magnetic beads are separated from the fly ash by a magnetic separator, and the magnetic beads with a suitable particle size are screened out as a carrier with a 200-mesh standard after grinding;

[0053] (2) The chemical composition of the magnetic beads was tested by XRF. The silicon content in the magnetic beads was 31.3%, and the aluminum content was 24.1%. Weigh 2g of magnetic beads and place them in a polytetrafluoroethylene container;

[0054] (3) According to the ratio of HF solution to magnetic beads is 15ml / g, add 30ml of 8% HF solution;

[0055] (4) Mechanical stirring for 25 minutes;

[0056] (5) Filter out the magnetic bead particles impregnated with HF solution, and wash several times with deionized water;

[0057] (6) Dry at 105° C. for 12 hours to obtain magneti...

Embodiment 3

[0061] A method of improving the microstructure and mercury removal performance of magnetic beads in fly ash according to this embodiment, the specific steps of the method are as follows:

[0062] (1) Magnetic beads are separated from the fly ash by a magnetic separator, and the magnetic beads with a suitable particle size are screened out as a carrier with a 200-mesh standard after grinding;

[0063] (2) The chemical composition of the magnetic beads was tested by XRF. The silicon content in the magnetic beads was 28.2%, and the aluminum content was 19.7%. Weigh 2g of magnetic beads and place them in a polytetrafluoroethylene container;

[0064] (3) According to the ratio of HF solution to magnetic beads is 20ml / g, add 40ml of 1% HF solution;

[0065] (4) Mechanical stirring for 5 minutes;

[0066] (5) Filter out the magnetic bead particles impregnated with HF solution, and wash several times with deionized water;

[0067] (6) Dry at 105° C. for 12 hours to obtain magnetic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com