Roll speed control method and device for passivation roll coater

A technology of roller speed control and roller coating machine, which is applied in the direction of coating, metal material coating process, hot dip coating process, etc., can solve the problem of dense passivation roll marks on strip steel, reduce production costs and ensure stability The effect of going straight and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

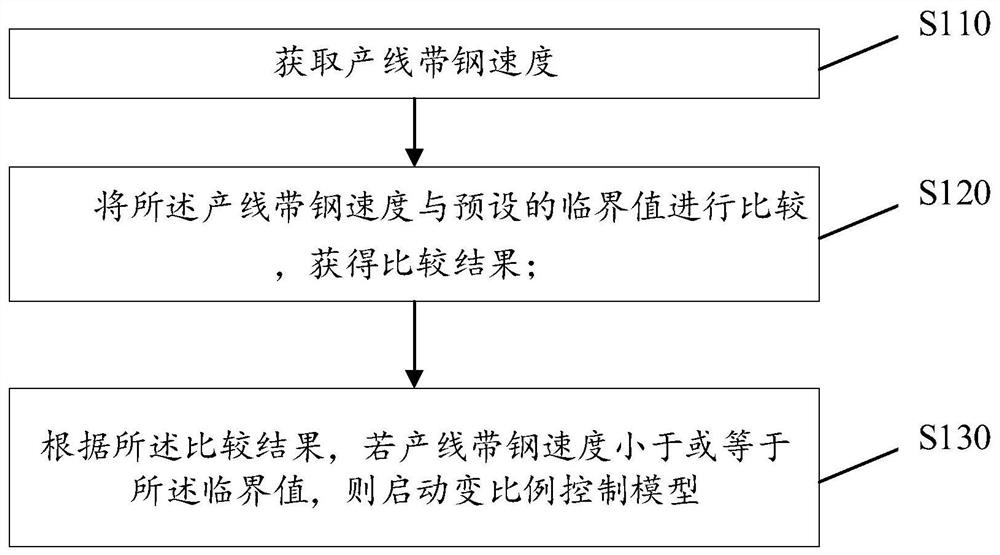

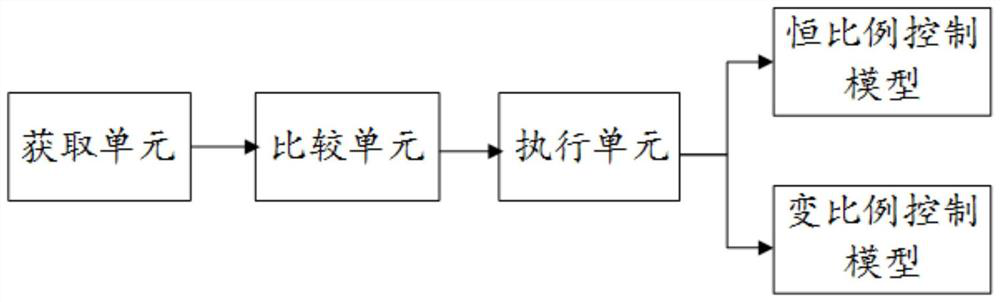

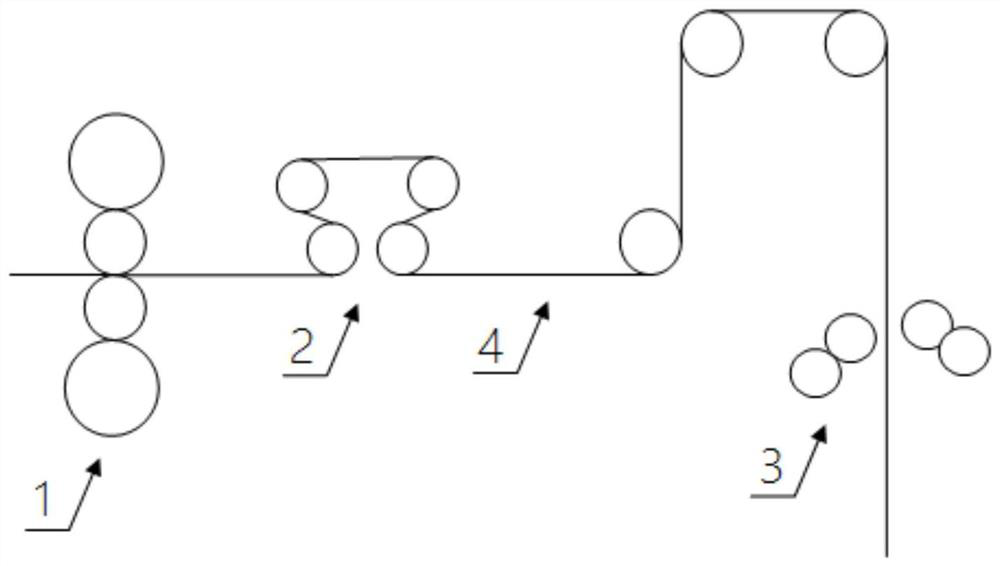

[0088] see image 3 , the hot-dip galvanizing production line passivation machine area roll system includes a skin pass machine 1, a tension roll group 2, a four-roll passivation machine 3, and a strip steel 4 passes through the skin pass machine 1, tension roll group 2 and Four roll passivation machine3. see Figure 4 , the four-roll passivation machine 3 includes an upper coating roll 41 , a lower coating roll 42 , an upper pick-up roll 43 and a lower pick-up roll 44 . see Figure 5 , in order to reduce the problem of dense passivation roll marks due to the low speed of passivation machine due to roll change or other abnormal conditions, this embodiment controls the roll speed of the four-roll passivation machine as follows:

[0089] The strip steel of the hot-dip galvanizing production line starts to run, the acquisition unit obtains the running speed of the strip steel, and the comparison unit compares the strip steel speed with the preset critical value, specifically: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com