Main rotor shaft of single rotor unmanned aerial vehicle and processing technology thereof

A technology of main rotor shaft and processing technology, which is applied in the direction of metal material coating technology, shaft, mechanical equipment, etc., can solve problems such as safety hazards, impact resistance, wear resistance, and service life limitations, so as to improve performance , Guarantee the effect of excellent quality and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

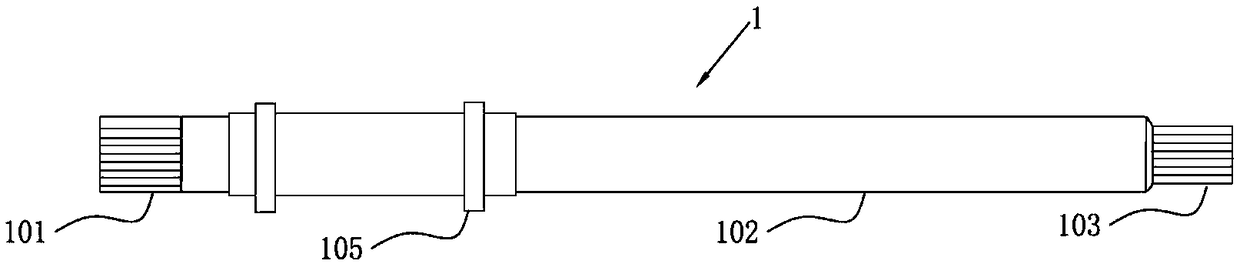

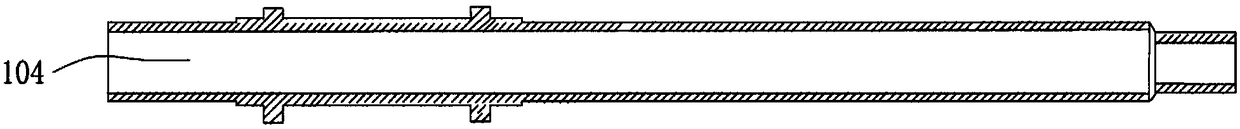

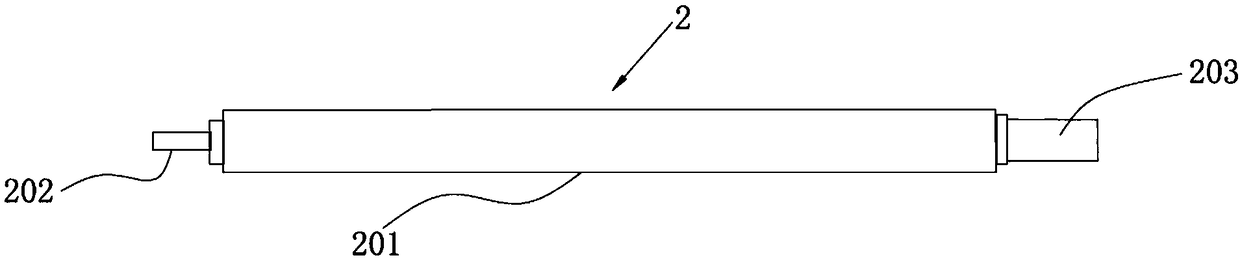

[0032] Such as Figure 1 to Figure 3 As shown, the main rotor shaft of a single-rotor UAV includes a main shaft 1 and an auxiliary shaft 2, the main shaft 1 and the auxiliary shaft 2 are cylindrical, and the main shaft 1 includes a shaft head 101 and a shaft body 102 and the shaft tail 103, the diameter of the shaft tail 103 is smaller than the diameter of the shaft body 102, the shaft head 101 and the shaft tail 103 are both spline shafts, and the main shaft 1 is provided with an inner hole 104 arranged along the direction of the central axis , the auxiliary shaft 2 includes a body 201 and a connecting portion 202 and a fixing portion 203 arranged at both ends of the body, the body 201 of the auxiliary shaft 2 is connected with the inner hole 104 through a transition fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com