LED quantum dot light emitting device and packaging method thereof

A quantum dot light-emitting, quantum dot technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problem of reducing the light conversion stability of quantum dot light conversion coatings, reducing the conversion efficiency of quantum dot light conversion coatings, and reducing device light. Effectiveness, CRI and service life, etc., to achieve high thermal reliability, avoid aging failure, and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0046] In order to facilitate a unified review of the various reference signs in the drawings of the specification, the unified description of the reference signs appearing in the drawings of the specification is as follows:

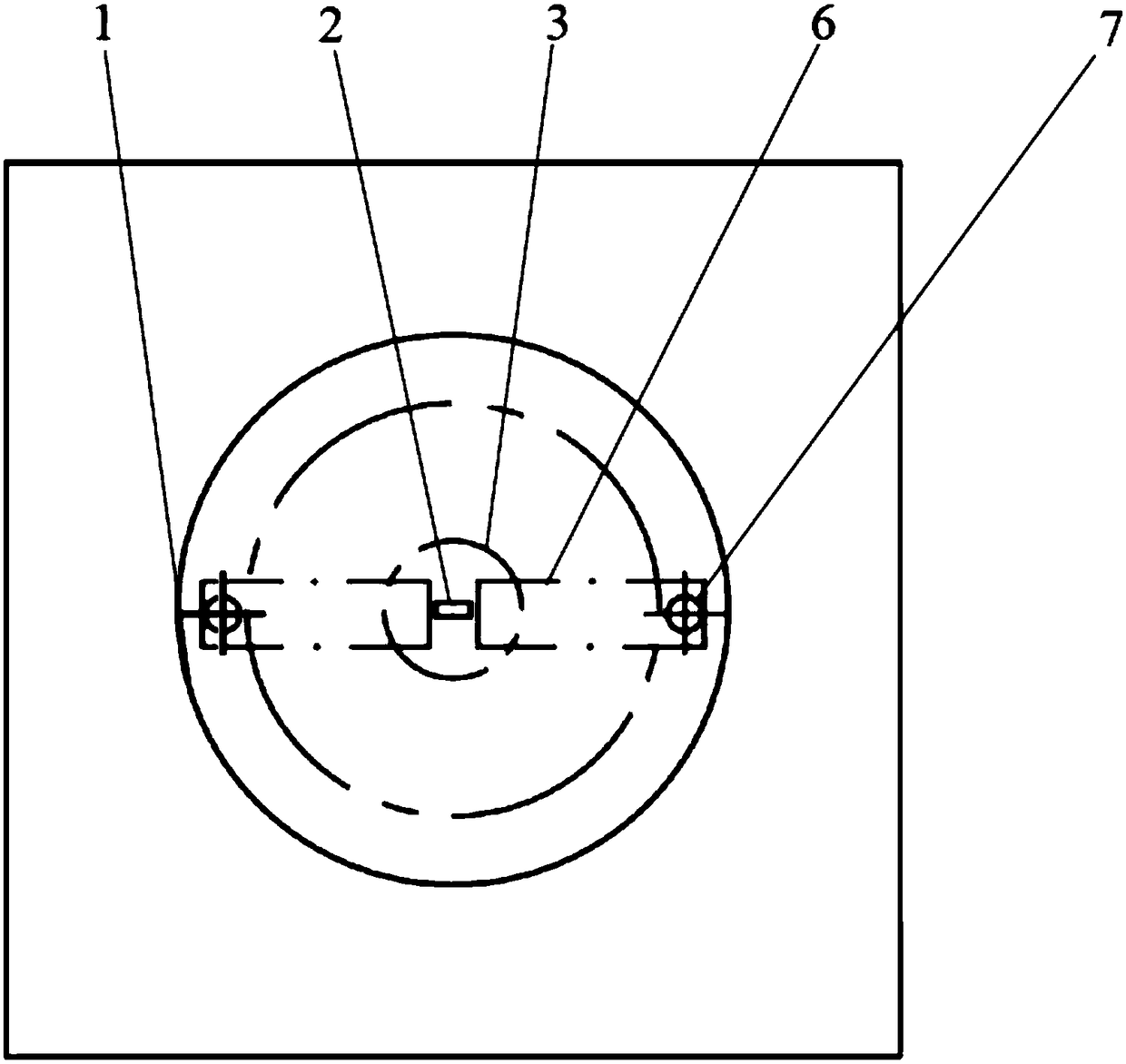

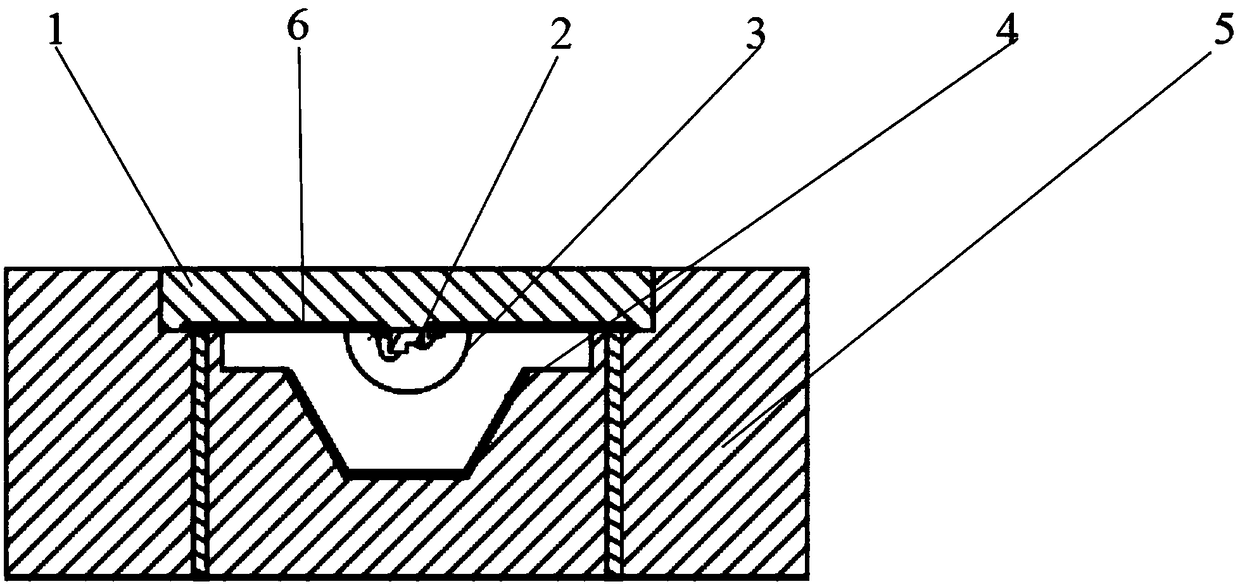

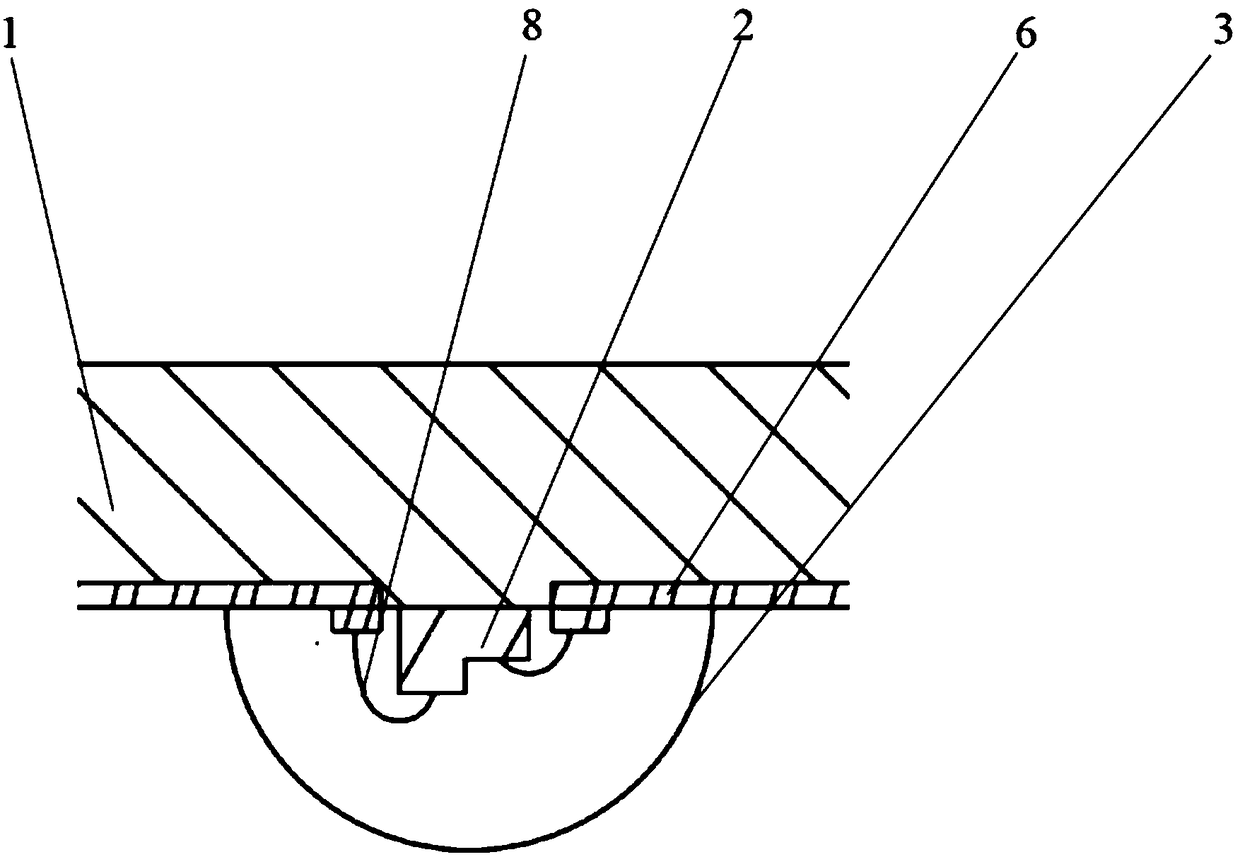

[0047] 1 is the glass top cover, 2 is the LED light-emitting chip with the formal structure, 3 is the light-taking lens, 4 is the quantum dot light conversion coating, 5 is the insulator high thermal conductivity support, 6 is the electrode metal layer, 7 is the electroplated copper column, 8 is the Lead wire, 9 is a flip-chip LED light-emitting chip, 10 is a metal conductor high thermal conductivity support, 11 is an insulating layer, 12 is a first plane, 13 is an inclined plane, 14 is a second plane, 15 is a first vertical plane, and 16 is a second plane. Three planes, 17 is the second vertical plane.

[0048] For ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com