Duplex winding dual-rotor motor and double-blade food processer

A dual-rotor motor, dual-winding technology, applied to synchronous motors with stationary armatures and rotating magnets, electromechanical devices, electrical components, etc. The effect of strong applicability and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

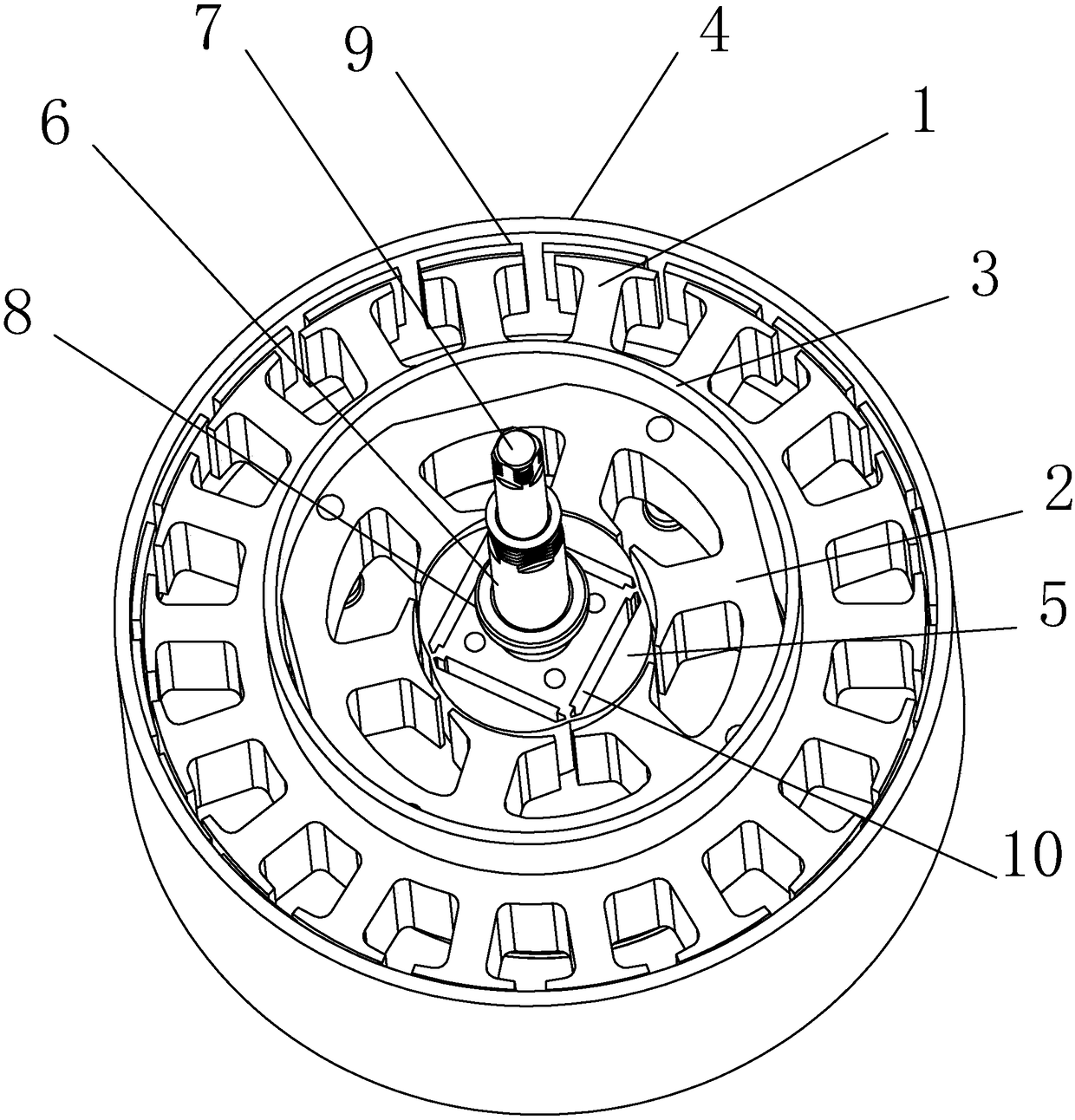

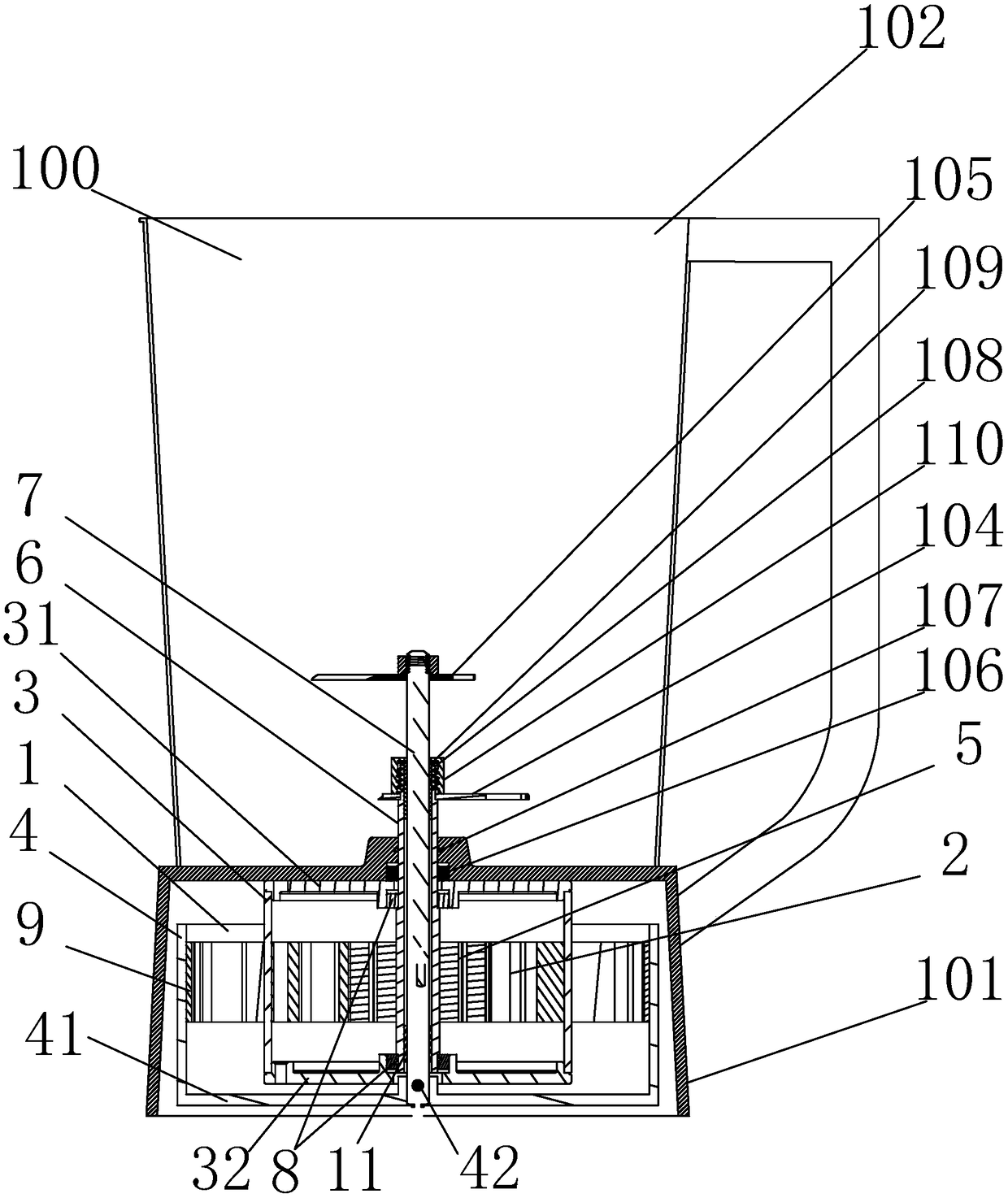

[0019] refer to figure 1 , a double-winding double-rotor motor of the present invention includes a hollow outer stator 1, an inner stator 2 is arranged inside the outer stator 1, and the outer stator 1 and the inner stator 2 are separated by a middle shell 3, the The outer stator 1 is sleeved with an outer rotor 4, and the inner stator 2 is provided with an inner rotor 5. The double-winding double-rotor motor also includes a large shaft 6 and a small shaft 7 whose axes coincide. The inside of the large shaft 6 is Hollow and sleeved on the periphery of the small shaft 7, the outer rotor 4 is connected with the small shaft 7 and drives the small shaft 7 to rotate, and the inner rotor 5 is connected with the large shaft 6 and drives the large Axis 6 rotates. The outer stator 1 and inner stator 2 are independent of each other and separated by the middle shell 3. The outer stator 1 is socketed outside the inner stator 2. The height of the motor can be made very short, and the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com