Multi-temperature-stage-controlled after-ripening and fermenting technology of bean halves in Pixian county

A post-ripening fermentation and multi-temperature section technology, applied in food science and other fields, can solve problems such as uneven reaction, failure to consider the influence of moisture, and affect product flavor and taste, so as to improve product quality and safety, and reduce miscellaneous bacteria Opportunity for contamination, full-bodied effect of complex flavors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

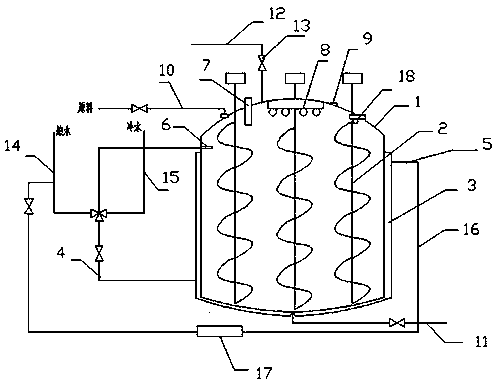

[0046] Present embodiment ferments with fully enclosed fermentor, and the concrete structure of fermentor is:

[0047] The fermenter includes a tank body 1 and a stirring paddle 2, the stirring paddle 2 is at least two, the stirring paddle 2 is installed in the tank body 1, the tank body 1 is equipped with a jacket layer 3, and the jacket layer 3 is connected with a water inlet pipe 4 And outlet pipe 5, temperature detector 6, humidity detector 7, ultraviolet lamp and fluorescent lamp 8 are installed in tank body 1, and tank body 1 is provided with inlet, outlet, sterile dry air inlet and exhaust Air port 9, feed port is connected with feed pipe 10, discharge port is connected with discharge pipe 11, sterile dry air inlet is connected with air intake pipe 12, feed pipe 10, discharge pipe 11, air intake pipe 12 Both are connected with valve 13.

[0048] Also includes a controller (not shown in the figure), the controller is connected with the temperature detector 6, the humidi...

Embodiment 2

[0064] The fermentation tank that this implementation adopts is identical with embodiment 1, and difference is:

[0065] The process of this embodiment is:

[0066] Step 1, raw materials into the tank

[0067] Weigh 70kg of fermented mature pepper embryos and 30kg of sweet petals, and then add the weighed pepper embryos and sweet petals into the fermenter;

[0068] Step 2, initial fermentation

[0069] Let the controller control the amount of hot water and cold water entering the water inlet pipe to control the temperature of the fermenter to 30°C. After 12 hours of heat preservation and fermentation, add salt to the reactor. The amount of added salt is 1% of the total mass. 18%;

[0070] Step 3, mid-term fermentation

[0071]After the initial fermentation, 14 cycles of mid-stage fermentation are carried out. The mid-stage fermentation operation of each cycle is as follows: first, the fermentation temperature is raised to 55°C, and the fermentation is kept for 6 hours, and...

Embodiment 3

[0077] The fermentor that this implementation adopts is identical with embodiment 1, and difference is:

[0078] The process of this embodiment is:

[0079] Step 1, raw materials into the tank

[0080] Weigh 70kg of fermented mature pepper embryos and 25kg of sweet petals, and then add the weighed pepper embryos and sweet petals into the fermenter;

[0081] Step 2, initial fermentation

[0082] Let the controller control the amount of hot water and cold water entering the water inlet pipe to control the temperature of the fermenter to 26°C. After 15 hours of heat preservation and fermentation, add salt to the reactor. The amount of added salt is 15% of the total mass. %;

[0083] Step 3, mid-term fermentation

[0084] After the initial fermentation, 12 cycles of mid-stage fermentation are carried out. The mid-stage fermentation operation of each cycle is as follows: first, the fermentation temperature is raised to 52°C, and the fermentation is kept for 8 hours, and then th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com