Sea cucumber protein solid beverage filtering equipment

A technology of solid beverage and sea cucumber protein, which is applied in the direction of solid separation, separating solid from solid with airflow, and filtering and sieving. It can solve the problems of raw material agglomeration, affecting the quality of solid beverage, and appearance of impurities, so as to improve quality, Reduce processing energy consumption and equipment costs, the effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

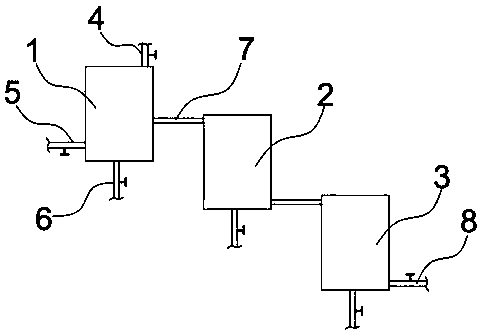

[0021] like figure 1 As shown, the sea cucumber protein solid beverage filtration equipment includes a primary filter tank 1 connected to a feed pipe 4 at the top, an intermediate filter tank 2 and a precision filter tank 3 connected to a discharge pipe 8 at the bottom, and a transmission tank is passed between each filter tank 7 connections, the height positions of the primary filter tank 1, the intermediate filter tank 2 and the precision filter tank 3 are successively decreased. The present invention respectively sets primary, intermediate and precision filter tanks to gradually filter the solid beverage raw materials, and gradually remove impurities and impurities in the raw materials. Agglomerated substances greatly improve the quality of raw materials obtained by final filtration, and the transmission of solid beverage raw material powder between filter tanks is realized by setting the height difference of each filter tank, which avoids the setting of extraction devices a...

Embodiment 2

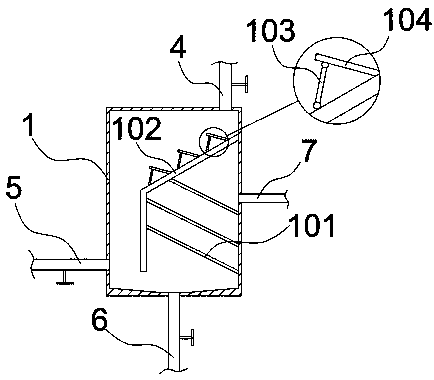

[0026] The further optimization scheme of this embodiment on the basis of embodiment 1 is as follows: figure 2 As shown, the inner wall of the primary filter tank 1 is obliquely connected with a partition 102. There is a gap between the partition 102 and the inner wall of the other side of the primary filter tank 1 and there is a gap between the vertically downward extension and the inner bottom surface of the primary filter tank 1. The inside of the partition 102 is connected to the primary filter tank 1. A filter plate 101 is obliquely connected between the inner walls of the filter tank 1, and a transfer pipe 7 is connected to the inner wall of the primary filter tank 1 above the filter plate 101, and the partition plate 102 is used to control the whereabouts of the solid beverage raw materials entering the primary filter tank 1. The buffering effect makes it slide down to the bottom of the primary filter tank 1 and filter upward through the filter plate 101, and then disch...

Embodiment 3

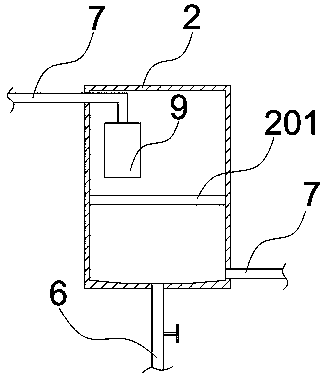

[0029] In this embodiment, on the basis of embodiment 1, the further optimization scheme is as follows: Figure 3-5As shown, the intermediate filter tank 2 is provided with a mixer 9 connected to the discharge port of the transfer pipe 7, and a second filter plate 201 is provided below the mixer 9, and the falling raw materials are buffered by the mixer 9 to avoid its falling speed. Too fast can also process the raw materials entering the mixer 9 to reduce the fineness of raw material particles and avoid the occurrence of agglomeration, which is also beneficial to the filtering effect of the second filter plate 201 on the raw materials.

[0030] The mixer 9 includes a housing 901, the middle part of the housing 901 is provided with a rotatable rotating shaft 904, and the rotating disc 903 is evenly distributed on the rotating shaft 904, and the rotating discs 903 are connected by an elastic rope 902 and the end of the elastic cord 902 is connected to the top wall of the housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com