Welding and repairing method and device for thin-walled part

A welding repair and parts technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of burn-through, small deformation, thermal deformation, etc., to achieve efficient cooling, prevent deformation or burn-through effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

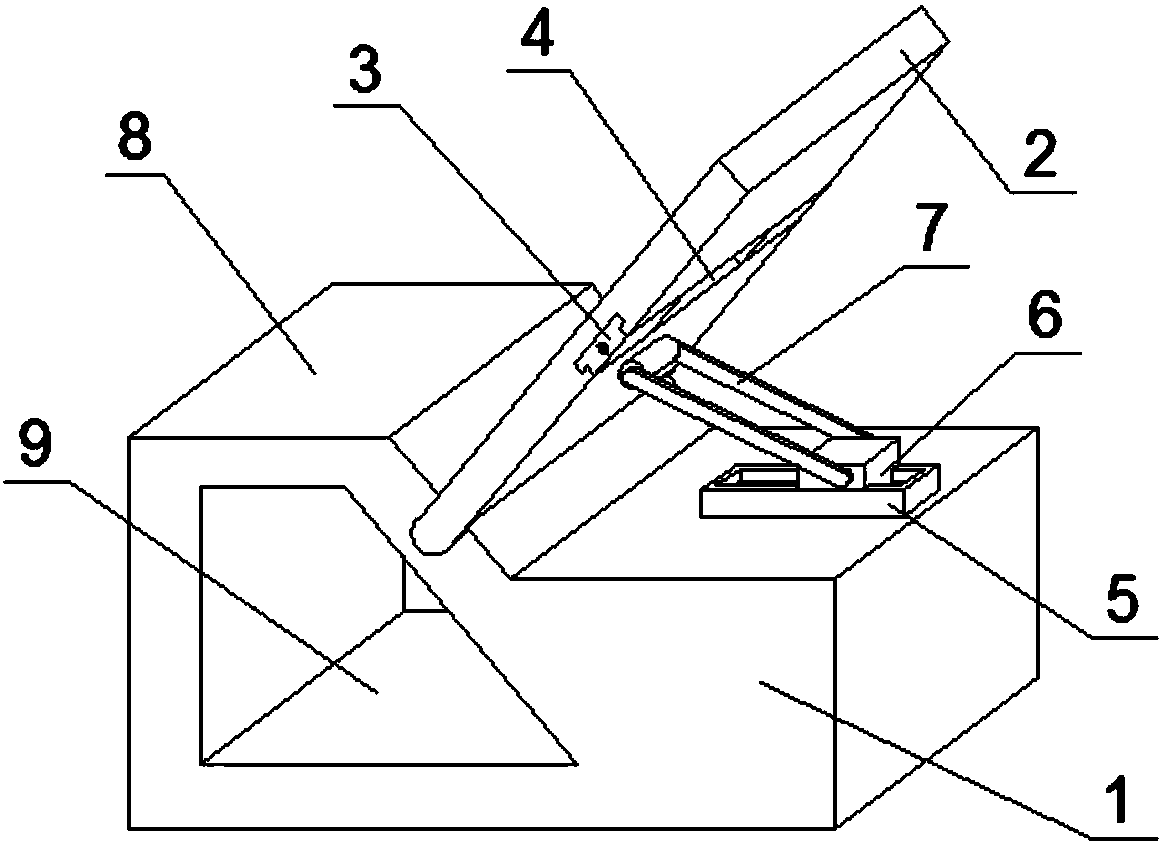

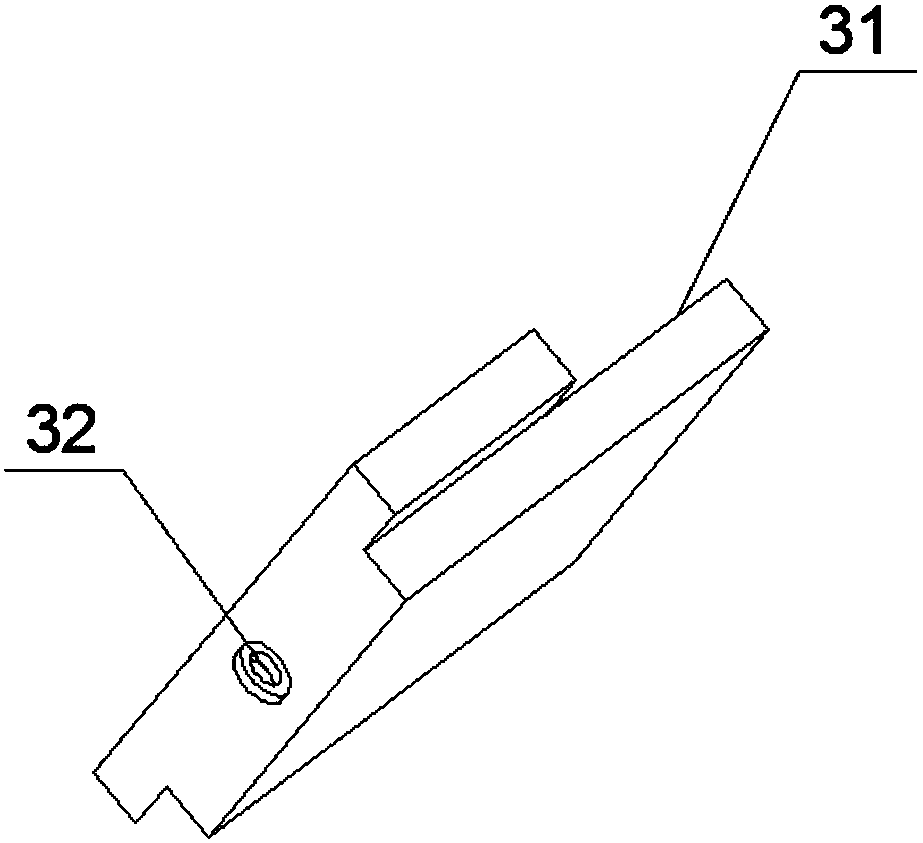

[0024] Such as figure 1 and figure 2 As shown, the welding repair device for thin-walled parts provided in this embodiment includes a base 1 and a welding platform 2. A boss 8 is provided on one side of the upper surface of the base 1, and a sliding seat 5 is installed on the other side. The boss 8 is close to One side of the sliding seat 5 is provided with an inclined surface, and the bottom of the welding platform 2 is hinged on the inclined surface of the boss 8; the welding platform 2 has a welding hole 4, and the thin-walled parts are placed on the welding platform 2 at the welding hole 4 Welding is carried out on the surface, and the two sides of the welding hole 4 are slidably installed with a bearing plate 3. The cross-sectional shape of the bearing plate 3 is T-shaped, and the inner side of the bearing plate 3 is provided with a bearing groove 31, which can be used to carry thin-walled parts , the outer side of the bearing plate 3 is provided with a pull ring 32, ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com