A method for robot self-calibration

A robot and self-calibration technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of harsh conditions, increase the difficulty of calibration experiments, and affect the calibration accuracy, and achieve low cost, reduce difficulty, and improve calibration accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

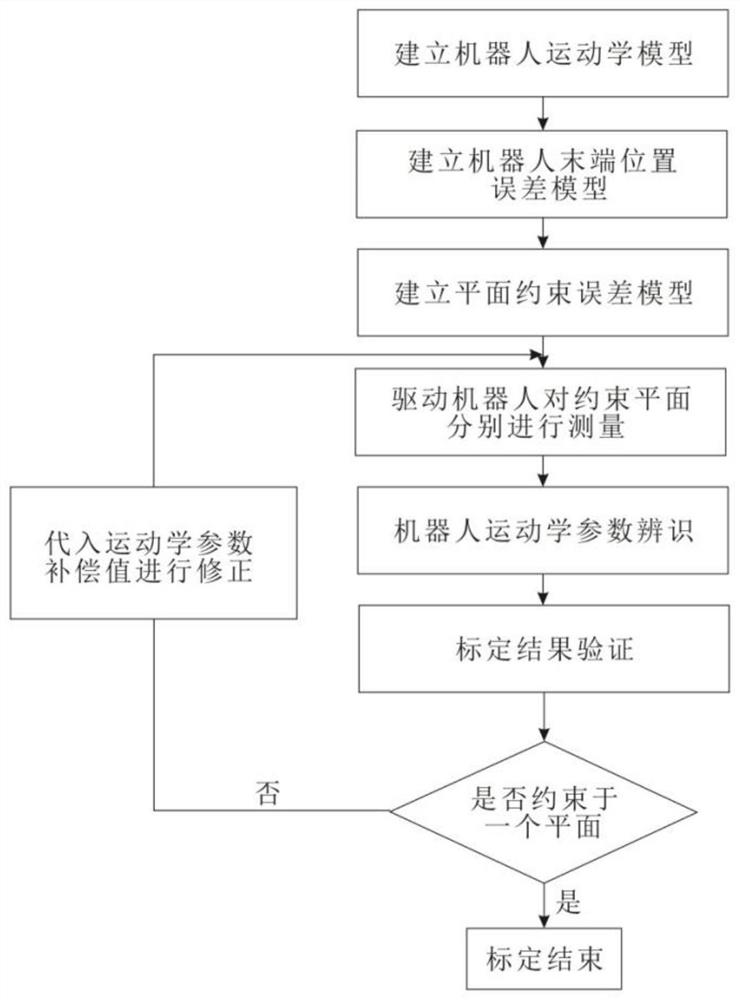

[0058] Such as figure 1 Shown is a schematic flow chart of the robot self-calibration method based on the plane constraint error model described in the first embodiment of the present invention. The so-called calibration is to use advanced measurement means and appropriate parameter identification methods to identify the accurate parameters of the robot model, thereby improving Process with robotic precision. In order to solve the problems of high cost of measuring instruments, complicated installation and operation, professional and technical personnel are required to operate these instruments, and the space position of the calibration block is demanding.

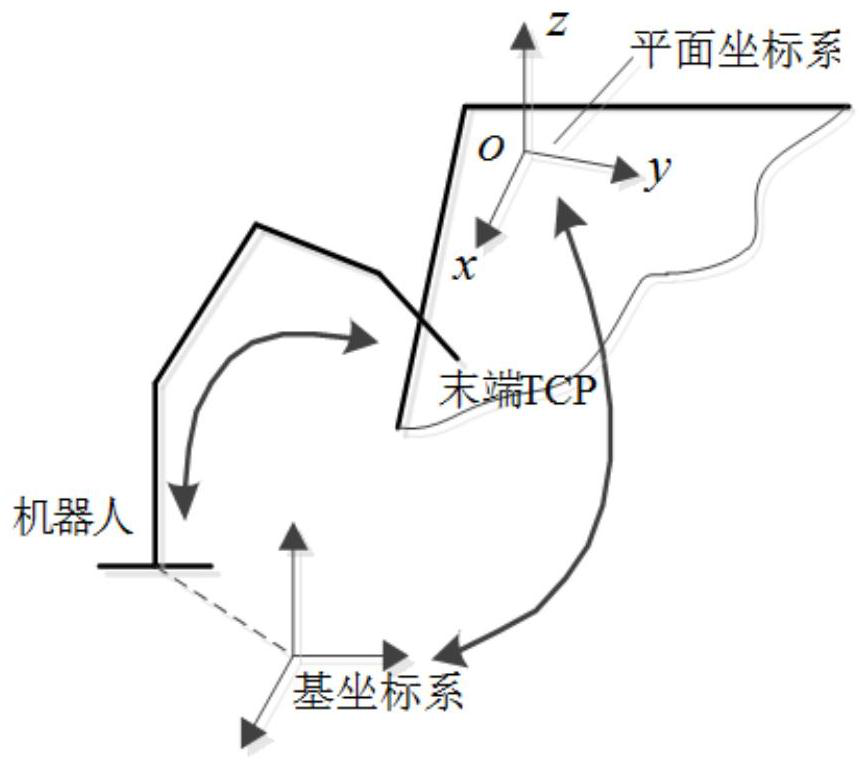

[0059] This embodiment provides a robot self-calibration method based on a plane-constrained error model, which utilizes the establishment of a plane-constrained error model to self-calibrate the robot. The measurement of kinematic parameters is usually identified by internal sensor data and external measurement device dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com